Baeyer-Villiger oxidation reaction catalyst and preparation method and application thereof

A technology of oxidation reaction and catalyst, applied in the direction of physical/chemical process catalyst, catalytic reaction, organic compound/hydride/coordination complex catalyst, etc. Explosion and other problems, to achieve the effect of novel catalyst structure, constant catalytic activity and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

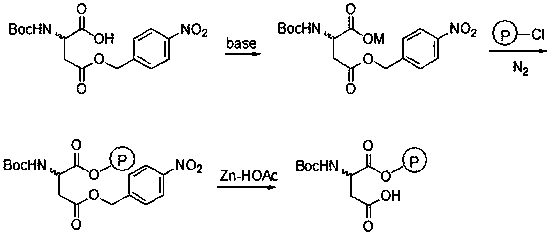

[0021] In a 250mL four-neck flask, add 50mL of water, 2.33g (0.012mol) of CsHCO 3 and 50mL of methanol, stirred, added 3.09g (0.01mol) N-Boc-aspartic acid-4-(4-nitro)benzyl ester, reacted at room temperature for 10min, and added 0.65g (0.003mol) CsHCO 3 , control the pH of the system to 8-9, after the reaction is completed, the methanol is distilled off and dried to obtain 4.40 g of white cesium salt of N-Boc-aspartic acid-4-(4-nitro)benzyl ester.

[0022] In 20 mL of a mixed solvent of DMF and N-methylpyrrolidone (V / V=13:7), add 0.62 g (1.4 mmol) of cesium salt of N-Boc-aspartic acid-4-(4-nitro)benzyl ester , 1.0g Merrifield resin (chlorine content: 0.7mmol / g), N 2 Under protection, stir the reaction at 50°C for 36h, filter, and wash the resin with 5mL×3H 2 O, washed with 5 mL×3 DMF, 5 mL×3 dichloromethane, and dried under vacuum to obtain 1.18 g of the product.

[0023] Add 1.0 g of the resin prepared above into 10 mL of glacial acetic acid (mass fraction: 90%), cool to 0...

Embodiment 2

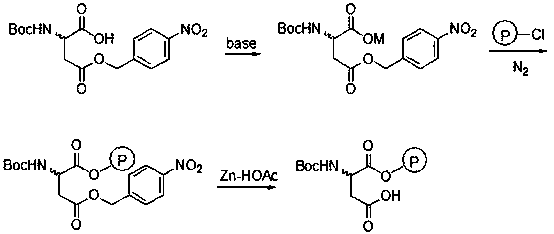

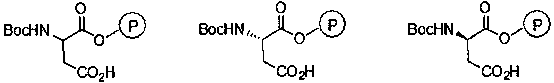

[0026] Substitute (S)-N-tert-butoxycarbonyl-aspartic acid-4-(4-nitro)benzyl ester for N-tert-butoxycarbonyl-aspartic acid-4-(4-nitro)benzyl ester , and other operations were the same as in Example 1 to obtain (S)-N-tert-butoxycarbonyl-aspartic acid catalyst supported by Merrifield resin, with a loading capacity of 0.66 mmol / g.

Embodiment 3

[0028] Substitute (R)-N-tert-butoxycarbonyl-aspartic acid-4-(4-nitro)benzyl ester for N-tert-butoxycarbonyl-aspartic acid-4-(4-nitro)benzyl ester , and other operations were the same as in Example 1 to obtain (R)-N-tert-butoxycarbonyl-aspartic acid catalyst supported by Merrifield resin, with a loading capacity of 0.67 mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com