Preparation method of concrete water evaporation inhibitor

An evaporation inhibitor and concrete technology, applied in the field of concrete, can solve problems such as foaming, waste of transportation resources, and easy agglomeration of long-chain alcohols

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

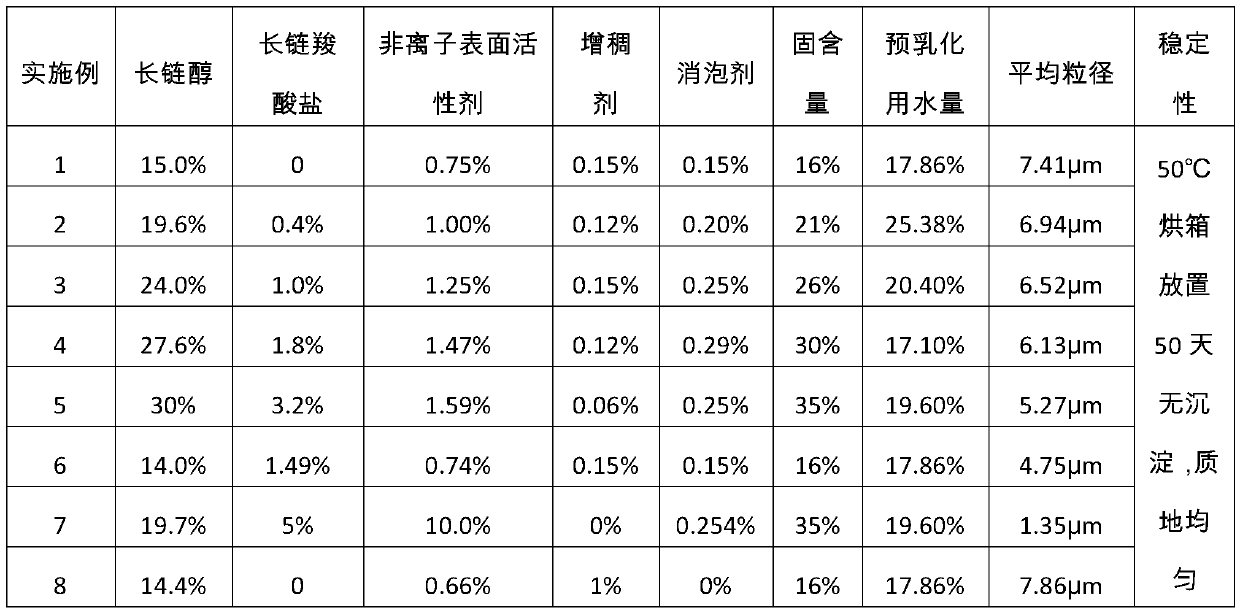

Embodiment 1

[0038]Heat 50g of straight-chain pentadecyl alcohol to 50°C to melt, add 2.5g of nonionic surfactant Pingping plus 20, 50g of water at 50°C to form an aqueous dispersion, shear at 1500r / min for 20min, and then quickly add 230g of 25°C Stir with water for 10 minutes, continue to add 0.5g of hydroxyethyl cellulose thickener and 0.5g of mineral oil defoamer to obtain a high-solid content concrete moisture evaporation inhibitor. Its solid content is 16%, and the emulsion is diluted 48 times and sprayed on the concrete surface. Compared with blank concrete, the 1h water evaporation inhibition rate is 68%, and the 4h water evaporation inhibition rate is 32%.

Embodiment 2

[0040] Heat 49g of straight-chain cetyl alcohol to 60°C to melt, add 1g of sodium cetadecanoate, 2.5g of nonionic surfactant Tween 60, and 50g of water at 60°C to form an aqueous dispersion, and shear at 2000r / min for 10min. Then quickly add 147g of water at 5°C and stir for 10 minutes, and continue to add 0.3g of hydroxyethyl cellulose thickener and 0.5g of mineral oil defoamer to obtain a high-solid content concrete moisture evaporation inhibitor. Tested that its solid content is 21%, diluted 64 times and sprayed on the concrete surface, compared with the blank concrete not sprayed with water evaporation inhibitor, the 1h water evaporation inhibition rate was 70%, and the 4h water evaporation inhibition rate was 35%.

Embodiment 3

[0042] Heat 48g of straight-chain heptadecanol to 70°C to melt, add 2g of potassium hexadecanoate, 2.5g of nonionic surfactant castor oil polyoxyethylene ether EL-40, and 30g of water at 70°C to form an aqueous dispersion, 2500r / Min high-speed shearing for 10 minutes, then quickly add 117g of 15°C water and stir for 10 minutes, continue to add 0.3g of polyacrylamide thickener and 0.5g of mineral oil defoamer to obtain a high-solid content concrete moisture evaporation inhibitor. Tested that its solid content is 26%, diluted 80 times and sprayed on the concrete surface, compared with the blank concrete not sprayed with water evaporation inhibitor, the 1h water evaporation inhibition rate was 68%, and the 4h water evaporation inhibition rate was 33%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com