Rotary separating valve and method for prolonging service life of oxygen generator

A separation valve and rotary technology, applied in sliding valve, control valve, valve device and other directions, can solve the problems affecting the life of oxygen generator, discount of molecular sieve life, attenuation of molecular sieve life, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

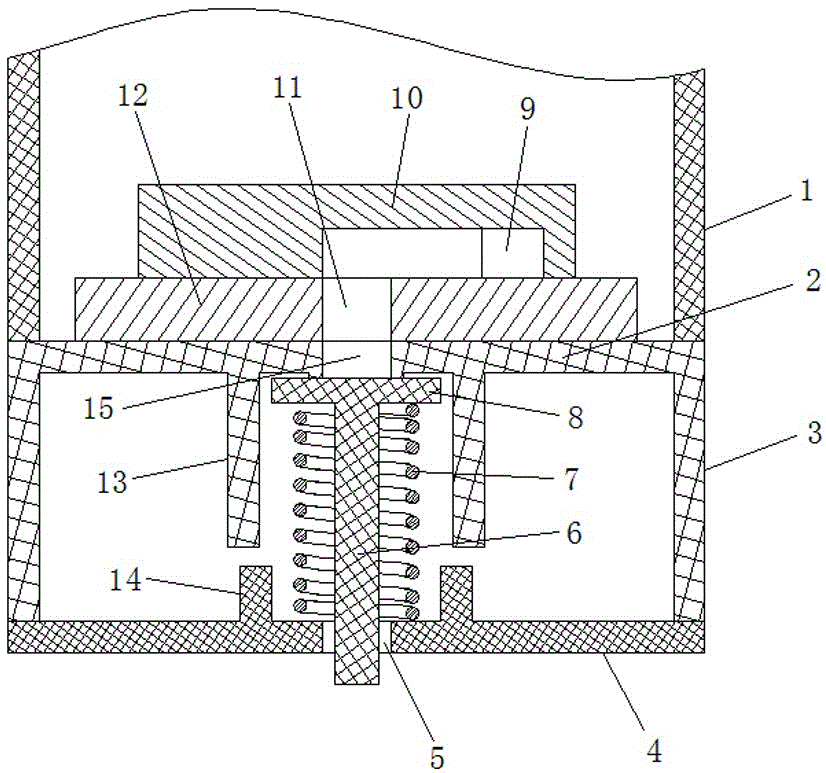

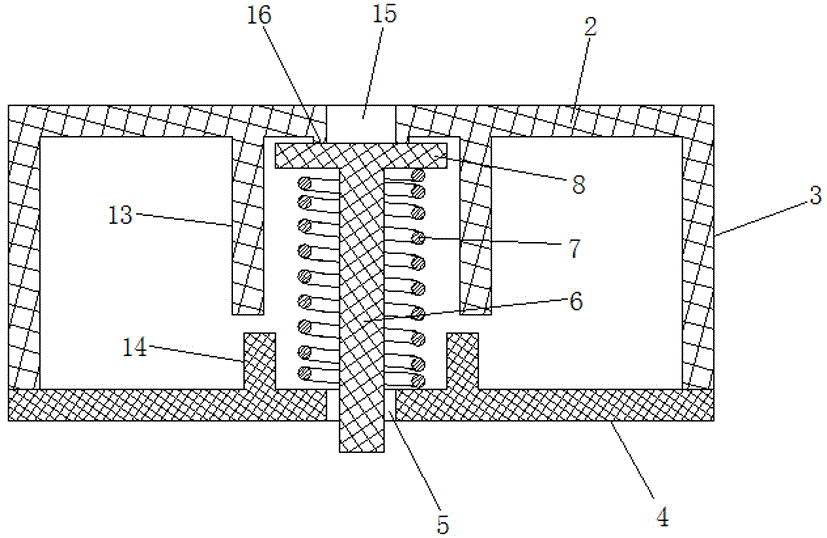

[0030] Such as figure 1 and figure 2 As shown, the one-way valve is located directly below the nitrogen exhaust port 11, the one-way valve includes a sealing rubber plug 8 and a one-way limit spring 7, and the sealing rubber plug 8 is located directly below the vent hole 15, The diameter of the sealing rubber plug 8 is larger than the diameter of the vent hole 15, and a one-way limit spring 7 is arranged under the sealing rubber plug 8, and the one-way limiting spring 7 is arranged on the bottom plate of the sealing rubber plug 8 and the bottom case 4 between. Described ventilation hole 15 below is provided with sealing rubber plug 8, and the diameter of sealing rubber plug 8 is larger than the diameter of ventilation hole 15, on the one hand, when machine is