Magnesium battery

A magnesium battery and magnesium alloy technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of large positive shift of working potential, difficult to meet industrial needs, low anode utilization rate, etc., to reduce the difference in electrochemical activity, The effect of reducing the self-corrosion rate and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

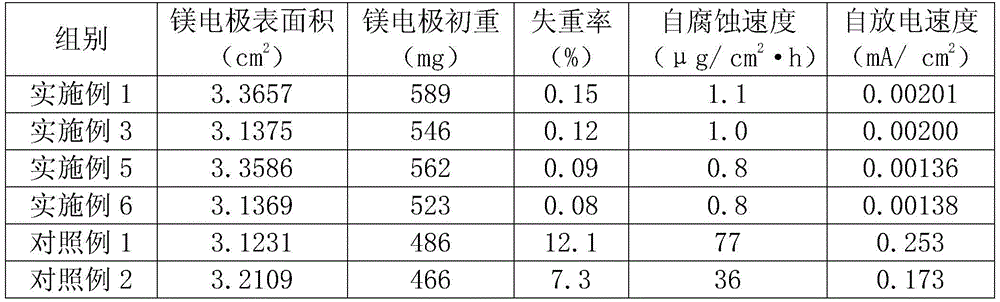

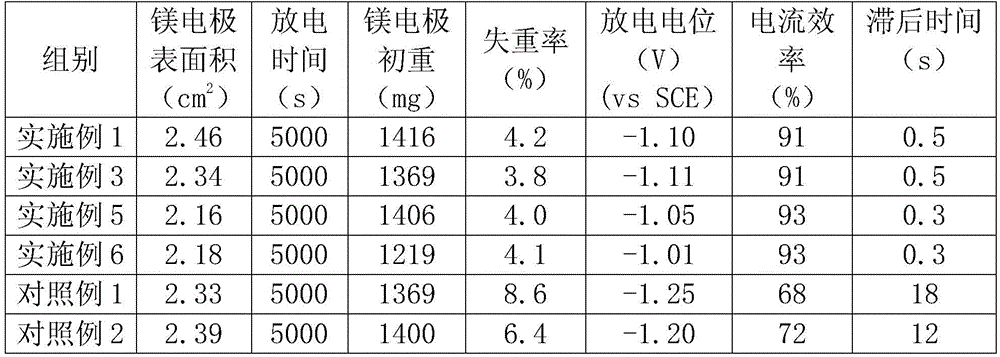

Examples

Embodiment 1

[0017] Magnesium electrode: based on the total weight of the magnesium alloy, the magnesium alloy contains Er0.01%, Sn0.05%, Y0.01%, Ce0.01%, Nd0.1% and In0.02%, and the balance is Mg.

[0018] The electrolyte is 1mol / L Mg(ClO 4 ) 2 solution, add 0.1% Li 2 CrO 4 .

Embodiment 2

[0020] Magnesium electrode: based on the total weight of the magnesium alloy, the magnesium alloy contains Er0.3%, Sn0.5%, Y0.03%, Ce0.1%, Nd0.5% and In0.2%, and the balance is Mg.

[0021] The electrolyte is 1mol / L MgBr 2 solution, add 0.1% Na 2 CrO 4 .

Embodiment 3

[0023] Magnesium electrode: based on the total weight of the magnesium alloy, the magnesium alloy contains Er0.01%, Sn0.05%, Y0.01%, Ce0.01%, Nd0.1%, In0.02%, Al1%, Zn 0.5%, and the balance is Mg.

[0024] The electrolyte is 1mol / L Mg(ClO 4 ) 2 solution, add 0.1% Li 2 CrO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com