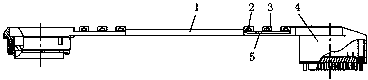

Flat cable and manufacturing method thereof

A technology for flat cables and manufacturing methods, which is applied in the direction of flat/ribbon cables, insulated cables, and bendable cables, etc., which can solve the problems of complicated cable requirements, poor disturbability, and difficult laying, so as to avoid uneven distribution of internal stress , harsh working conditions, and strong bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

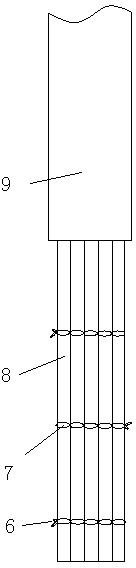

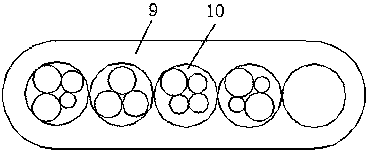

[0023] It can be seen from the background technology that the existing cables are poor in disturbability and easy to be damaged; the inventor initially determined that the reason for the deformation of the cable is that the cable will inevitably produce various types of deformation during the production and processing process. Bending under normal conditions, various bendings cause uneven force and different tightness between the cores, resulting in uneven distribution of internal stress in the insulated cores of the finished cable, and repeated bending of the conductors into "Z" " or "Ω" type, the shielding layer of the wire escapes and is worn out by other shielding layers, forming a short circuit. Since the tensile or compressive deformation of the cable is gradually generated with time or the number of bendings, the deformation is gradually accumulated. Therefore, the degree of harm caused by bending should not be controlled, and the timing of short circuit should not be g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com