Material conveying device

A material conveying and mixing technology, which is applied in the field of mixing and feeding devices, can solve problems such as unevenness, many manual operation steps, and non-continuous output, and achieve the effect of reducing equipment costs and increasing mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

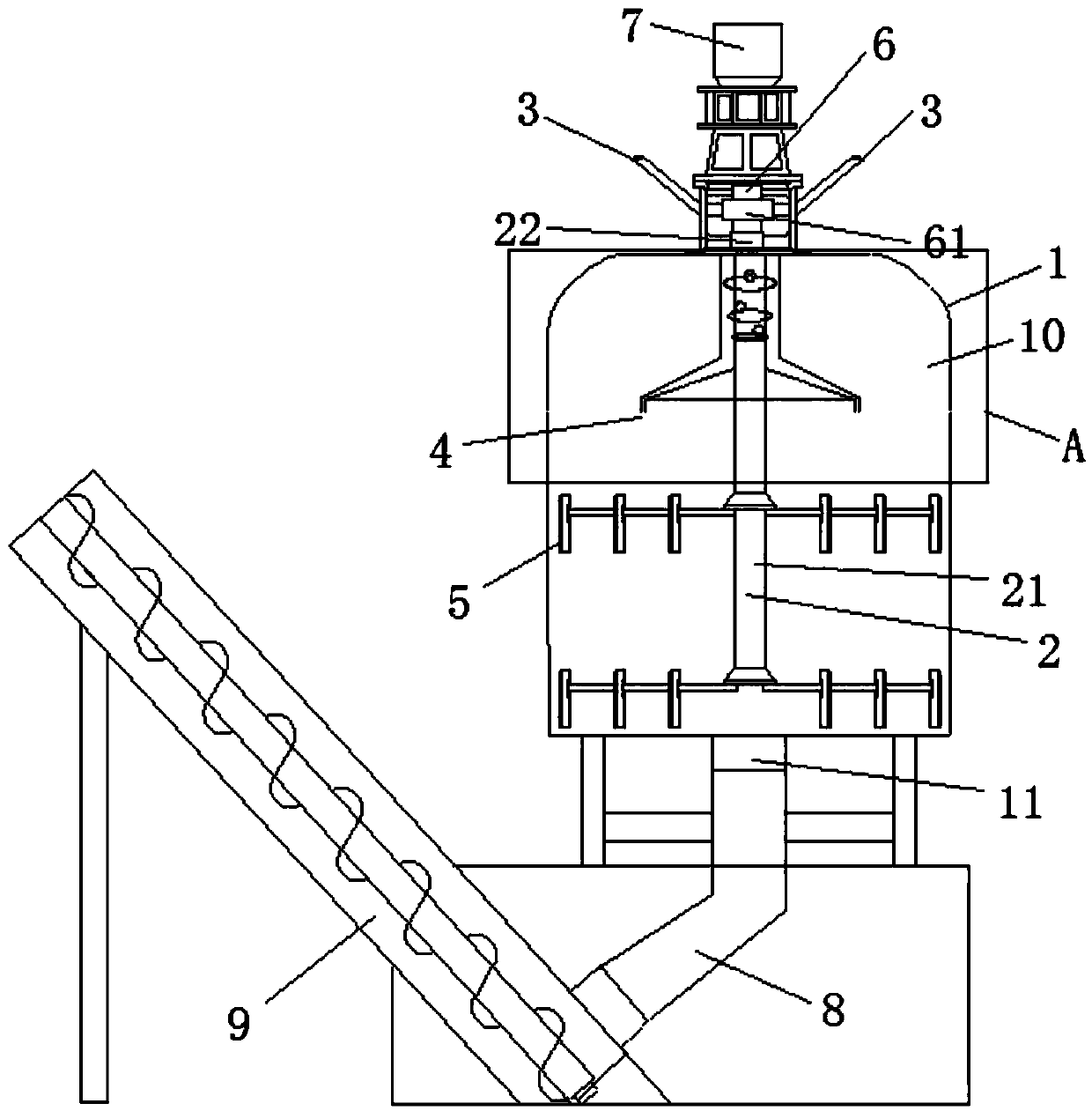

[0040] This embodiment provides a feeding device, such as Figure 1-3 shown, including:

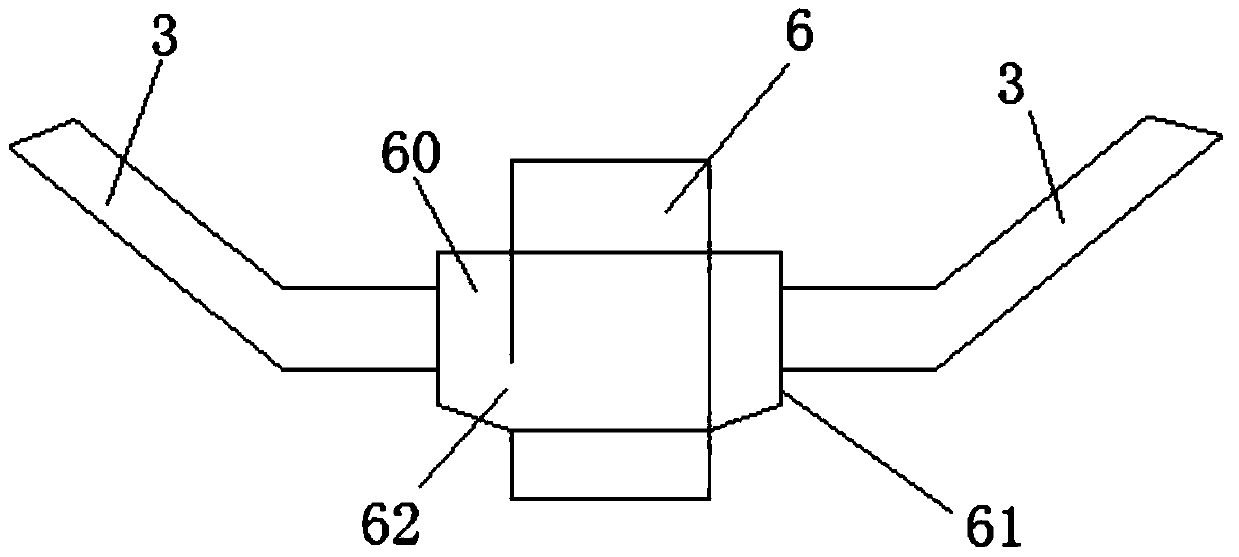

[0041] The connecting cylinder 6 has an inner cavity of the connecting cylinder;

[0042] The casing 61 is arranged around the connecting cylinder 6 and forms a material storage space 60 with the outer wall of the connecting cylinder 6, and the connecting cylinder 6 can rotate around the casing 61;

[0043] There are two feeding pipes 3, which are arranged on both sides of the housing 61 and communicate with the material holding space 60;

[0044] There are several feeding ports 62, which are evenly arranged on the connecting cylinder 6, and communicate with the material holding space 60 and the inner cavity of the connecting cylinder;

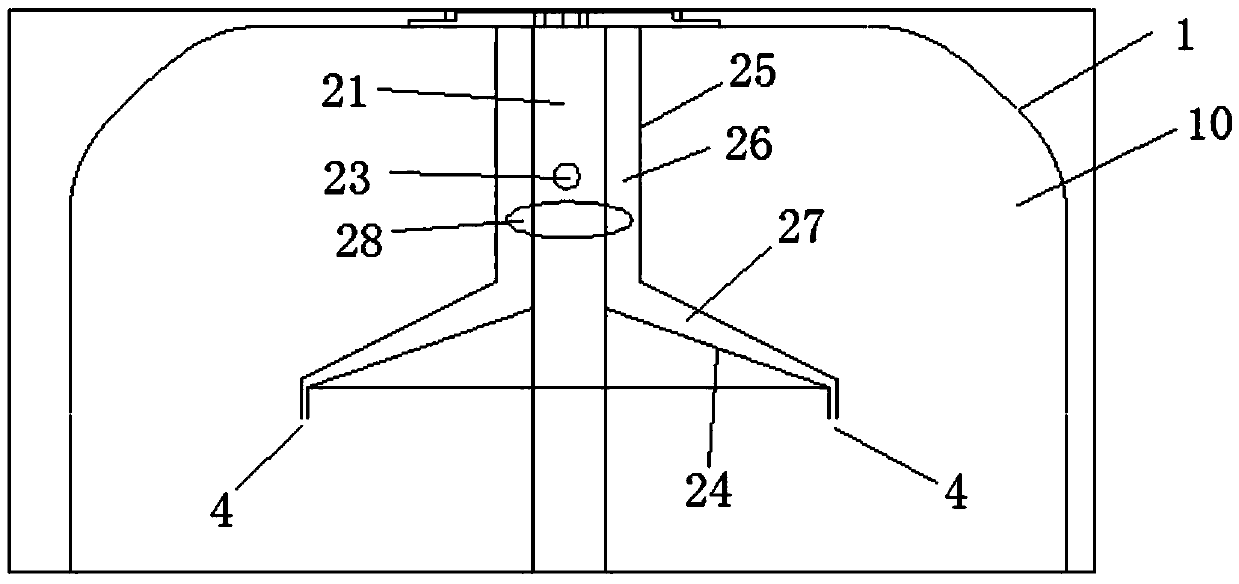

[0045] The drum 2 has a first segment 21 and a second segment 22, and a drum inner cavity is arranged inside, and the inner cavity of the drum communicates with the inner cavity of the connecting drum;

[0046] The stirring chamber 1 has a stirring space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com