Overflow-circulation classification method for diamond micro-powder

A diamond micropowder and grading method technology, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of large particle size distribution range, diamond micropowder pollution, and low efficiency of grading methods, and achieve human interference The effect of less, less impurities and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The described diamond powder overflow circulation classification method comprises the following steps:

[0022] (1) Constant pressure water supply system: set overflow water pressure and flow constant pressure water supply

[0023] According to the particle size of the diamond powder to be classified, adjust the overflow water pressure of the pressure sensor and the overflow flow of the electromagnetic flowmeter in the constant pressure water supply system, and turn on the water pump to supply water to the overflow barrel of the overflow classification system. It is 0.3MPa, and the overflow flow rate of diamond powder with different particle sizes is as follows:

[0024] Particle diameter μm

Overflow flow m 3 / h

Particle diameter μm

Overflow flow m 3 / h

3-6

0.00967

10-20

0.15467

4-8

0.01933

20-30

0.30935

5-10

0.03802

30-40

0.60581

8-12

0.07573

36-54

1.23739

[00...

Embodiment 2

[0030] The described diamond powder overflow circulation classification method comprises the following steps:

[0031] (1) Constant pressure water supply system: set overflow water pressure and water volume constant pressure water supply

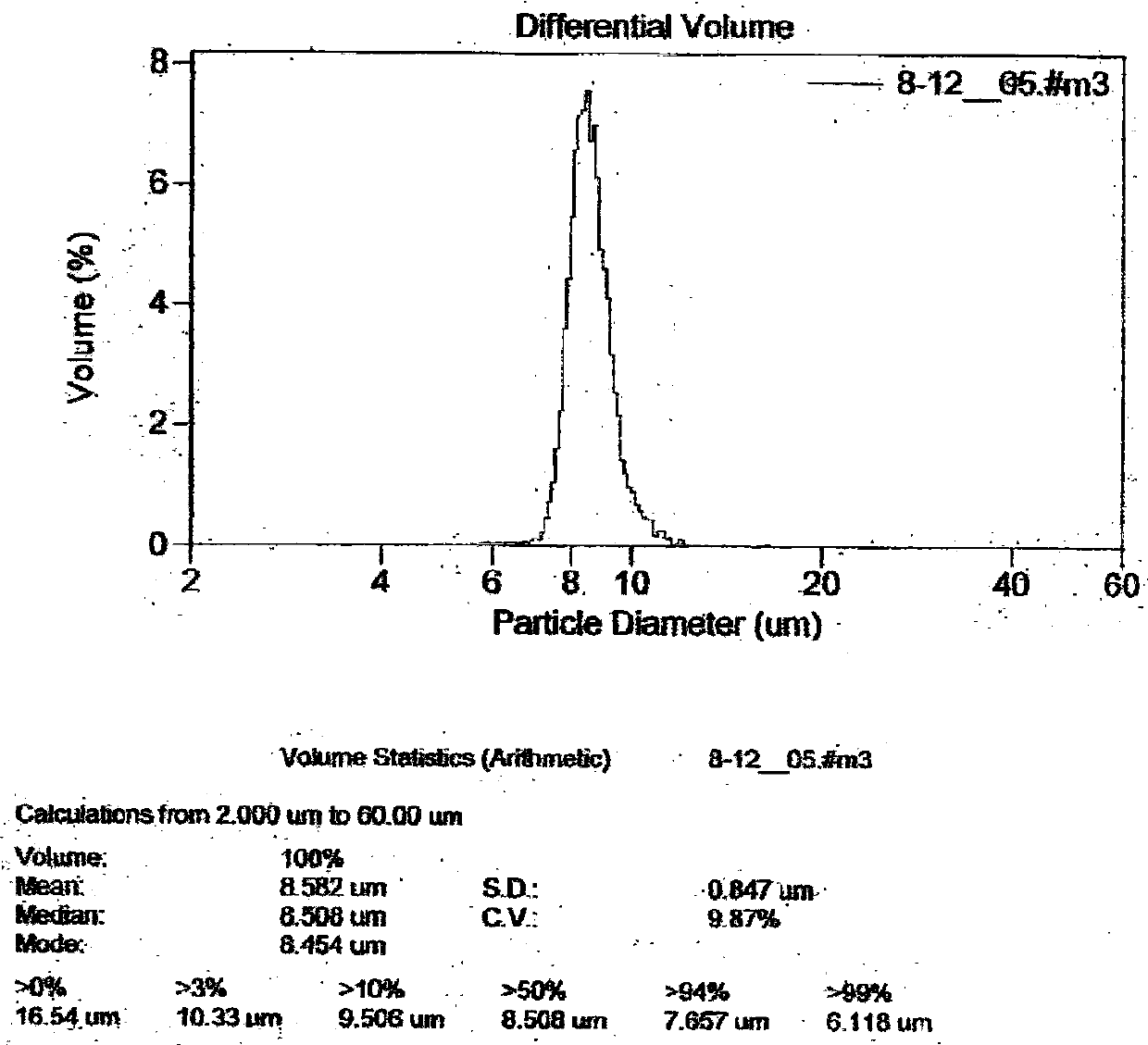

[0032] Diamond micropowder with a particle size of 8-12 μm in the overflow classification, adjust the overflow water pressure of the pressure sensor in the constant pressure water supply system to 0.3MPa, and the overflow flow rate of the electromagnetic flowmeter to 0.07573m 3 / h, turn on the water pump to supply water to the overflow barrel of the overflow classification system;

[0033] (2) Overflow classification system: diamond powder overflow classification

[0034] Stir the diamond micropowder to be classified with deionized water into a slurry and put it into the overflow bucket, add deionized water to the overflow bucket, the height of the water should not exceed the overflow cone, and the concentration of the diamond micropowder i...

