Quantum dot light-emitting diode sub-pixel array, manufacturing method thereof and display device

A quantum dot light-emitting and sub-pixel technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as high technical difficulty, high commodity prices, and low product yield, and achieve improved process yield and cost. The effect of reducing and facilitating the preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

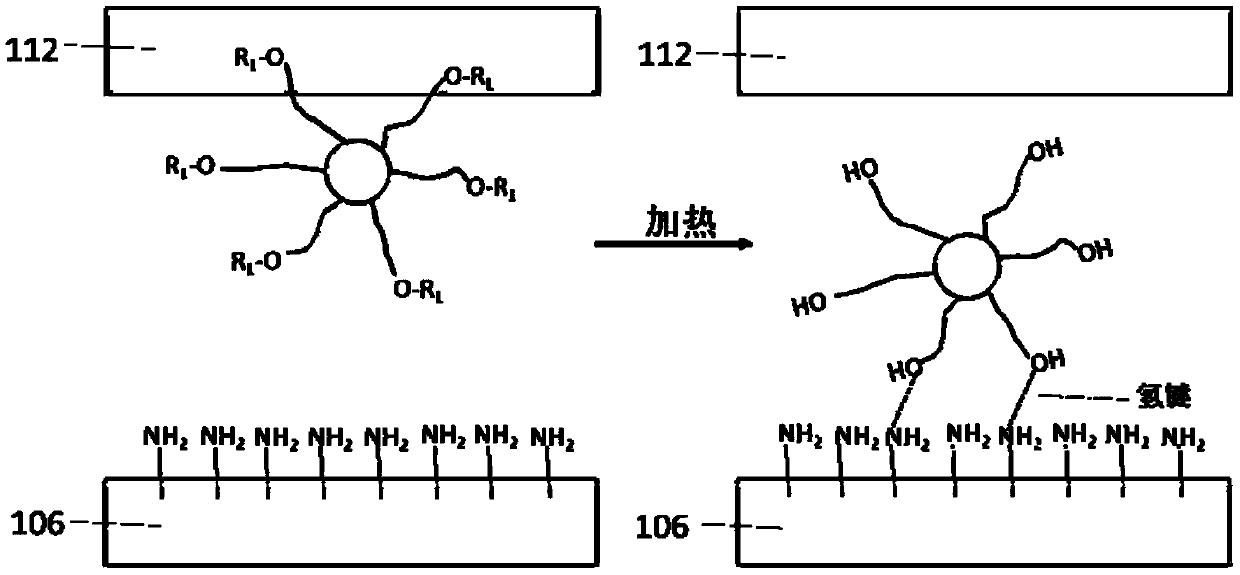

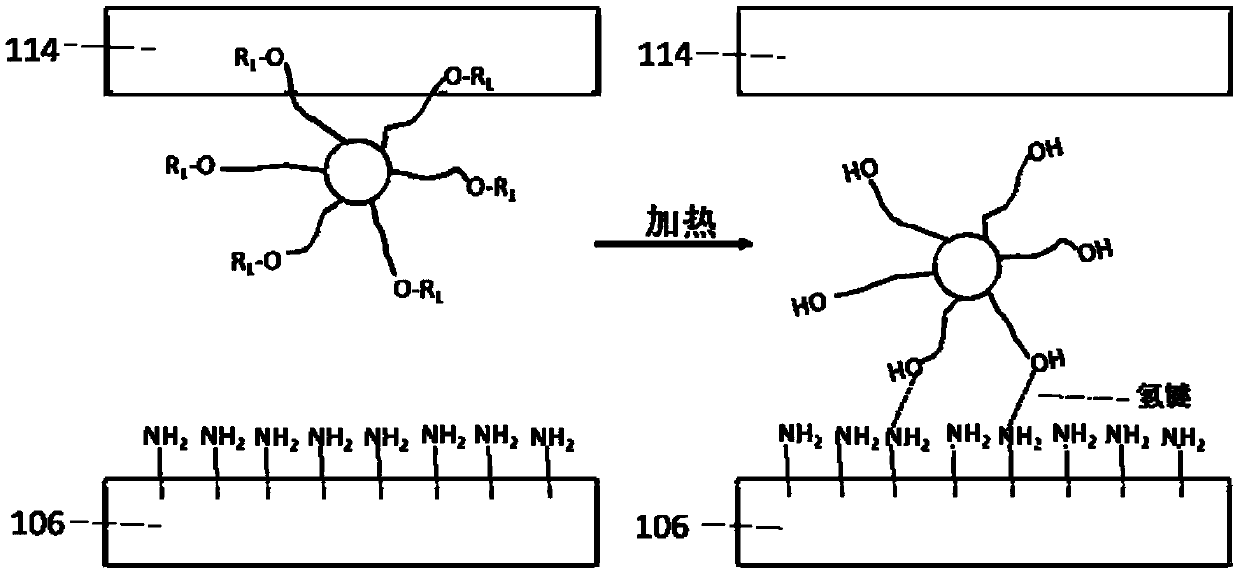

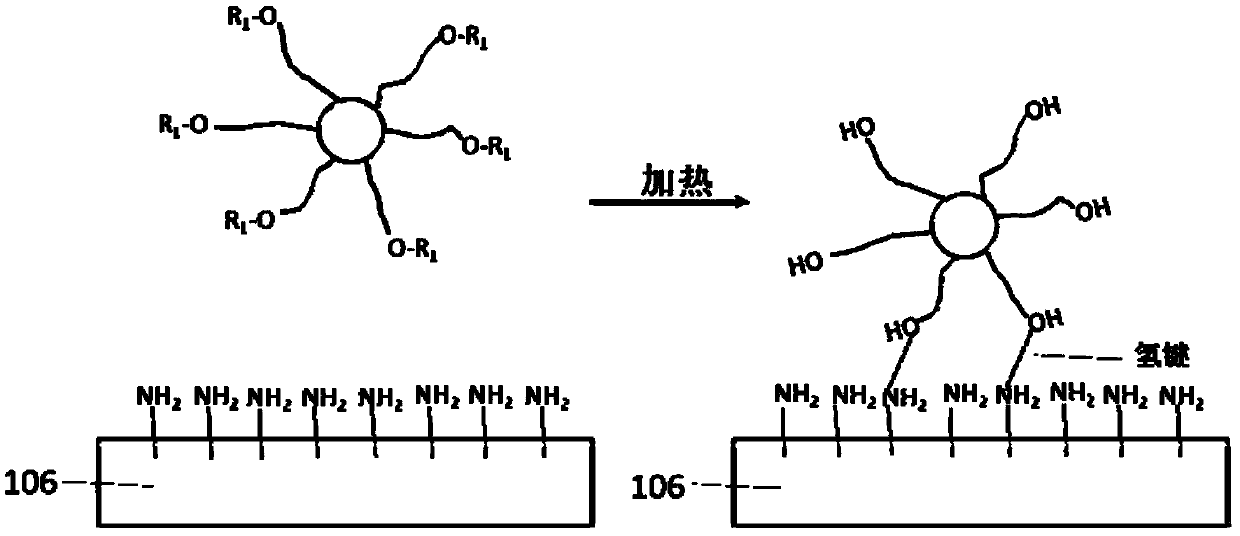

[0061] Figure 2A-2K It is a schematic diagram illustrating each stage of the method for preparing a quantum dot light emitting diode sub-pixel array according to the first embodiment of the present invention through cross-sectional views. In a specific example, for example, the green, blue, and red quantum dot light-emitting diode sub-pixel arrays can be separately prepared on the substrate by a laser heating method.

[0062] First of all, Figure 2A The initial structure of this embodiment is shown. The initial structure is the base substrate 202, the material of which is well known in the art, such as glass or quartz. The base substrate 202 may be transparent or opaque. The base substrate 202 is cleaned using standard methods.

[0063] Next, like Figure 2B As shown, an optional thin film transistor (TFT) array 204 is prepared on a base substrate 202. The specific manufacturing method and structure of the TFT array are not limited, and they can be methods and structures known...

no. 2 example

[0086] In the second embodiment, a method similar to the first embodiment is used to independently realize the transfer of each thermally sensitive quantum dot material layer to the corresponding sub-pixel area. The difference between the second embodiment and the first embodiment