Preparation method for doped iron oxide nanorod catalyst

An iron oxide nanometer, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of less research, and achieve low cost, good stability, and simple and easy preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

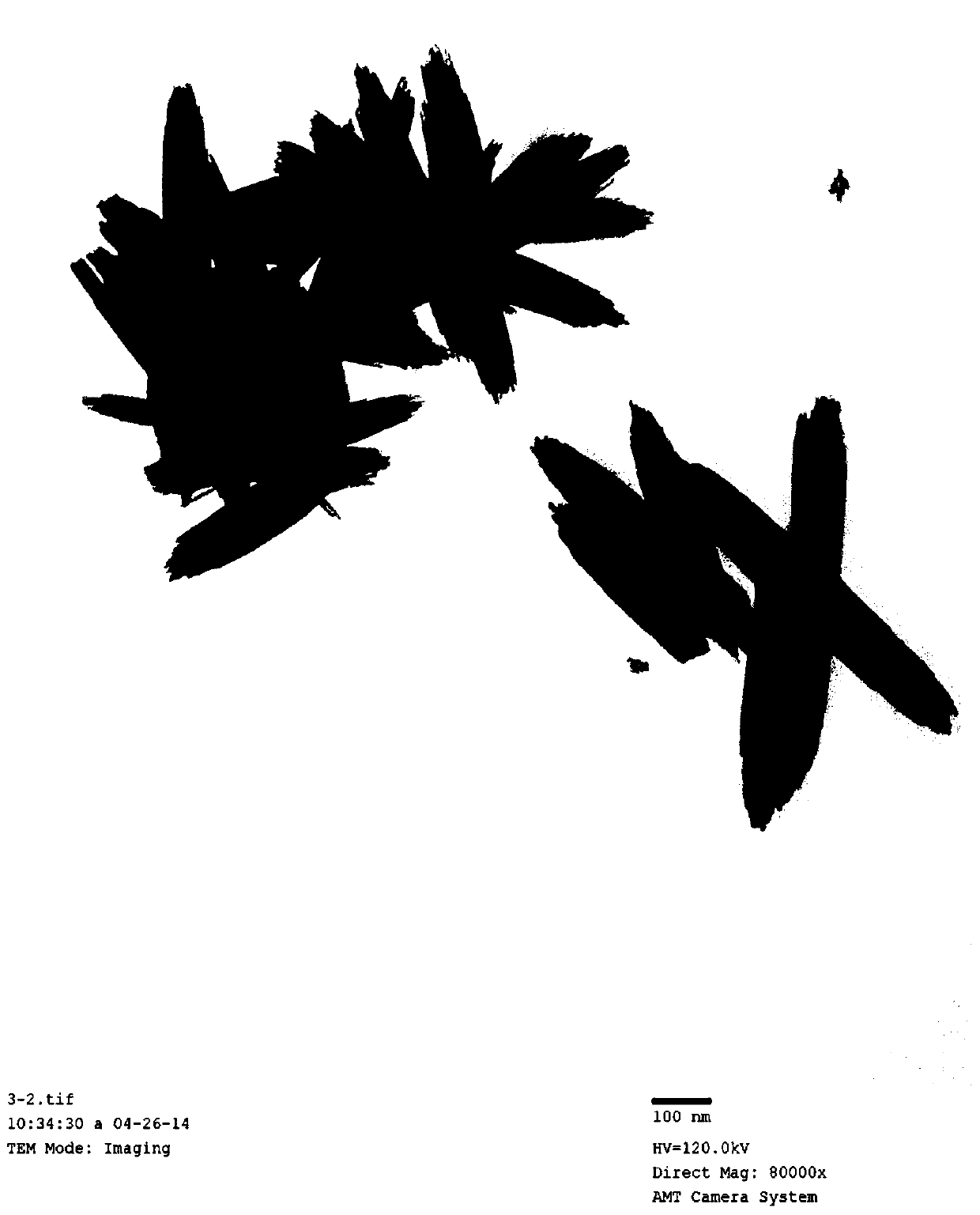

Image

Examples

Embodiment 1

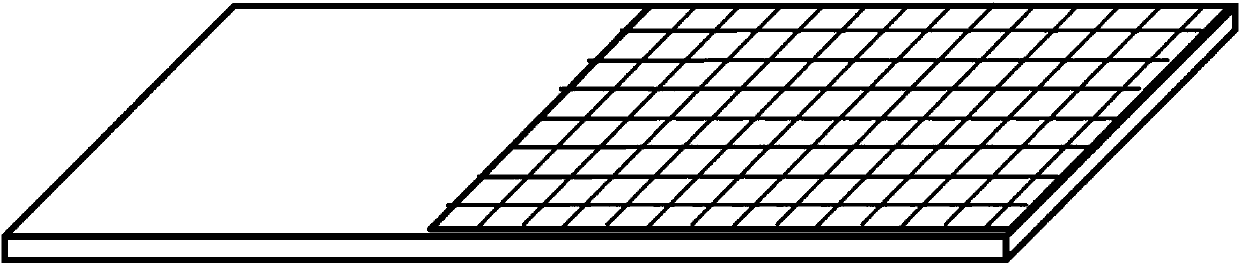

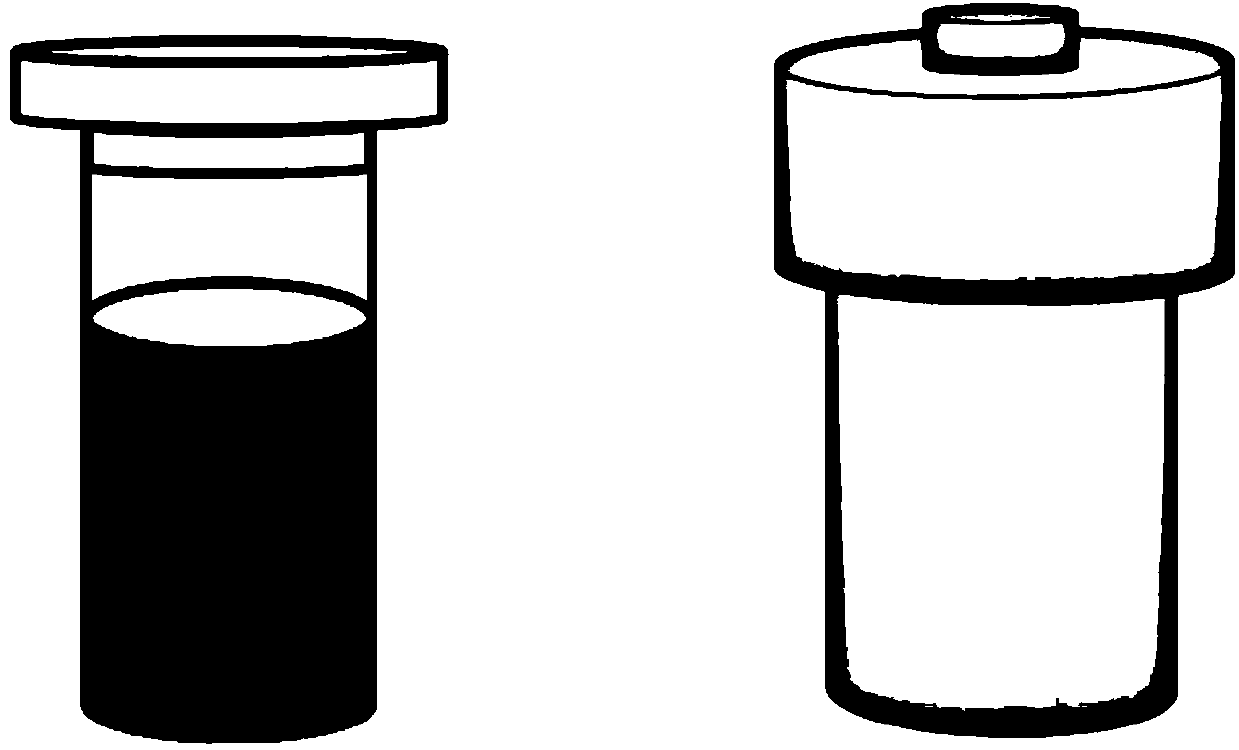

[0033] Using conductive glass (FTO) as a conductive substrate, the substrate was subjected to the above-mentioned pretreatment process. The deposition area of the fixed sample on the FTO conductive surface is 2×2cm 2 , and the rest is sealed with insulating tape; place the pretreated conductive glass in the inner tank of the hydrothermal reactor, with the conductive surface facing the center of the inner tank of the hydrothermal reactor and fix the upper half with insulating tape. Add 0.01mol / LCo(NO 3 ) 2 , 1mol / LNaNO 3 and 0.1mol / LFeCl 3 A mixed solution of water / polyethylene glycol (volume ratio 5:1) is used as a precursor; use 2M concentrated hydrochloric acid solution to adjust the pH value of the solution in the liner to 1, and stir evenly; seal the hydrothermal kettle and put it into the oven Heat at 100°C for 4 hours; after the reaction is completed, cool the hydrothermal kettle to room temperature with the furnace; take out the conductive glass from the hydrother...

Embodiment 2

[0035] A stainless steel substrate was used as the conductive substrate, and the substrate was subjected to the above-mentioned pretreatment. The deposition area of the sample on the surface of the conductive glass is fixed, and the rest is sealed with insulating tape; the pretreated conductive substrate is placed