Catalytic cracking light product desulfurization method, and method and device for catalytic cracking production of low-sulfur light oil product

A technology of catalytic cracking and light products, which is applied in the field of desulfurization and separation of catalytic cracking rich gas and naphtha, and hydrocarbon oil desulfurization. Effects of saturation and saving hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

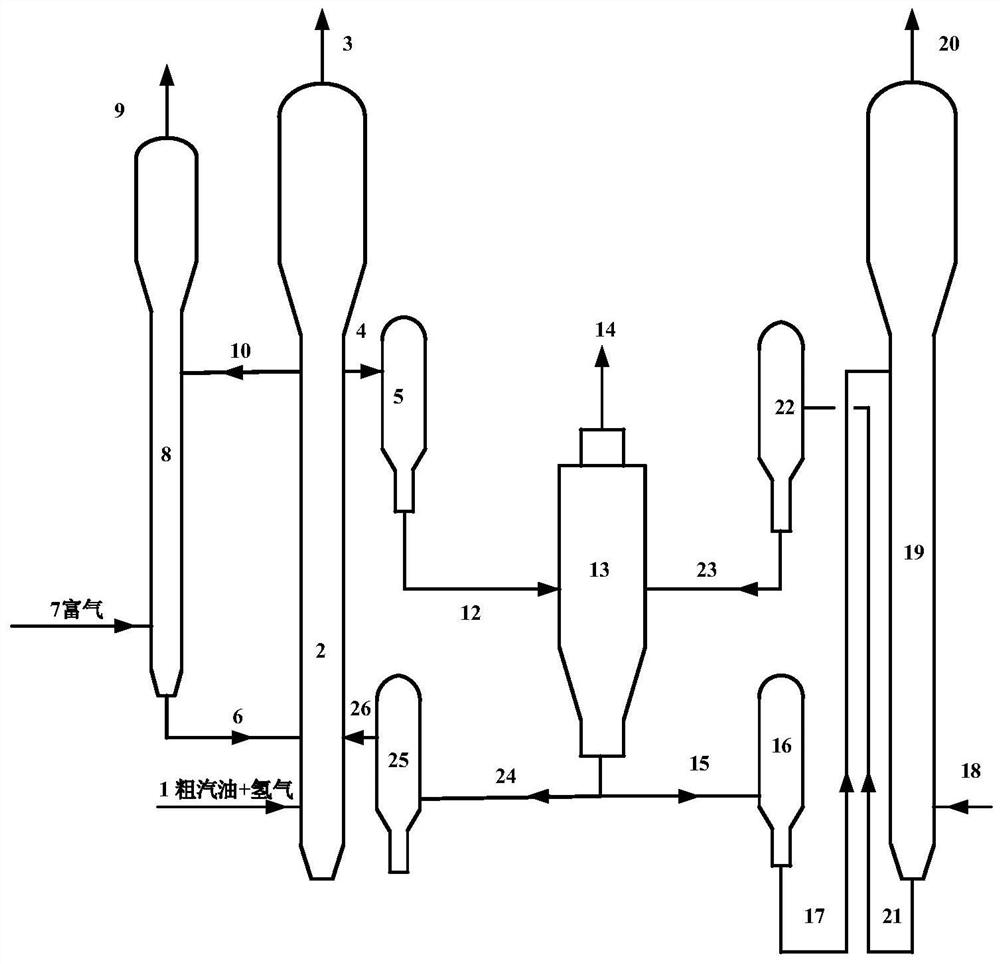

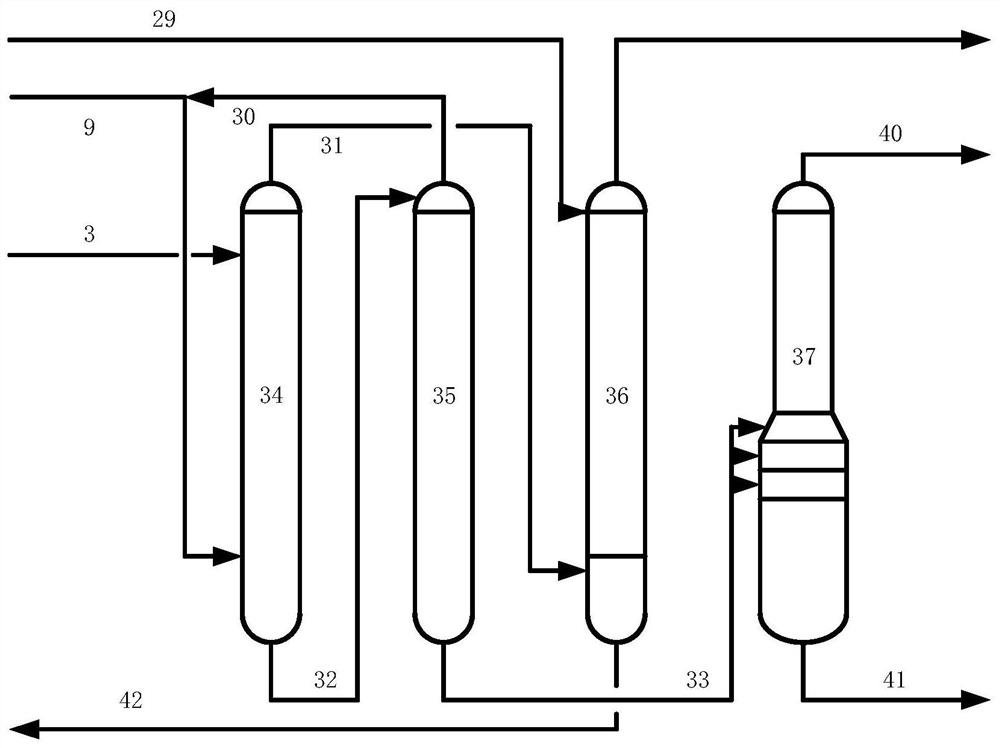

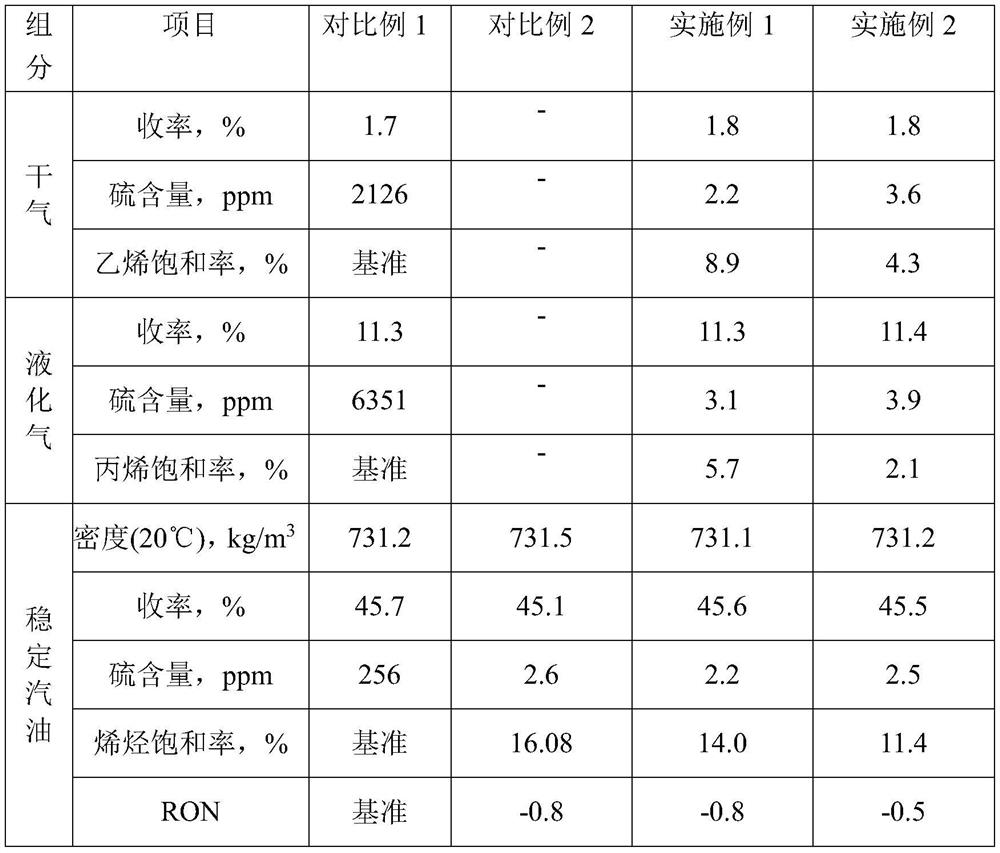

[0072] Using rich gas and crude gasoline as raw materials, it first enters the adsorption desulfurization reaction unit, and then enters the absorption stabilization unit for separation. figure 1 The process of adsorption desulfurization unit and the process of absorption stabilization unit are as attached figure 2 As shown, the first desulfurization reactor is a small fixed fluidized bed reactor, and the second desulfurization reactor is a countercurrent reactor. The desulfurization adsorbent used is FCAS. The desulfurization adsorbent from the reducer enters the first desulfurization reactor from the bottom, and naphtha and hydrogen enter the first desulfurization reactor from the bottom to contact with the desulfurization adsorbent for adsorption and desulfurization. After the reaction is completed, The reaction oil gas is separated from the desulfurization adsorbent to obtain a mixture of desulfurized naphtha and hydrogen; part of the desulfurization adsorbent on the top ...

Embodiment 2

[0074] Use as attached figure 1 And attached figure 2 The flow process of the desulfurization and separation method shown in the adsorption desulfurization unit and the absorption stabilization unit uses rich gas and naphtha as raw materials, adopts the same reaction process and desulfurization adsorbent as in Example 1, the difference is that the first desulfurization The reactor is at a reaction temperature of 430°C, a reaction pressure of 1.4MPa, and a weight hourly space velocity of 8h -1 , under the reaction conditions of hydrogen oil volume ratio of 100. Preheat the rich gas to 430°C and enter the second desulfurization reactor. At a reaction temperature of 445°C, a reaction pressure of 0.5MPa, and a weight hourly space velocity of 12h -1 The first desulfurization reactor obtains desulfurized naphtha and hydrogen, and the second desulfurization reactor obtains desulfurized rich gas. Wherein, 60% of the position from bottom to top of the first desulfurization reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com