Embodiment 3

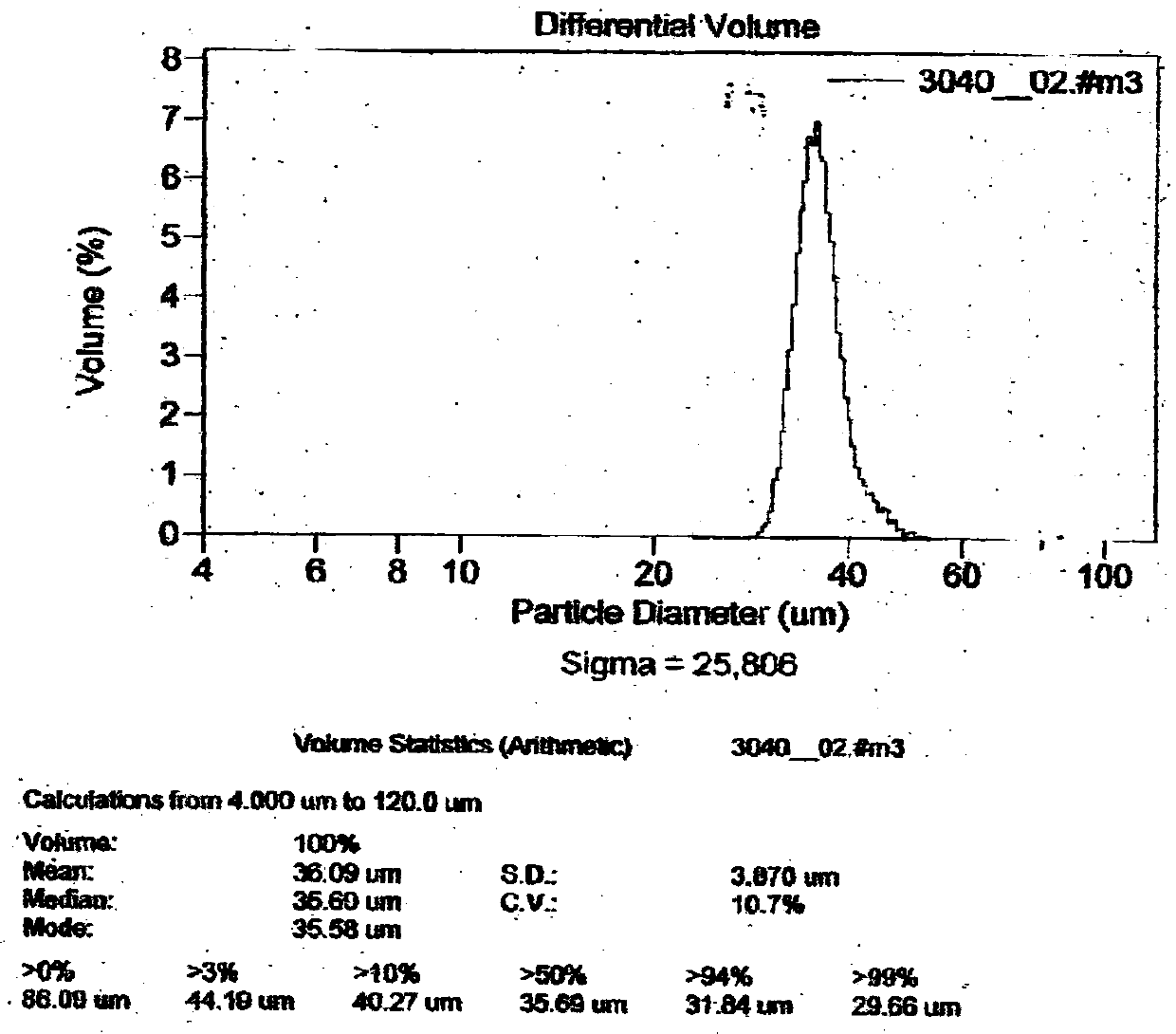

[0039] The described diamond powder overflow circulation classification method comprises the following steps:

[0040] (1) Constant pressure water supply system: set overflow water pressure and water volume constant pressure water supply

[0041] Diamond micropowder with a particle size of 30-40μm for overflow classification, adjust the overflow water pressure of the pressure sensor in the constant pressure water supply system to 0.3MPa, and the overflow flow rate of the electromagnetic flowmeter to 0.60581m 3 / h, turn on the water pump to supply water to the overflow barrel of the overflow classification system;

[0042] (2) Overflow classification system: diamond powder overflow classification

[0043] Stir the diamond powder that needs to be graded with deionized water to form a slurry and put it into the overflow bucket, add deionized water to the overflow bucket, the height of the water should not exceed the overflow cone, and the concentration of the diamond powder in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com