Rigid-flex board with different flexible shapes and preparation method thereof

A rigid-flex board and shape technology, applied in multi-layer circuit manufacturing, printed circuit components, etc., can solve the problems of unable to meet the installation requirements of flexible areas, too thick flexible areas of branch lines, and the area occupied by flexible areas, so as to save a lot of space. Branch current wiring space, improve randomness, and meet the effect of bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present application will be further elaborated below by way of examples.

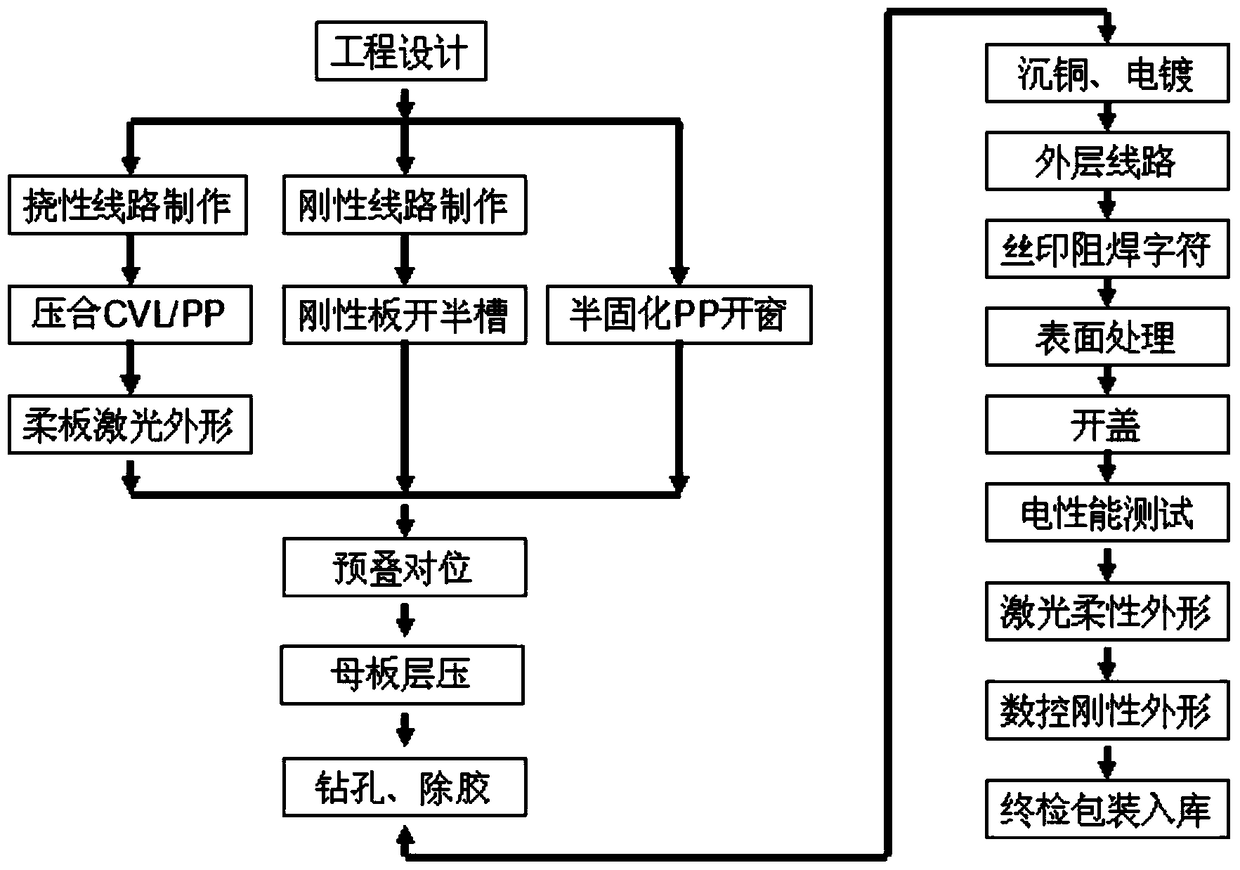

[0037] A kind of preparation method of the rigid-flex board with different flexible shapes in this embodiment (flow chart is as follows figure 2 shown), including the following steps:

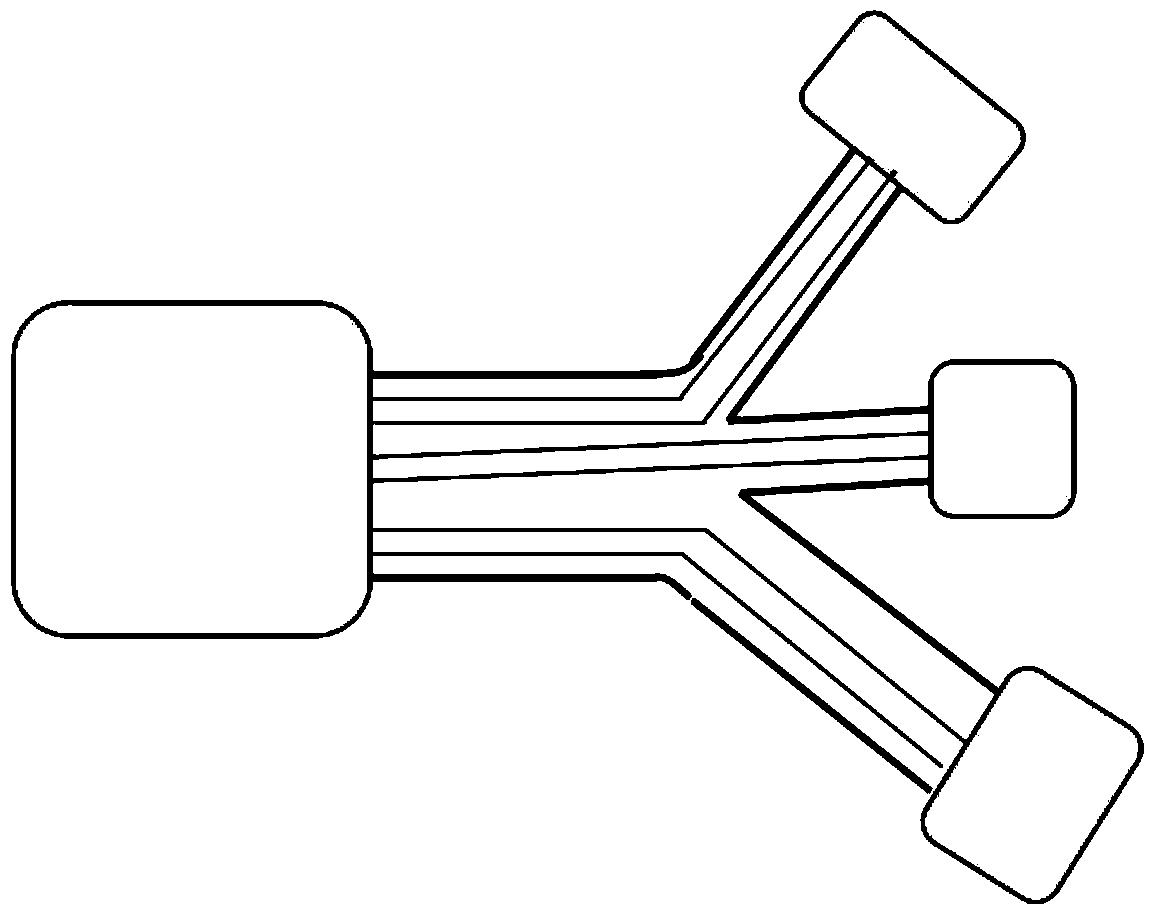

[0038] (1) Make at least two flexible core boards, make circuit patterns on the surface of each flexible core board according to conventional methods, and then perform laser shape operations (such as image 3 shown);

