Production method of acidic potassium thiophosphate

A kind of technology of acid potassium thiophosphate and production method, which is applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems such as no good industrial production method of acid potassium thiophosphate, achieve good market prospect, simple method, and solve Easy to absorb moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

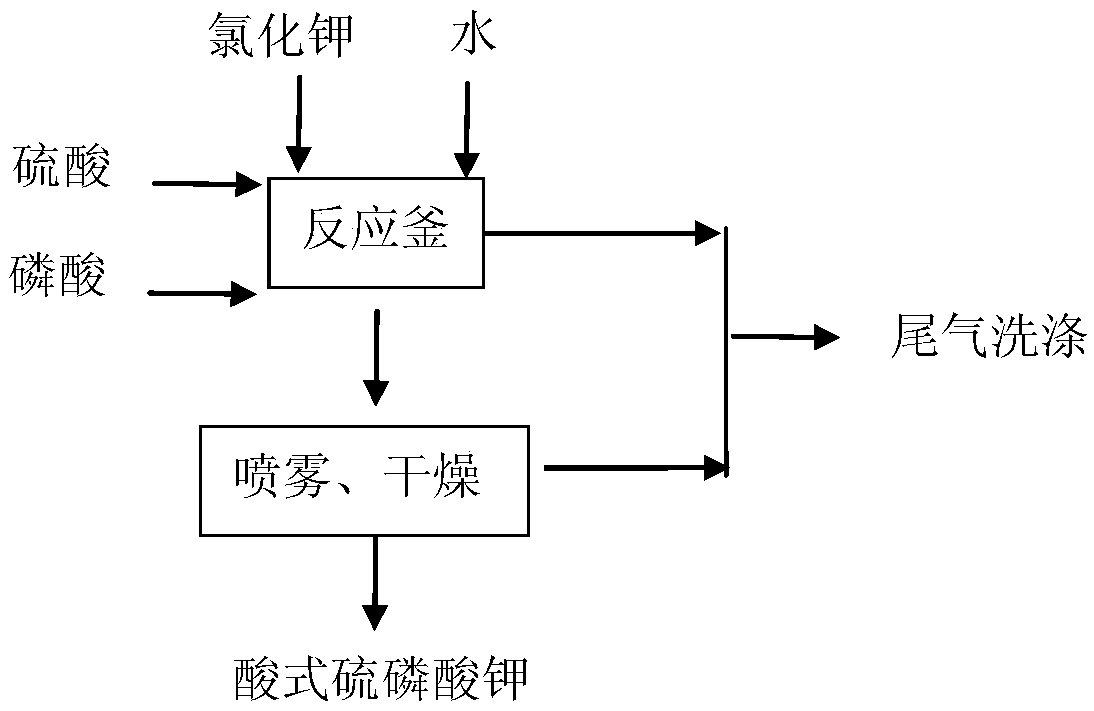

Method used

Image

Examples

Embodiment 1

[0042] Weigh 100kg of potassium chloride, add it to 60kg of water, start stirring, disperse evenly, heat to 60°C, and then follow the P 2 o 5 / K 2 O mass ratio is the ratio calculation of 1.0 Take wet-process phosphoric acid 149kg, join in the potassium chloride slurry that stirs, then according to H 2 SO 4 / K 2 O mol ratio is that the ratio calculation of 0.86 takes by weighing the concentrated sulfuric acid 69.2kg, reacts 3 hours;

[0043] Add the slurry to the dryer for atomization and drying, control the inlet temperature of the dryer to 230-270°C, and the outlet temperature to 110-130°C to obtain a powdery final product. Product indicators are shown in Table 4.

Embodiment 2

[0045] Weigh 100kg of potassium chloride, add it to 70kg of water, start stirring, disperse evenly, heat to 90°C, and then follow the P 2 o 5 / K 2 O mass ratio is that the ratio calculation of 1.2 takes wet-process phosphoric acid 179kg, joins in the potassium chloride slurry that stirs, then according to H 2 SO 4 / K 2 O molar ratio is that the ratio calculation of 0.5 takes by weighing the vitriol oil 40kg, reacts 2 hours;

[0046] Put the slurry into the dryer for atomization and drying, control the inlet temperature of the dryer to 280-300°C, and the outlet temperature to 100-110°C to obtain a powdery final product. Product indicators are shown in Table 4.

