A self-adaptive grinding device for large curved surface grinding

An adaptive, curved surface technology, which is applied in the direction of automatic grinding control devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problem that it is difficult to ensure the integrity and consistency of the workpiece shape and surface, affect the efficiency of grinding, and curved surfaces Poor adaptability and other problems, to achieve the effect of improving processing quality and production efficiency, improving grinding efficiency, and grinding contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

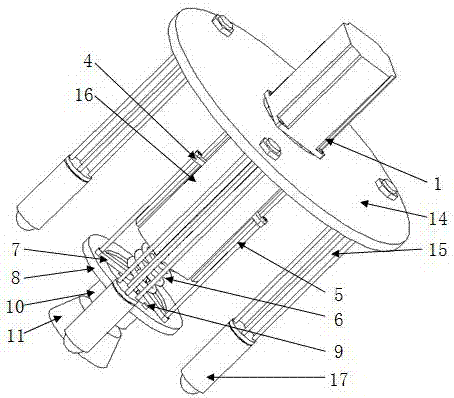

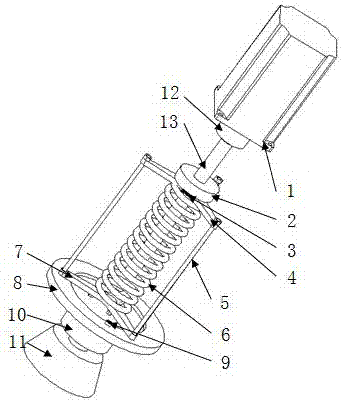

[0020] A kind of large-scale curved surface grinding self-adaptive grinding device designed by the present invention (abbreviation device, see figure 1 ), including surface adaptive moving mechanism and force-controlled grinding tool module.

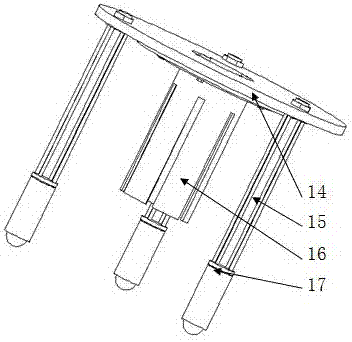

[0021] The curved surface adaptive moving mechanism includes a top plate 14, a cylindrical slot 16, a support rod 15 and a universal wheel 17; wherein the top plate 14 is provided with a support rod 15 assembly hole, a top motor 1 assembly hole, and a cylindrical clip slot 16 Assembling holes, the cylindrical card slot 16 is fixed on the top plate 14 by bolts, the number of support rods 15 and universal wheels 17 is three, and the two are evenly distributed on a 120° circumference, and one end of the support rod 15 and the universal wheels 17 pass through Thread fit connection, the other end of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com