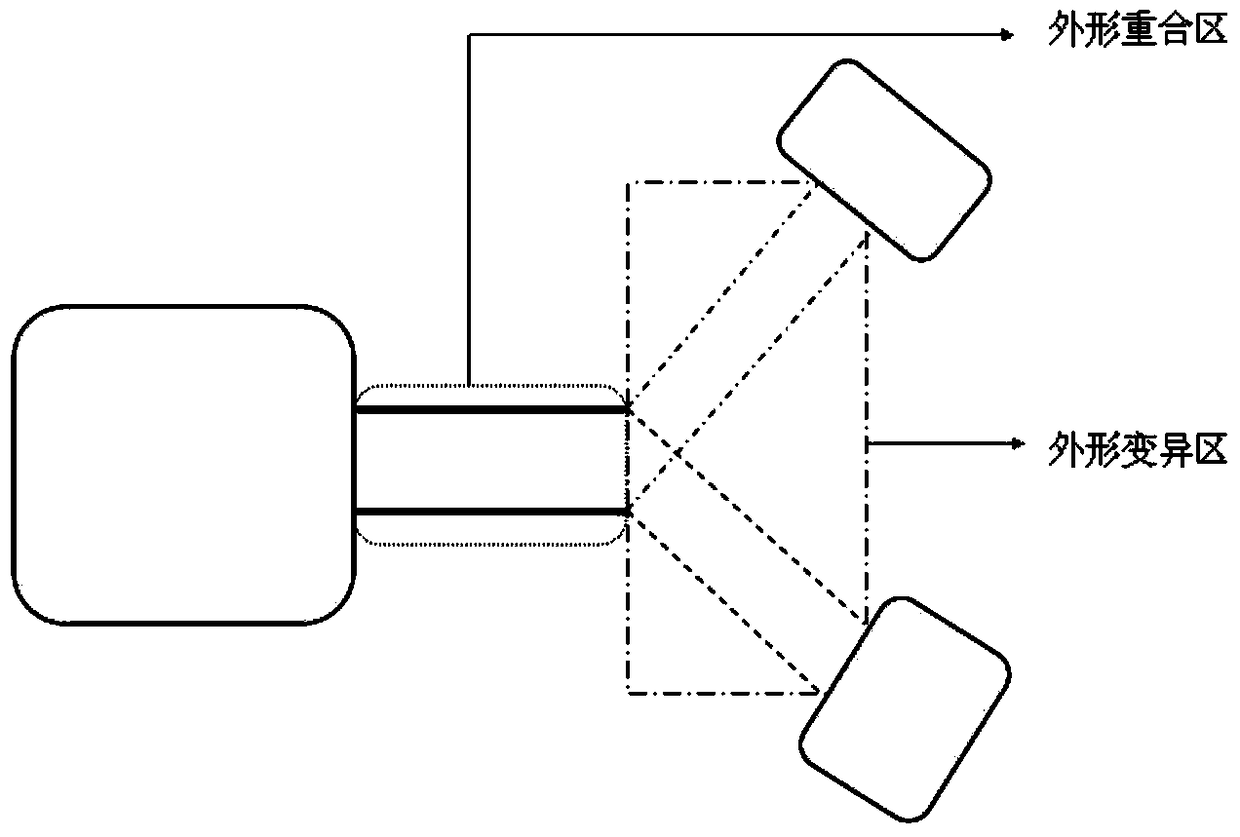

[0039] The flexible core board is provided with a shape overlapping area and a shape variation area, and the area of the laser shape operation is the shape variation area; the shape line of the laser shape operation extends to more than 0.15mm in the shape overlap area;

[0040] This operation can ensure that the flexible shape variation area will not be damaged. If it is a one-time molding, this area is easily damaged by a laser or a milling machine; and the outline line of the laser shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com