Intelligent logistics optimization scheduling system

An intelligent optimization and scheduling system technology, applied in logistics, data processing applications, forecasting, etc., can solve the problems of transportation tool modification, manual intervention, and affecting OTD completion rate, so as to improve performance and avoid load imbalance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

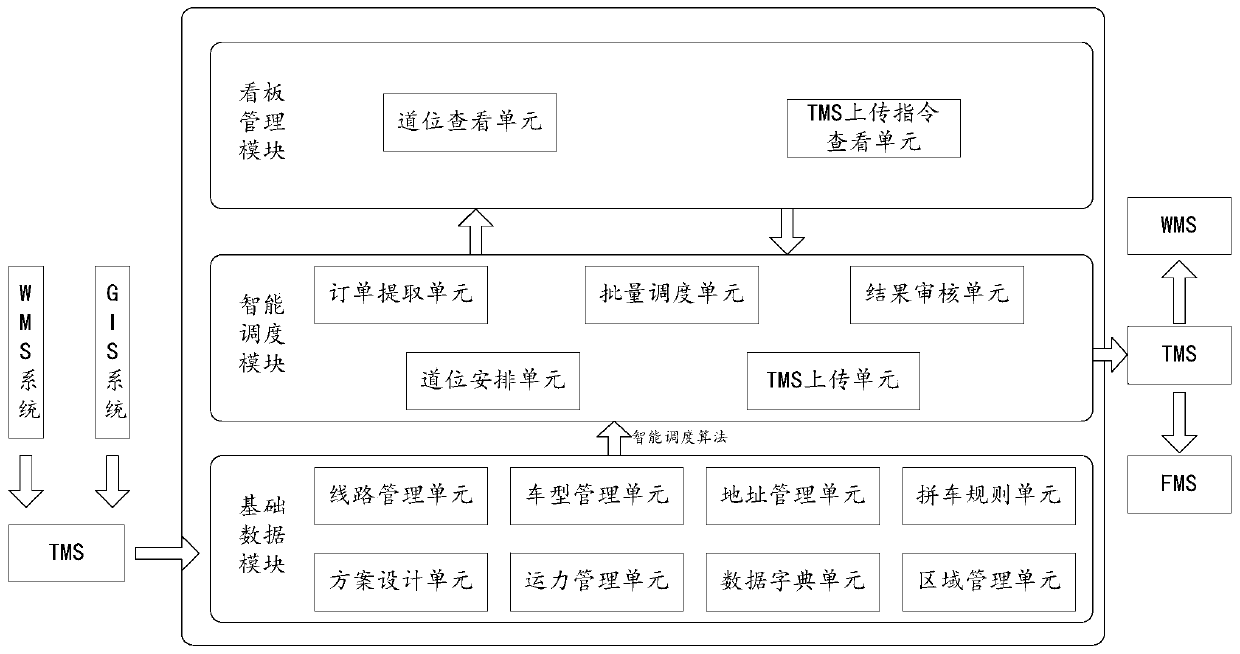

[0075] see figure 1 , the present invention discloses a logistics intelligent optimization scheduling system, said logistics intelligent optimization scheduling system includes: a basic data module, an intelligent scheduling module and a kanban management module.

[0076] 【Basic data module】

[0077] The basic data module is composed of eight parts: line management unit, vehicle type management unit, address management unit, carpooling rule unit, scheme design unit, capacity management unit, data dictionary unit, and area management unit.

[0078] The line is the basis for extracting orders, and is a very critical basic object of the entire intelligent dispatching system; the line management unit selects part of the field information in the basic route in the TMS to create a line for generating the dispatching system, and performs deletion, modification, and query operations, and at the same time realizes Multi-line merge function.

[0079] The vehicle type management unit d...

Embodiment 2

[0119] The intelligent scheduling system consists of three modules, namely basic data, intelligent scheduling and Kanban management. The basic data module includes the configuration of eight parts of basic information, such as line information, vehicle model information, address information, carpooling rules, scheme design, and capacity information; the intelligent dispatch module mainly realizes from order extraction to dispatch calculation, and conducts review according to the calculation results. Arrange lanes after success, and finally write back to TMS, a complete intelligent scheduling function; Kanban module management module includes lane check and TMS result query. The result query realizes the order information of the current scheduling status. The specific structure of the system is as figure 2 shown.

[0120] 2.1.1 Basic data module

[0121] The basic data module consists of eight parts: line management, vehicle type management, address management, carpooling r...

