Nanometer Sn ball preparing method

A technology of nanometer and heat treatment equipment, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low operating safety, poor luminous performance, high experimental cost, etc., to achieve high safety, Good luminous performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] 1) Substrate cleaning:

[0024] A 1-inch glass substrate was washed by brush, ultrasonically cleaned in absolute ethanol for 10 minutes, and ultrasonically cleaned in pure water for 10 minutes, and then set aside. Brushing is mainly used to clean the particles on the surface of the substrate. Ultrasonic cleaning in absolute ethanol is mainly used to clean the organic matter on the surface of the substrate. Ultrasonic cleaning in pure water is used to clean the residual ethanol on the surface of the substrate. Cleaning is beneficial to the spreading of rosin on the glass surface. A uniform and smooth film can be obtained;

[0025] 2) Coating of rosin:

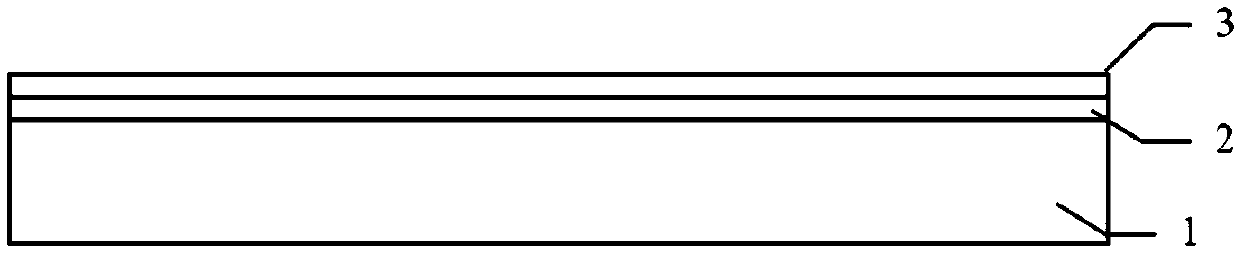

[0026] heating the rosin to soften it, and then coating a layer of rosin 2 on the surface of the glass substrate 1 with a thickness of 1 μm by printing;

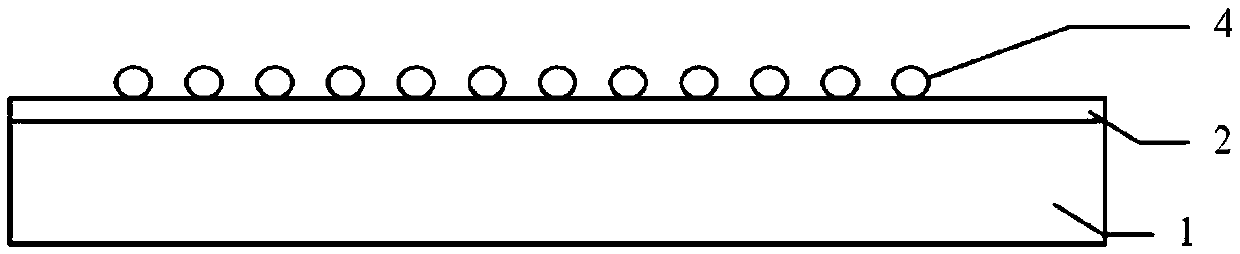

[0027] 3) Preparation of Sn film:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com