Mass transfer apparatus

A circulating and high-efficiency technology, applied in the field of mass transfer devices and electric equipment, can solve the problems of increasing the volume and power of heaters, limiting the length of a reaction, and increasing energy consumption, so as to achieve high space utilization, prolong reaction and Operating time and the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

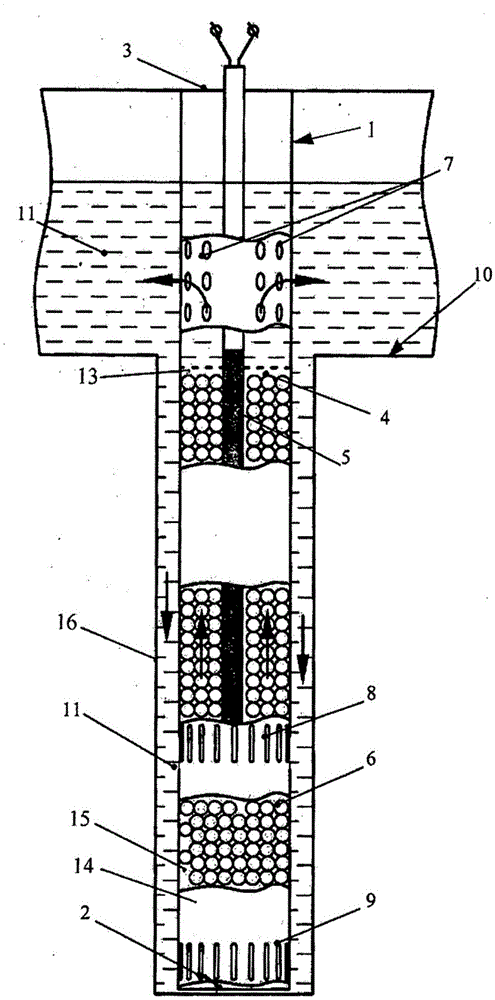

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown (the following are all conventional numbers in this field), wherein: 1—shell, 2—bottom, 3—top, 4—restrictive porous grid, 5—electric heater, 6—solid particle oxidant, 7—exit, 8—inlet, 9—liquid outlet, 10—heat carrier storage tank, 11—liquid metal heat carrier, 13—flow reaction chamber, 14—bottom of oxidant storage chamber (cup-shaped body), 15—particle oxidant storage chamber, 16 - Outer cover.

[0022] The device according to the embodiment of the present invention comprises a space surrounded by a housing 1 and composed of a bottom 2 and an annular top 3 . In this space, a flow reaction chamber 13 is arranged below the liquid level of the liquid metal heat carrier 11, and a restrictive porous grid 4 is arranged on the top of the flow reaction chamber 13, the purpose of which is to restrict the solid particle oxidant 6 under the acti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap