Organic light emitting diode, manufacturing method thereof, pixel structure and manufacturing method thereof

A technology of light-emitting diodes and organic light-emitting layers, which is applied in the field of pixel structure and its production, organic light-emitting diodes and its production, and can solve the problems that cannot be used to prepare organic light-emitting layers of RGB multi-color pixel arrays, uneven light emission of display pixels, and obstruction of space. Effective hole injection and other issues to achieve excellent luminous performance, high luminous uniformity, and low light-up voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

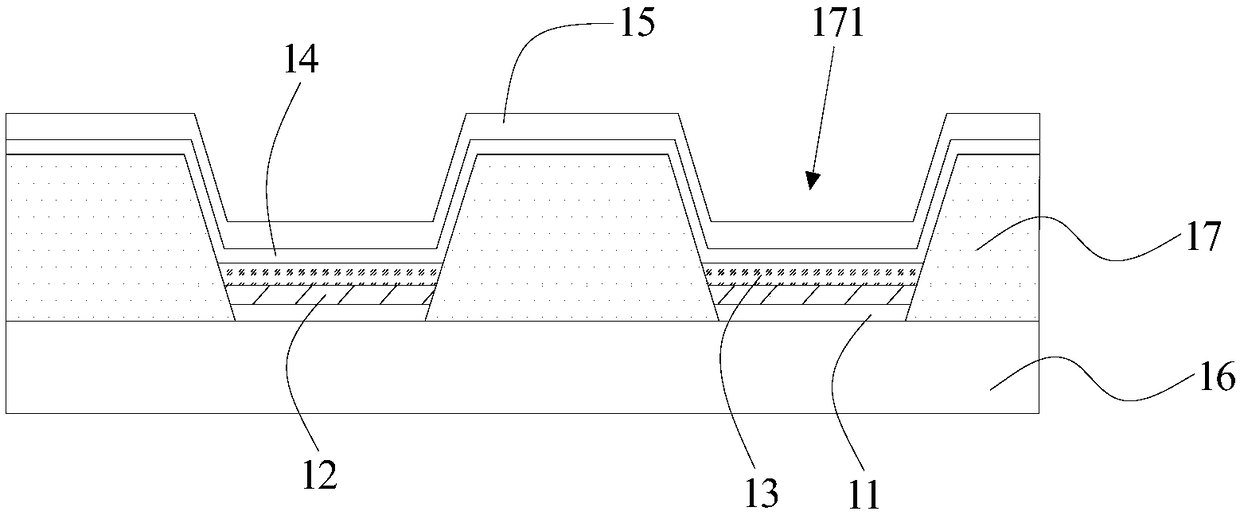

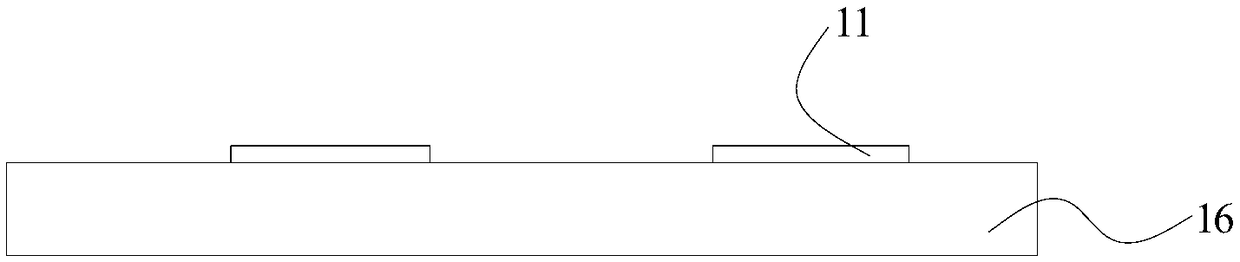

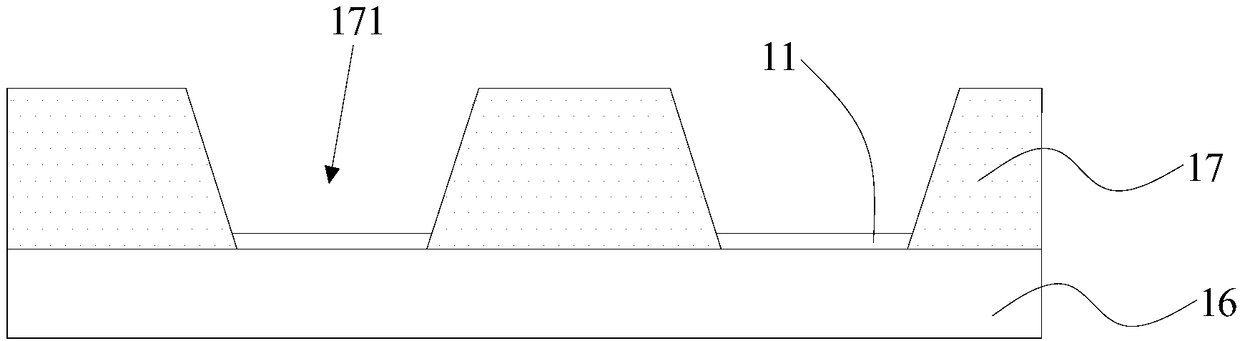

[0041] This embodiment provides an organic light emitting diode, specifically refer to figure 1 , according to the present embodiment, the organic light emitting diode comprises an anode 11, a hole injection layer 12, an organic light emitting layer 13, an electron transport layer 14 and a cathode 15 which are sequentially stacked; wherein, the work function of the material of the hole injection layer 12 is the same as The highest occupied orbital energy levels of the materials of the organic light emitting layer 13 are matched.

[0042] Specifically, the material of the organic light-emitting layer 13 is a polymer light-emitting material with the highest occupied orbital energy level of 5.5eV-6.2eV or an organic small molecule light-emitting material with a molecular weight of no more than 1000. Correspondingly, the material of the hole injection layer 12 The work function is controlled to be 5.5eV-6.0eV, which satisfies the matching between the two, so that excellent luminou...

Embodiment 2

[0064] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between Example 2 and Example 1 is that in the organic light-emitting diode of Example 2, the material of the organic light-emitting layer is preferably poly[2-(4-(3 ', 7'-dimethyloctyloxy)-phenyl)-p-phenylene vinylene] (referred to as P-PPV), and the material of the hole injection layer is PEDOT:PSS:PFI with a work function of about 5.95eV, And in the PEDOT:PSS:PFI, the mass ratio of the three monomers PEDOT, PSS, and PFI is 1:6:1.6. Apparently, the material of the organic light-emitting layer in this embodiment can emit green light.

[0065] In the manufacturing method of the organic light emitting diode in this embodiment, the difference from the manufacturing method of the organic light emitting diode in embodiment 1 is that in step S2, the three monomers PEDOT and PSS are printed on the anode...

Embodiment 3

[0068] In the description of Embodiment 3, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between embodiment 3 and embodiment 1 is that in the manufacturing process of the organic light emitting diode of this embodiment, in step S1, a flexible transparent conductive polyimide (referred to as PI) is used as the anode electrode substrate, one of which is On the one hand, it acts as a substrate, and on the other hand, it acts as a conductive anode; for the rest, refer to the manufacturing method described in Example 1 to obtain an organic light-emitting diode.

[0069] The maximum luminance of the organic light emitting diode obtained in this embodiment is 5000cd / m 2 ~5500cd / m 2 , the maximum current efficiency is 7cd / A, and the lighting voltage is 5V; the organic light emitting diode provided in this embodiment shows excellent luminous performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Work function | aaaaa | aaaaa |

| Work function | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com