Embodiment 3

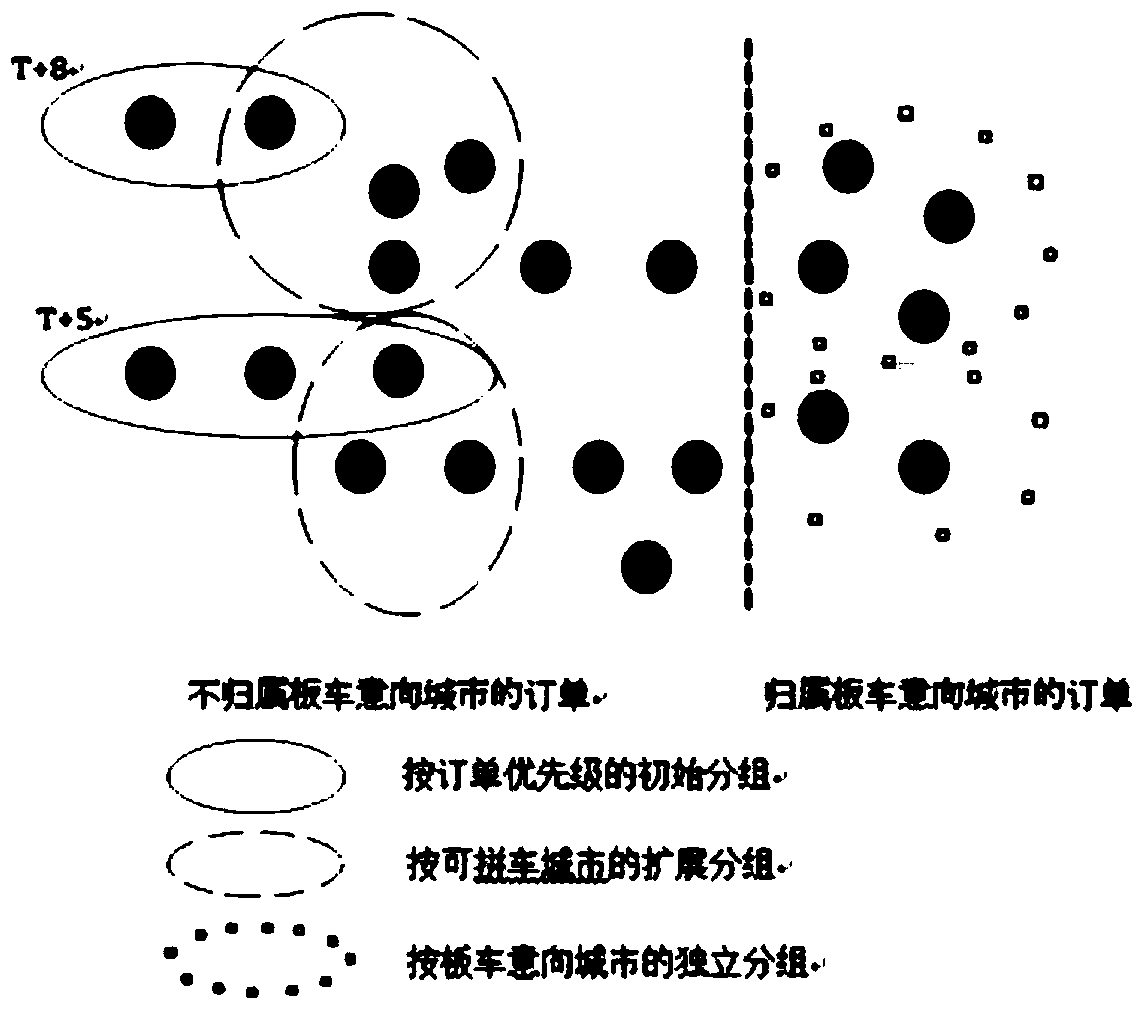

[0211] The difference between this embodiment and Embodiment 1 is that in this embodiment, the system includes an order grouping module. can refer to figure 2 , Different orders have different priorities according to their effective time, and when orders with different priorities are loaded, the number of carpooling cities and carpooling dealers that affect the results of pallet truck loading will also be quite different. For example, urgent orders can be assembled by multiple dealers in different places, while ordinary orders can only be assembled in the same city, and even require a single order to be full.

[0212] According to this feature, urgent orders (usually orders above t+3, parameters can be modified, t+3 refers to the order level) that can be assembled by multiple dealers and / or in different places can be grouped and calculated first, and the engine can relax the constraints and allow different places Carpooling, the emergency orders are assembled and shipped out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com