A corrosion-resistant and anti-blocking PE composite sewage pipe

A sewage pipe and anti-blocking technology, applied in the field of sewage pipes, can solve the problems of affecting the service life of pipes, blockage or water leakage of pipes, rough and unequal pipe walls, and achieve easy flow of sewage, prolong service life, and improve hydrophobicity and resistance. Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

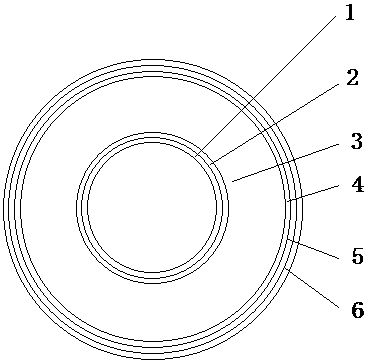

[0049] as attached figure 1 Shown:

[0050] A corrosion-resistant and anti-blocking PE composite sewage pipe, including a pipe body, the pipe body includes a PE layer 3 as a main body, a graphite layer 2 is provided inside the PE layer 3, and a hydrophobic corrosion-resistant pipe is provided inside the graphite layer 2. Layer 1, the outside of the PE layer 3 is provided with a reinforcement layer 4, the outside of the reinforcement layer 4 is provided with a PVDF layer 5, the outside of the PVDF layer 5 is provided with a wear-resistant layer 6, the inner wall of the pipe body is smooth, The outer wall of the pipe body is provided with spiral corrugations.

[0051] The hydrophobic corrosion-resistant layer 1 is a polytetrafluoroethylene layer, and the thickness of the hydrophobic corrosion-resistant layer 1 is 1.2 mm.

[0052] The thickness of the graphite layer 2 is 0.8mm.

[0053] The reinforcement layer 4 is carbon steel, and the thickness of the reinforcement layer 4 i...

Embodiment 2

[0079] as attached figure 1 Shown:

[0080] A corrosion-resistant and anti-blocking PE composite sewage pipe, including a pipe body, the pipe body includes a PE layer 3 as a main body, a graphite layer 2 is provided inside the PE layer 3, and a hydrophobic and corrosion-resistant pipe is provided inside the graphite layer 2. Layer 1, the outside of the PE layer 3 is provided with a reinforcement layer 4, the outside of the reinforcement layer 4 is provided with a PVDF layer 5, the outside of the PVDF layer 5 is provided with a wear-resistant layer 6, the inner wall of the pipe body is smooth, The outer wall of the pipe body is provided with spiral corrugations.

[0081] The hydrophobic corrosion-resistant layer 1 is a polytetrafluoroethylene layer, and the thickness of the hydrophobic corrosion-resistant layer 1 is 1.3mm.

[0082] The thickness of the graphite layer 2 is 1.0 mm.

[0083] The reinforcement layer 4 is carbon steel, and the thickness of the reinforcement layer...

Embodiment 3

[0109] as attached figure 1 Shown:

[0110] A corrosion-resistant and anti-blocking PE composite sewage pipe, including a pipe body, the pipe body includes a PE layer 3 as a main body, a graphite layer 2 is provided inside the PE layer 3, and a hydrophobic and corrosion-resistant pipe is provided inside the graphite layer 2. Layer 1, the outside of the PE layer 3 is provided with a reinforcement layer 4, the outside of the reinforcement layer 4 is provided with a PVDF layer 5, the outside of the PVDF layer 5 is provided with a wear-resistant layer 6, the inner wall of the pipe body is smooth, The outer wall of the pipe body is provided with spiral corrugations.

[0111] The hydrophobic corrosion-resistant layer 1 is a polytetrafluoroethylene layer, and the thickness of the hydrophobic corrosion-resistant layer 1 is 1.4mm.

[0112] The thickness of the graphite layer 2 is 1.2 mm.

[0113] The reinforcement layer 4 is carbon steel, and the thickness of the reinforcement layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com