Embodiment 3

[0048] Weigh 100kg of potassium chloride, add it to 90kg of water, start stirring, disperse evenly, heat to 80°C, and then follow the P 2 o 5 / K 2 O mass ratio is the ratio calculation of 0.8 Take wet-process phosphoric acid 119kg, join in the potassium chloride slurry that stirs, then according to H 2 SO 4 / K 2 O molar ratio is that the ratio calculation of 0.7 takes by weighing the vitriol oil 56kg, reacts 4 hours;

[0049] Add the slurry to the dryer for atomization and drying, control the inlet temperature of the dryer to 320-350°C, and the outlet temperature to 90-100°C to obtain a powdery final product. Product indicators are shown in Table 4.

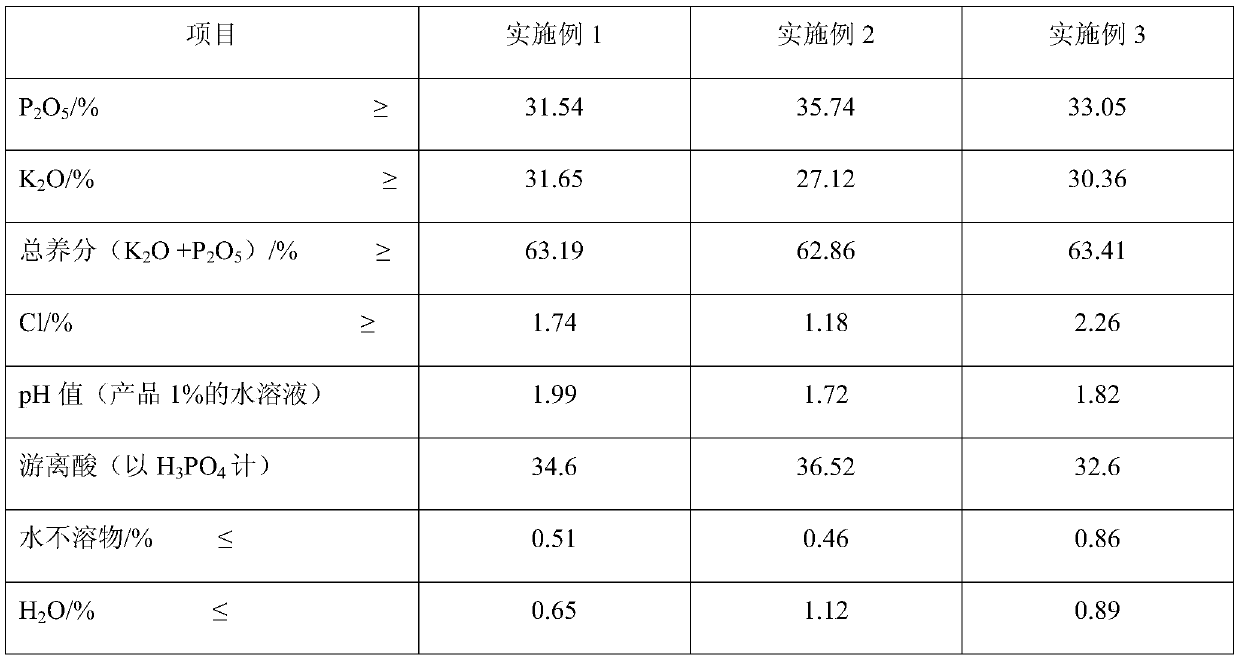

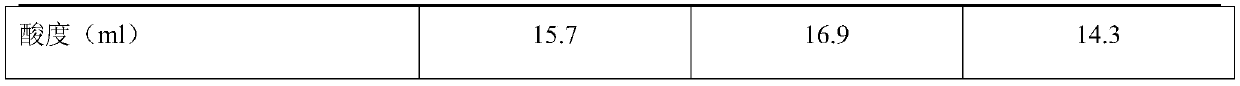

[0050] Table 2 Product Index

[0051]

[0052]

[0053] The method for measuring the acidity is: take 1 g of the sample, dissolve it in 100 ml of water, titrate it with 0.5 mol / L NaOH solution to a pH value of 6.5, and the volume of lye consumed is the acidity of the product. This can more intuitively reflect the abi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com