is that instead of using the carrier substrate of the thermally sensitive quantum dot material layer, a thermally conductive mask is directly used to carry the thermally sensitive quantum dot material. In the following description, the parts in the second embodiment that are similar to those in the first embodiment will not be described in detail.

[0087] Figure 3A-3H It is a schematic diagram illustrating each stage of the method for preparing a quantum dot light emitting diode sub-pixel array according to the second embodiment of the present invention through cross-sectional views.

[0088] Such as Figure 3A with 3B As shown, an optional TFT array 304 is prepared on the cleaned base substrate 302, an...

no. 3 example

[0104] In the third embodiment, a heating method similar to the first embodiment is used to independently realize the transfer of each thermally sensitive quantum dot material layer to the corresponding sub-pixel area. The main difference between the third embodiment and the first embodiment is that instead of using the carrier substrate of the thermally sensitive quantum dot material layer, the thermally sensitive quantum dot material layer is directly coated on the quantum dot receiving layer. In the following description, the parts in the third embodiment that are similar to those in the first embodiment will not be described in detail.

[0105] Figure 4A-4H It is a schematic diagram illustrating each stage of the method for preparing a quantum dot light emitting diode sub-pixel array according to the third embodiment of the present invention through cross-sectional views.

[0106] Such as Figure 4A with 4B As shown, an optional TFT array 404 is prepared on the cleaned base su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resolution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com