Small weighing type continuous pulp flow weight concentration measurement device

A technology for concentration measurement and ore pulp, which is applied in the field of small weighing type continuous ore pulp flow weight concentration measurement device, which can solve the problems of valves, tube lewis jams, inability to realize online real-time detection very well, and poor real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

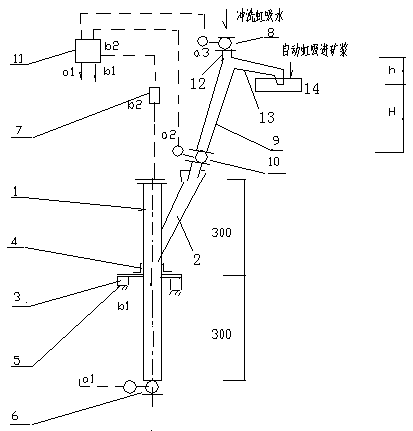

[0024] The invention measures the concentration of the ore pulp continuously flowing upwards and downwards. Sampling from the supernatant overflow pool of the spiral classifier or hydrocyclone after grinding in the concentrator can also be taken from other similar slurry process pools. The ore slurry flows through the measuring tube continuously from top to bottom, so the measuring device needs a natural height difference of about 1.5m, which is easy to meet in the concentrator. Carry out dynamic weighing and slurry level height measurement for small container tanks. When the dry ore density is basically unchanged, the amount of slurry entering and exiting is equal, and the level of slurry level in the tank remains unchanged, the weighed weight (excluding the weight of the tank body) ) to the pulp volume in the corresponding tank (the height of the pulp surface is measured accordingly) is the pulp density, and the pulp concentration is obtained by using the following formula (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com