High-reflectivity polypropylene film and preparation method thereof

A technology of polypropylene film and high reflectivity, which is applied in the field of polypropylene film and its preparation, can solve the problems of uniform dispersion of uniformly plasticized active ingredients, difficulty in powder dispersion, difficulty in making films, etc., to achieve reflectivity improvement, The effect of increasing the overall reflectivity and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

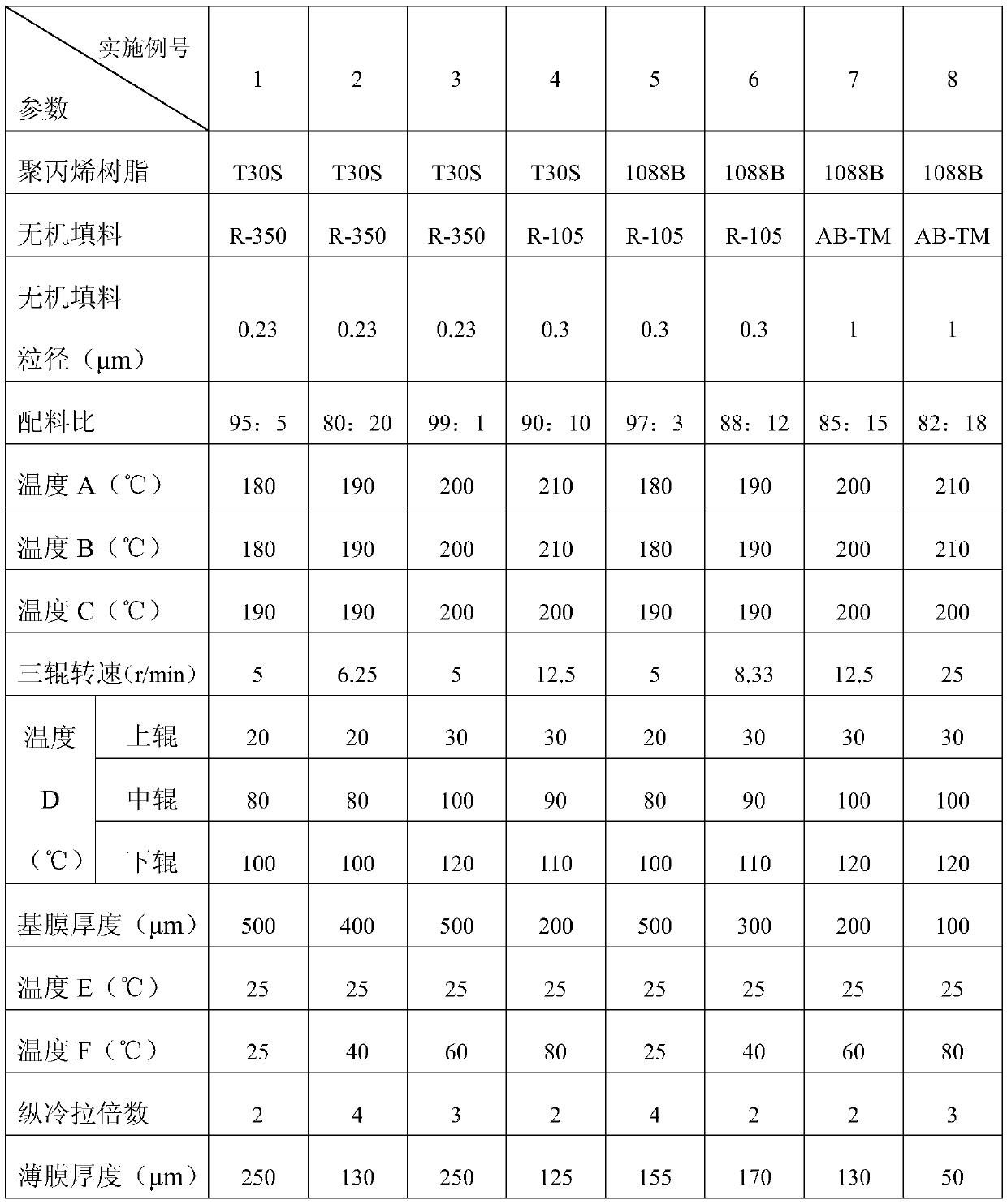

Embodiment 1~8

[0023] A preparation method of a high-reflectivity polypropylene film, the basic process is:

[0024] Polypropylene resin: inorganic filler = 99-80: 1-20 mass ratio of mixed ingredients, through a twin-screw extruder at 180-210 ° C (temperature A) blending extrusion granulation to make intermediate material for later use; The intermediate material is melted in the temperature range of 180-210°C (temperature B) by a single-screw extruder, extruded through a die head with a temperature of 190-200°C (temperature C), and passed through the roller temperature ( The temperature D) is 20-30°C for the upper roll, 80-100°C for the middle roll, and 100-120°C for the lower roll. The three diameters are 450mm and the speed is 2-25r / min. It is a polypropylene base film of 100-500 μm. After the polypropylene base film is cooled to 25°C (temperature E), it is then stretched longitudinally at a stretch ratio of 2 to 4 times at 25°C-80°C (temperature F). Longitudinal cold drawing), that is, a...

Embodiment 9

[0033] A high reflectivity polypropylene film, the high reflectivity polypropylene film is a film material composed of polypropylene resin and inorganic filler, the mass ratio of the polypropylene resin and the inorganic filler in the film material is 99: 1;

[0034]The high-reflectivity polypropylene film is obtained by blending, extruding, and granulating a mixture of raw materials with a mass ratio of polypropylene resin: inorganic filler = 99:1 through a twin-screw extruder at a temperature of 180°C to make an intermediate material; The intermediate material is melted at a temperature of 180°C by a single-screw extruder, extruded through a die head with a temperature of 190°C, and passed through an upper roll with a temperature of 20°C, a middle roll with a temperature of 80°C, and a lower roll with a temperature of 100°C. The polypropylene base film with a thickness of 100 μm is salivated on three rollers with a diameter of 450 mm and a rotation speed of 2 to 25 r / min. Af...

Embodiment 10

[0036] A high reflectivity polypropylene film, the high reflectivity polypropylene film is a film material composed of polypropylene resin and inorganic filler, the mass ratio of the polypropylene resin and the inorganic filler in the film material is 80: 20;

[0037] The high-reflectivity polypropylene film is obtained by blending, extruding, and granulating a mixture of raw materials with a mass ratio of polypropylene resin: inorganic filler = 80:20 by a twin-screw extruder at a temperature of 210°C to make an intermediate material; The intermediate material is melted at a temperature of 210°C by a single-screw extruder, extruded through a die head with a temperature of 200°C, and passed through an upper roll at a temperature of 30°C, a middle roll at 100°C, and a lower roll at 120°C in sequence by drooling. The polypropylene base film with a thickness of 500 μm is salivated on three rollers with a diameter of 450 mm and a rotation speed of 2 to 25 r / min. After the polypropy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com