Microwave output window and manufacturing method thereof

A manufacturing method and output window technology, which is applied in the direction of waveguide devices, discharge tubes, electrical components, etc., can solve the problems of low power capacity, easy to cause oscillation mode, and large dielectric loss of ordinary box-shaped windows, so as to avoid high-frequency shock Wear damage, improve welding reliability, the effect of small dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to specific embodiments and drawings.

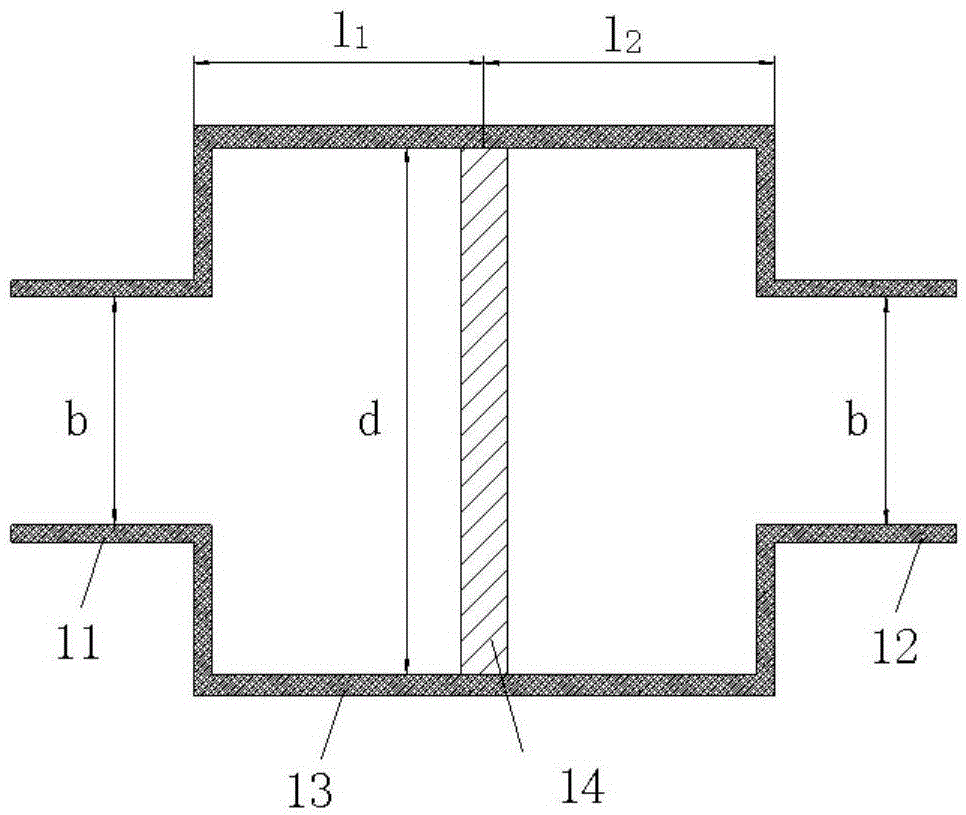

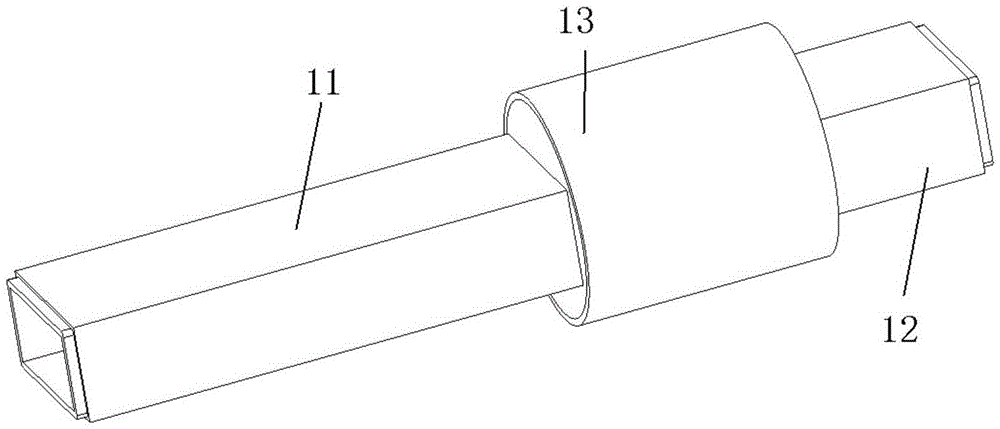

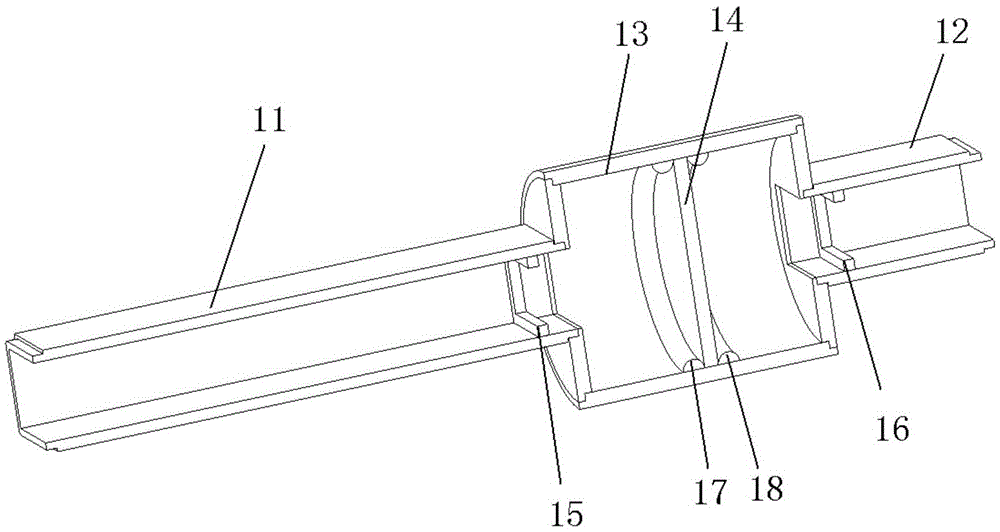

[0037] As a key component of a high-power microwave electronic system, the microwave output window transmits high-frequency power while maintaining good air tightness inside the device. The commonly used box-type output window seals a disc dielectric sheet in a circular waveguide with the same cross section, and the two ends are connected to the rectangular waveguide. A microwave output window with high power capacity is of great significance and urgent need. How to prevent the dielectric sheet from being broken down by the high-frequency electric field to increase the power capacity of the output window is an important issue. The present invention provides a microwave output window that can avoid The dielectric sheet is broken down by the high-frequency e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com