Device for recovering zinc by using zinc-contained dust of steel and iron works and recovery method thereof

A technology for dust recovery and iron and steel plants, applied in the direction of recycling technology, process efficiency improvement, etc., can solve problems such as complex process, pollution, and ineffective effects, and achieve the effect of expanding the range of raw materials, saving coke, and increasing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

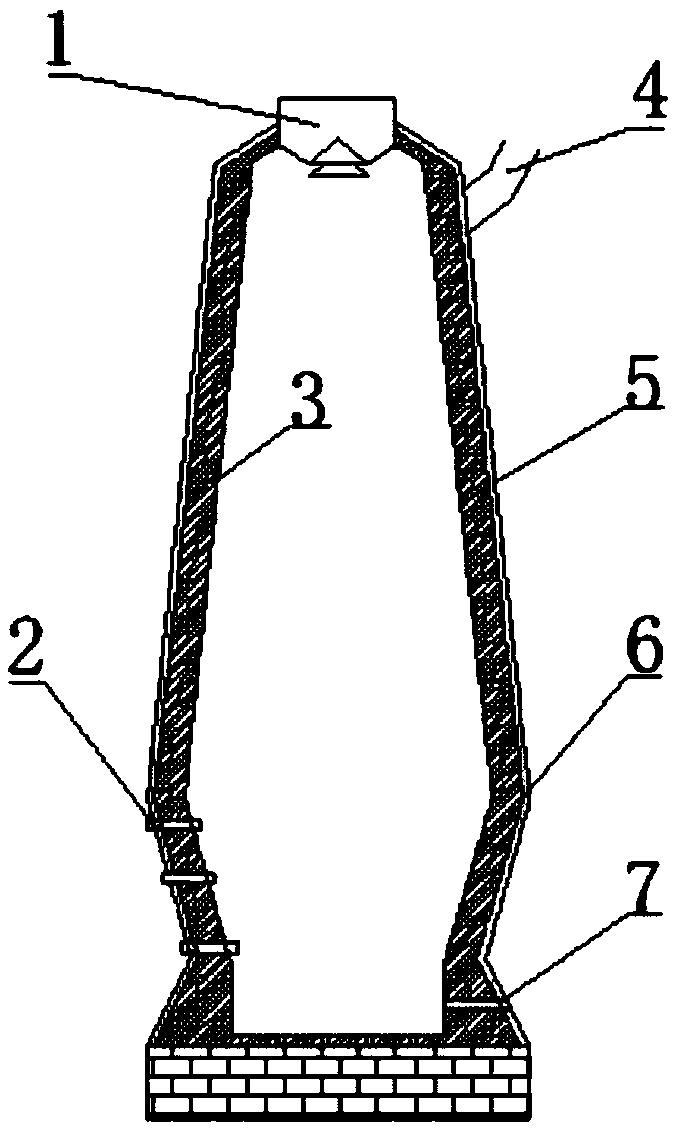

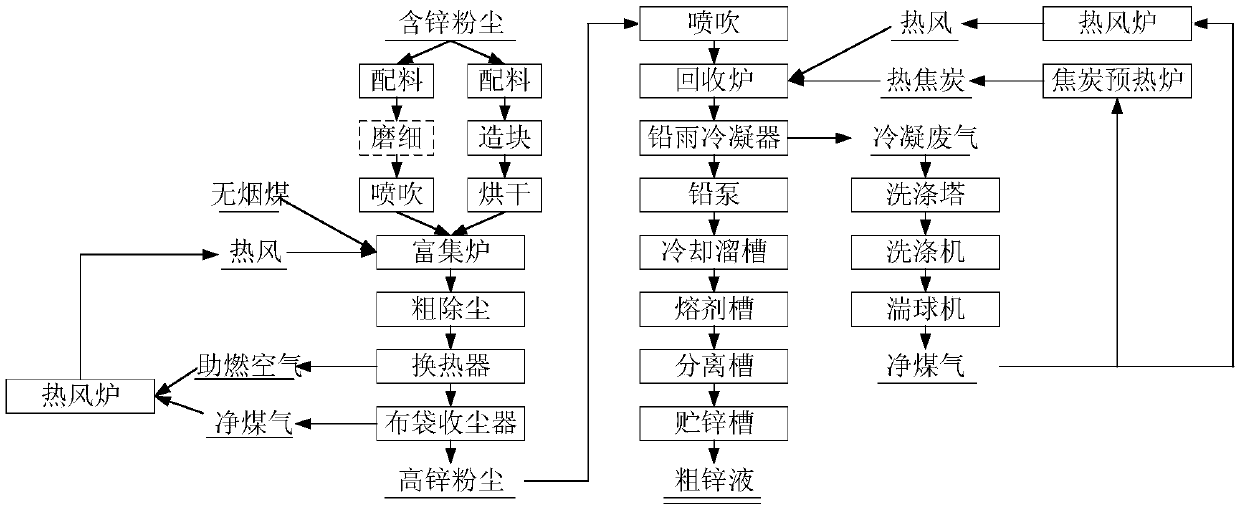

[0025] [Example 1] A device for recovering zinc from iron and steel plant zinc-containing dust. The zinc recovery device includes: a blowing device, a hot blast stove, an enrichment furnace device, a recovery furnace device, and a high-zinc flue gas separation device. The collection furnace device, the recovery furnace device and the high-zinc flue gas separation device are connected in sequence, and the enrichment furnace device and the recovery furnace device are respectively connected with a blowing device and a hot blast stove.