not working, sealing rubber plug 8 in the one-way valve is in one-way limit position. Under the force of the spring 7, it moves upwards to tightly cover the vent hole 15, that is, to seal the nitrogen discharge port 11...

Embodiment 2

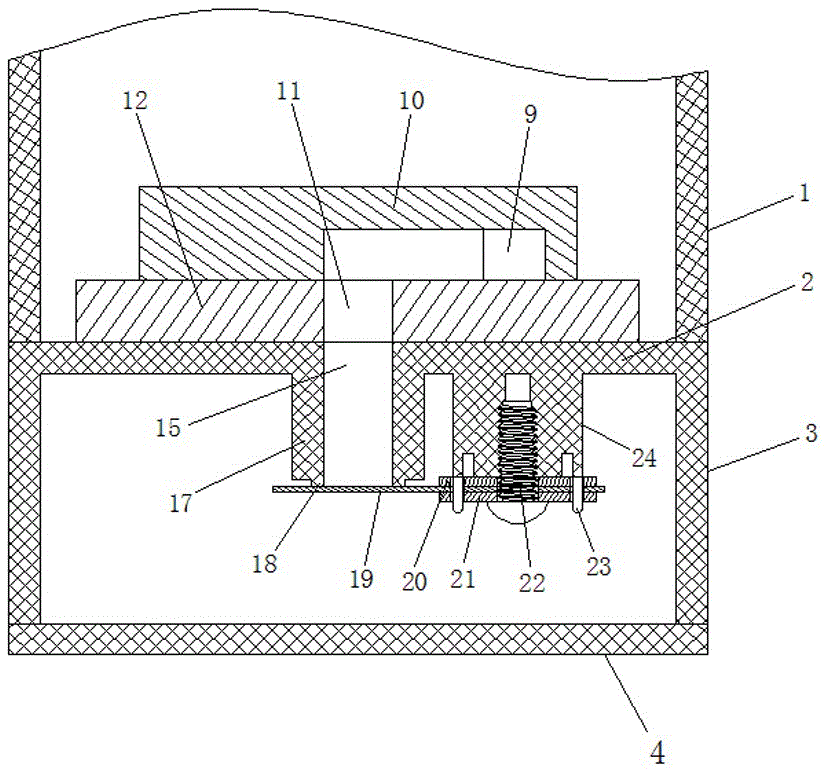

[0034] Such as image 3 and Figure 4 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the structure and installation position of the check valve are different from those of the check valve in Embodiment 1. In this embodiment In the embodiment, the bottom of the air hole 15 on the top plate 2 of the middle shell 3 is provided with a downward cylindrical exhaust channel 17, and the end of the exhaust channel 17 is provided with an inwardly contracted sealing port 18, and the one-way valve Located below the sealing port 18, the one-way valve is connected with the middle shell 3 through the fixing screw 22, and the one-way valve is connected with the middle shell 3 stably, firmly and quickly through the fixing screw 22. The one-way valve includes a sealing shrapnel 19, an upper gasket 20 and a lower gasket 21, and the middle shell 3 is provided with a valve seat 24 for installing a one-way valve on on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com