Rigid foam flame-retardant polyether polyol and preparation method thereof

A flame retardant polyether and polyol technology, applied in the field of chemical synthesis, can solve problems such as performance impact, and achieve the effects of good durability of flame retardant performance and good physical performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

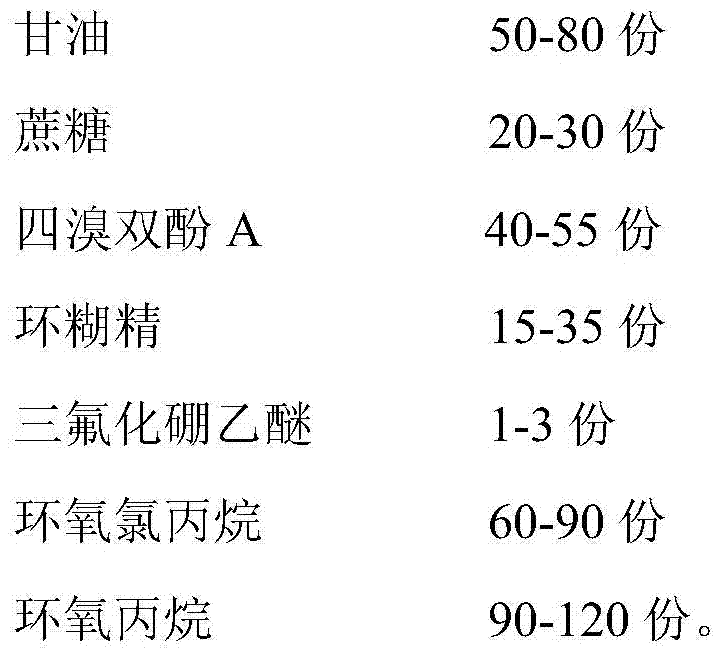

Method used

Image

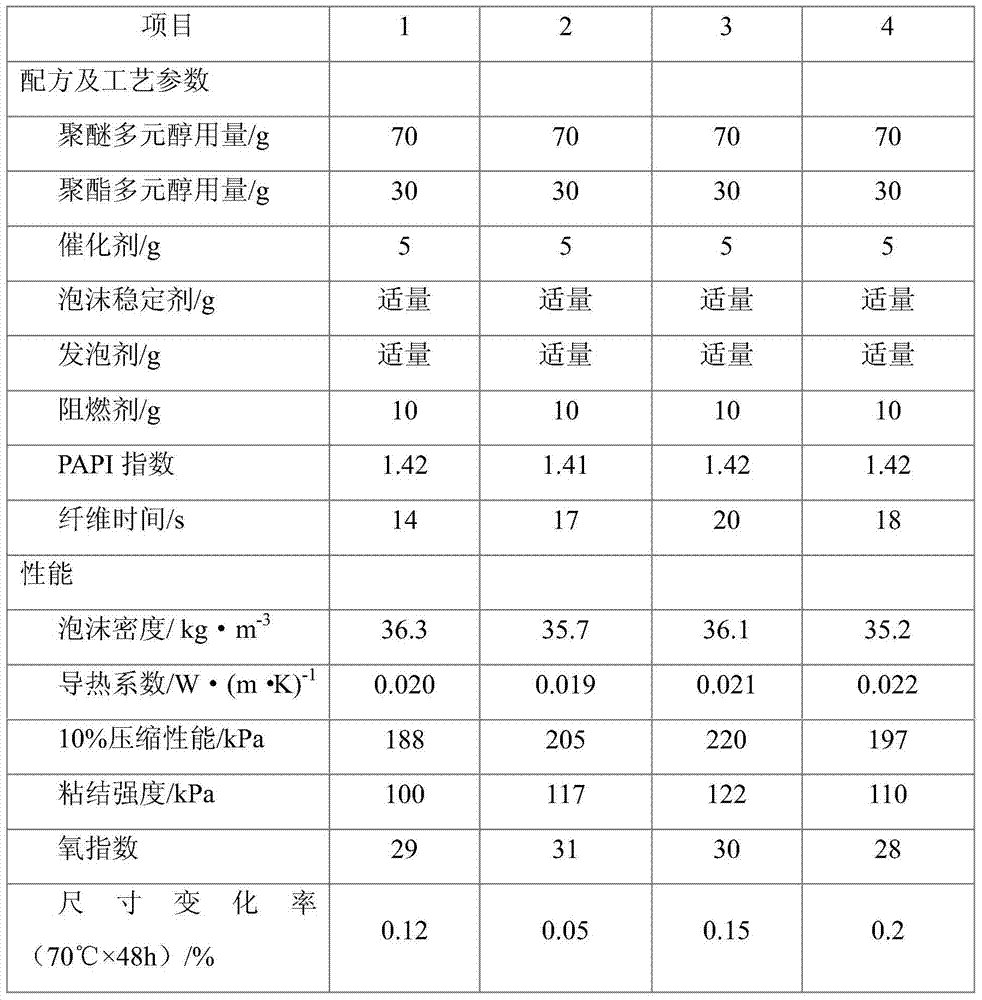

Examples

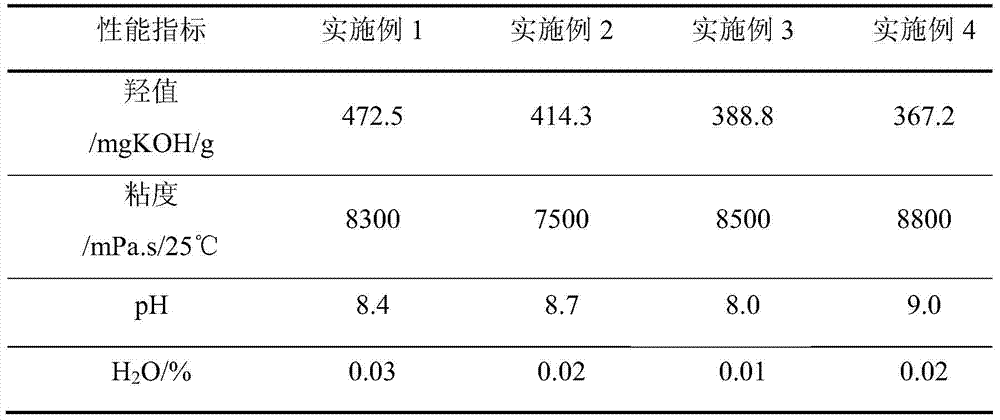

Embodiment 1

[0028] Add 80 parts of glycerin, 30 parts of sucrose, 50 parts of tetrabromobisphenol A, 15 parts of cyclodextrin into the stainless steel reaction kettle, and then add 2.5 parts of boron trifluoride ether, the temperature is ≤40°C; start stirring, nitrogen replacement twice ; Heating up to 100°C, stirring for 3 hours; then raising the temperature to 105°C, starting to continuously add 90 parts of epichlorohydrin and 90 parts of propylene oxide, controlling the pressure at 0.1-0.4MPa, the temperature at 110-115°C, and reacting for 6 hours under internal pressure to obtain product.

Embodiment 2

[0030] Add 50 parts of glycerin, 20 parts of sucrose, 55 parts of tetrabromobisphenol A, 25 parts of cyclodextrin into the stainless steel reaction kettle, and then add 3 parts of boron trifluoride ether, the temperature is ≤40°C; start stirring, nitrogen replacement 3 times ;Raise the temperature to 95°C and stir for 2.5h; then raise the temperature to 105°C, start adding 75 parts of epichlorohydrin and 120 parts of propylene oxide continuously, control the pressure at 0.1-0.4MPa, temperature at 105-110°C, and react for 4.5 hours under internal pressure , get the product.

Embodiment 3

[0032] Add 65 parts of glycerin, 25 parts of sucrose, 45 parts of tetrabromobisphenol A, 35 parts of cyclodextrin into the stainless steel reaction kettle, and then add 2 parts of boron trifluoride ether, the temperature is ≤40°C; start stirring, nitrogen replacement twice ; heat up to 80°C, stir for 2 hours; then heat up to 105°C, start to continuously add 60 parts of epichlorohydrin, 100 parts of propylene oxide, control the pressure 0.1-0.4MPa, temperature 105-110°C, internal pressure reaction 4h, get product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com