[0026] The blowing device includes: a first batching bin, a second batching bin, a ball mill, a dust hopper, a blowing tank, a blowing pipeline, a mixer, a distributor and a spray gun. The spraying device adopts combined tank spraying, and the first batching bin and the second batching bin are arranged side by side, respectively containing agglomerated zinc-containing dust and zinc-containing dust that can be directly sprayed, and the agglomerated ...

Embodiment 2

[0034] [Example 2] This example is basically the same as the above example, the only difference is that the high-zinc flue gas separation device includes an oxidation separation device, and the oxidation separation device includes: a second coarse dust collector, a waste heat boiler, The second heat exchanger, spray scrubber, circulating pool, circulating pump, centrifugal dryer. The second coarse dust remover of the oxidation separation device is connected with the second flue of the recovery furnace, the second coarse dust remover, the waste heat boiler, the second heat exchanger, and the spray scrubber are connected in sequence, using a The rapping waste heat boiler prevents clogging. A circulating water pool is installed under the spray scrubber, a circulating water pump is installed in the circulating pool, a centrifugal dryer is installed next to the circulating pool, and a dehydrator is installed at the flue gas outlet of the spray scrubber.

[0035] After the high-zinc...

Embodiment 3

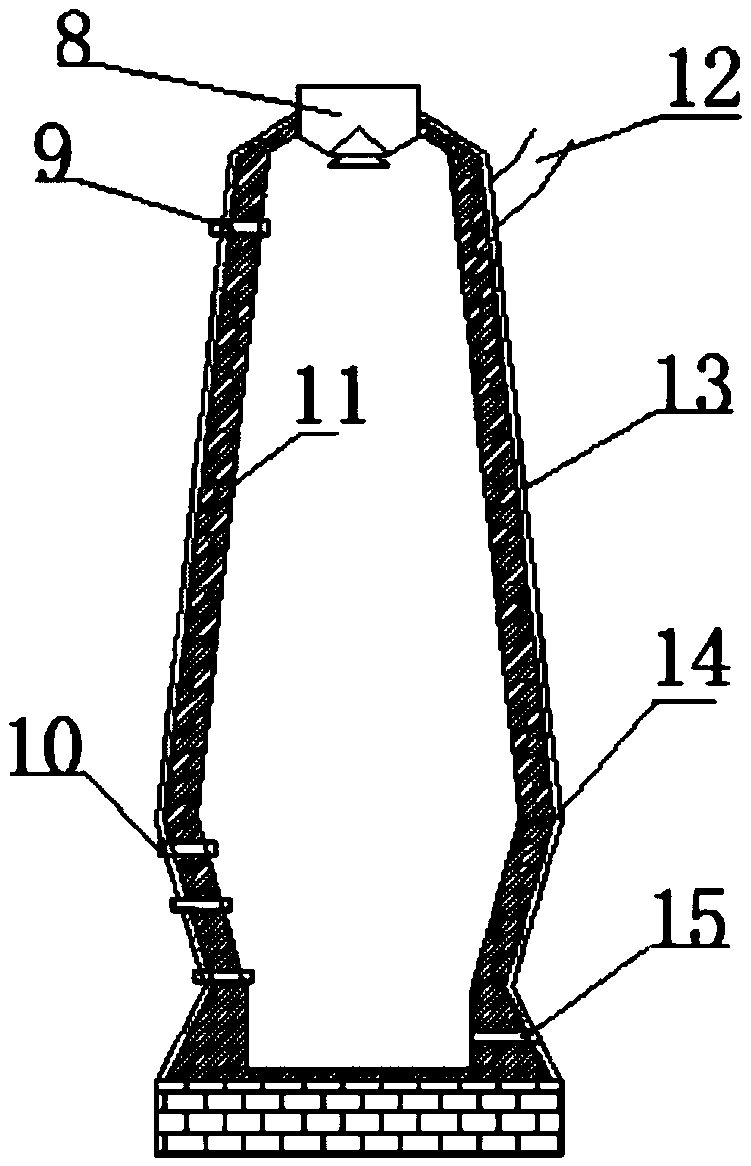

[0036] [Example 3] In this embodiment, the zinc recovery device includes: a blowing device, a hot blast stove, a recovery furnace device and a high-zinc flue gas separation device, and the recovery furnace device is respectively connected with the blowing device, the hot blast stove, the high The zinc fume separation device is connected, and the recovery furnace device includes: a recovery furnace and a coke preheating furnace, and the coke preheating furnace is arranged above the recovery furnace. The recovery furnace is connected with a blowing device and a hot blast stove. The recovery furnace includes: a second bell top charging device 8, a secondary tuyere 9, a second tuyere 10, a second flue 12, a second Two steel furnace shells 13, the second stave 14, the second refractory lining 11, the second iron hole 15, the second steel furnace shell 13, the second stave 14 and the second refractory lining 11 form a recovery furnace body, the lower part of the recovery furnace is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com