Water-based drilling fluid for low-temperature formation drilling

A drilling fluid and water-based technology, which is applied in the field of water-based drilling fluid and low-temperature formation drilling water-based drilling fluid, can solve the problems of comprehensive performance such as wellbore stability and hydrate inhibitory filtration performance, etc., and achieve good The effects of wellbore stability, good hydrate inhibition, and good fluid loss wall building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

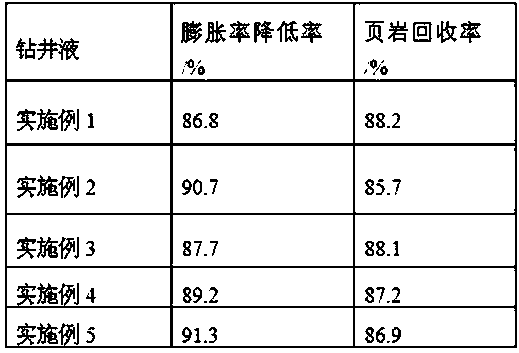

Examples

Embodiment 1

[0022] Embodiment 1: preparation of seawater-based deep-water drilling fluid system, including the following components by weight:

[0023] 3kg of sodium-based bentonite is used for slurry preparation; 3kg of polyethylene glycol and 5kg of KCl are used for shale inhibitor; 0.2kg of xanthan gum and 0.5kg of viscoelastic surfactant cetyltrimethylammonium chloride are used as flow regulator The coating inhibitor uses cationic polyacrylamide 0.1kg; the fluid loss reducer uses polyanionic cellulose and starch, among which: polyanionic cellulose 0.5kg; starch 2.5kg; the lubricant uses vegetable oil ester lubricant SD-505: 1kg; hydrate inhibitor using NaCl: 10kg; seawater is recorded as 100kg.

Embodiment 2

[0025] Prepare the clay-free seawater-based deepwater drilling fluid system, including the following components by weight percentage:

[0026] Sodium bentonite 0kg is used for slurry preparation; shale inhibitor is polyethylene glycol 3kg; coating inhibitor is partially hydrolyzed polyacrylamide 0.2kg; flow regulator is xanthan gum 0.4kg; Anionic cellulose 0.5kg; starch 1.5kg; sulfonated phenolic resin 4kg; hydrate inhibitor using NaCl: 20kg; mineral oil 2kg; barite 20kg; seawater is recorded as 100kg.

Embodiment 3

[0027] Embodiment 3: preparation of seawater-based deep-water drilling fluid system, including the following components by weight:

[0028] Calcium-based bentonite 4kg is used for slurry preparation; polyethylene glycol 0.3kg and potassium chloride 0.7kg are used as shale inhibitor; xanthan gum 2kg and viscoelastic surfactant cetyl trimethyl chloride are used as flow regulator Ammonium chloride 3kg; cationic polyacrylamide 0.5kg used as coating inhibitor; polyanionic cellulose and starch used as fluid loss control agent, among which: polyanionic cellulose 3kg; starch 7kg; lubricant used vegetable oil ester lubricant SD-505 : 1kg; hydrate inhibitor using NaCl: 40kg; seawater is recorded as 100kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com