in the inner tank of the hydrothermal kettle, and the conductive surface faces the center of the kettle. Add 0.01mol / LTiCl to the inner tank of the hydrothermal kettle 4 , 1mol / LNaNO 3 and 0.075mol / LFeCl 3 A mixed solution of water / polyethylene glycol (volume ratio 5:1); adjust the pH value of the solution in the liner to 1.69 with 0.5M hydrochloric acid solution, and mix well; put the hydrothermal kettle into the oven for 150 ℃ for 4 hours; after the reaction was completed, the hydrothermal kettle was rapidly cooled to room temperature; the Ti substrate was taken out from the hydrothermal kettle, and the insulating tape was removed after cleaning with deionized ...

Embodiment 3

[0037] A gold-plated FTO was used as the conductive substrate, and the substrate was subjected to the above-mentioned pretreatment. The deposition area of the sample on the surface of the conductive glass is fixed, and the rest is sealed with insulating tape; the pretreated conductive substrate is placed in the inner tank of the hydrothermal kettle, and the conductive surface faces the center of the inner tank. Add 0.05mol / LCo(NO 3 ) 2 , 1mol / LNaNO 3 and 0.1mol / LFeCl 3 Mixed solution of water / polyethylene glycol (volume ratio 5:1); use 0.5mol / L hydrochloric acid solution to adjust the pH value of the solution in the liner to 1.5, and mix well; seal the hydrothermal kettle and put it into the oven Heating at 200°C for 24 hours; after completion, the hydrothermal kettle was rapidly cooled to room temperature; the FTO was taken out from the hydrothermal kettle, and the insulating tape was removed after cleaning with deionized water, and then the conductive film sample was pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com