High-impact lusterless modified reclaimed PP (polypropylene) material and preparation method thereof

A high-impact, recycled material technology, applied in the high-impact field, can solve problems that do not involve the mechanical properties of recycled PP, and achieve the effect of matte surface, high impact, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

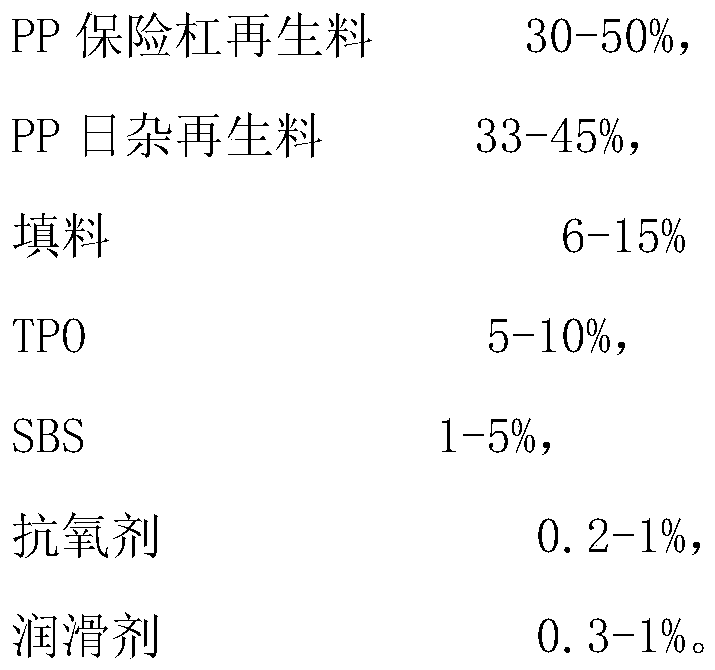

[0024] A high impact, matte modified recycled PP material comprising the following components by weight:

[0025]

[0026]

[0027] Above-mentioned a kind of high impact, the preparation method of the modified regenerated PP material of dullness, comprises the following steps:

[0028] (1) take each raw material by weight ratio;

[0029] (2) Put PP bumper recycled materials, PP daily miscellaneous recycled materials, fillers, TPO, SBS, lubricants, antioxidants into a high-speed mixer and mix evenly, and discharge;

[0030] (3) Put the raw materials mixed in step (2) into a twin-screw extruder to extrude and granulate. The main engine speed of the twin-screw machine is 25-32Hz, the feeding frequency is 8Hz, and the barrel temperature is 220-230°C , through twin-screw extruder fully plasticized, melted, compounded, head extruded and cooled.

Embodiment 2

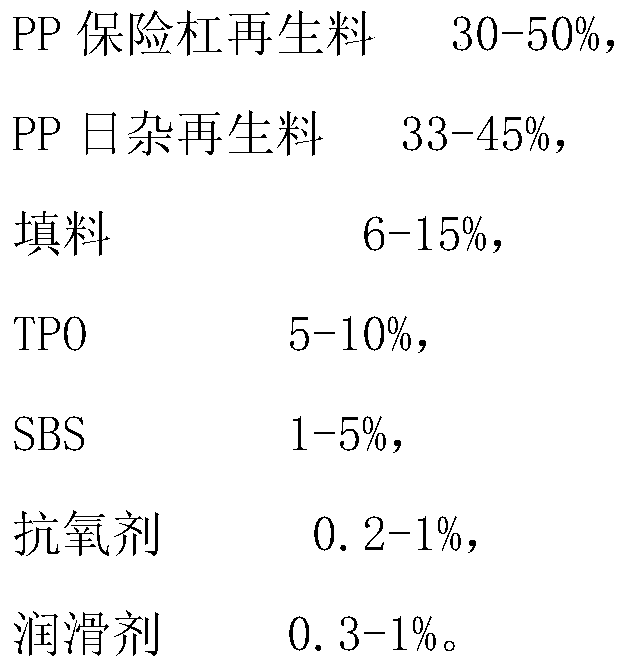

[0032] A high impact, matte modified recycled PP material comprising the following components by weight:

[0033]

[0034] The preparation method of the above-mentioned modified recycled PP material is the same as that in Example 1.

Embodiment 3

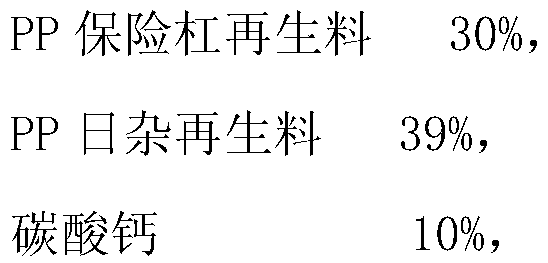

[0036] A high impact, matte modified recycled PP material comprising the following components by weight:

[0037]

[0038]

[0039] The preparation method of the above-mentioned modified recycled PP material is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com