Voltage doubler rectifier circuit circuit entity system

A voltage-doubling rectifier circuit and circuit technology, applied in printed circuits, printed circuits, printed circuits connected with non-printed electrical components, etc., can solve the problems of limited insulation capacity, poor electrical performance, and high cost, and achieve space occupation The effect of shrinking, improving work reliability, and improving withstand voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

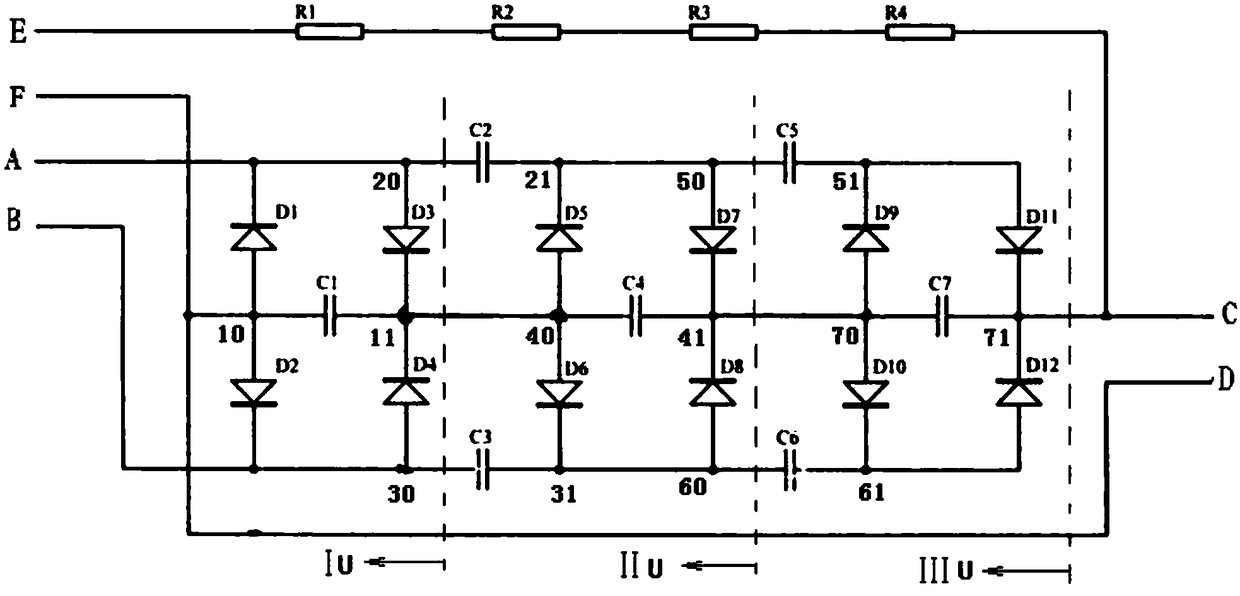

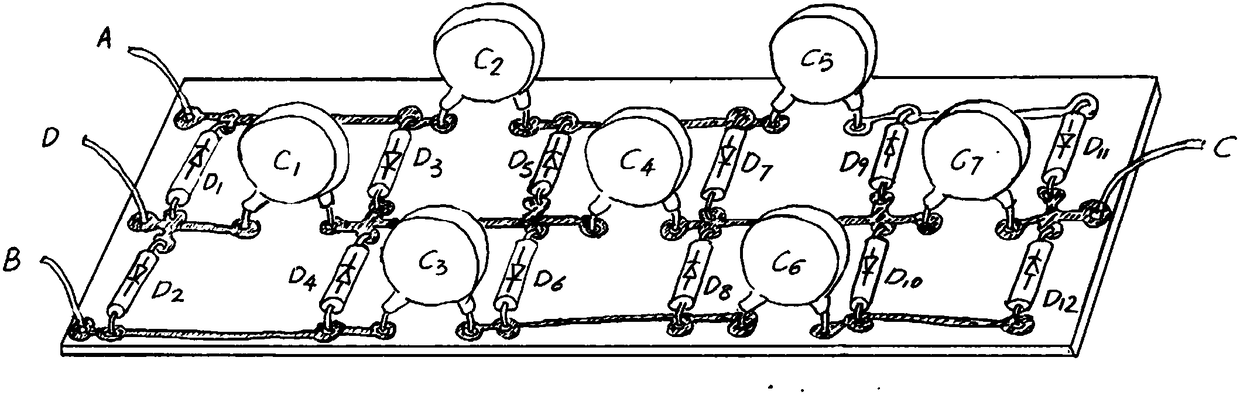

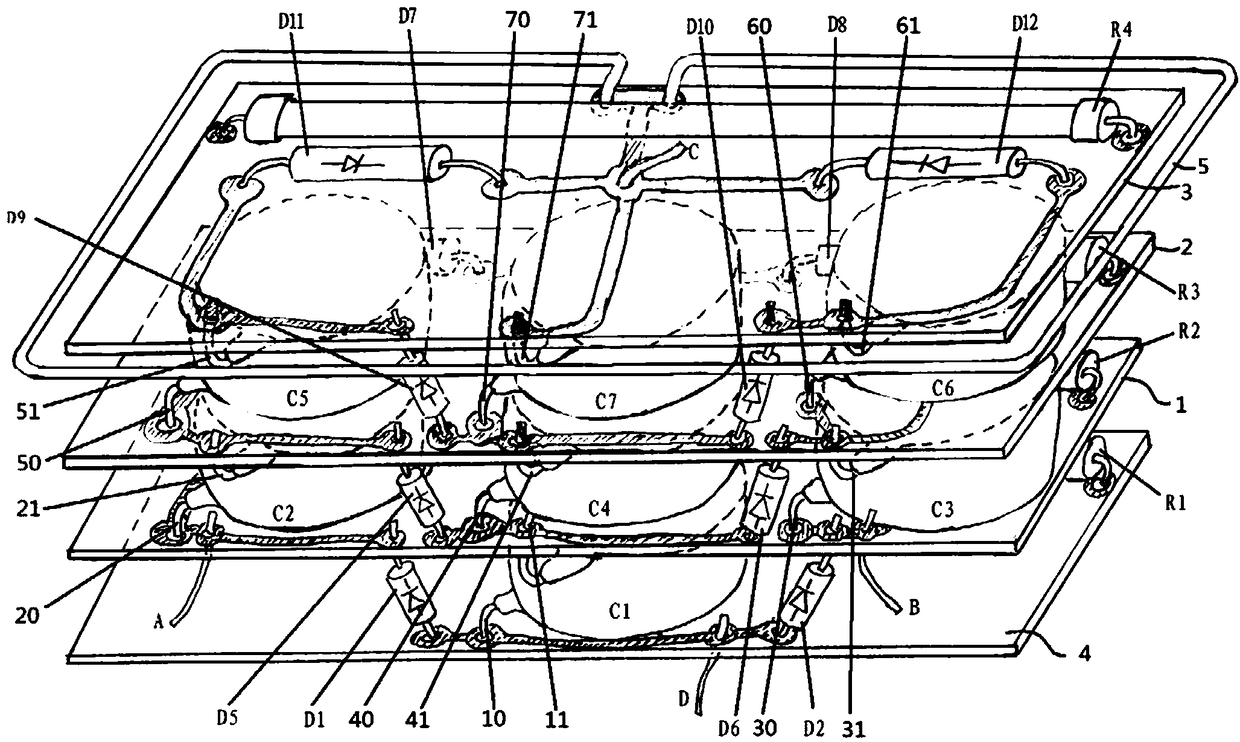

[0008] by figure 1 The shown triple full-wave voltage doubling rectifier circuit is taken as an example, and the technical content of the voltage doubling rectifier circuit circuit entity system of the application of the present invention is described in detail. The triple voltage steps of the triple voltage full-wave rectifier circuit in this embodiment are respectively arranged on each voltage doubler step circuit board according to the gradient level, and each voltage doubler step is respectively arranged on each layer of the vertical spacing distribution according to the voltage doubler sequence On the voltage doubling step circuit boards 1, 2, and 3, in each voltage doubling step, for example, the two pins 10 and 11 of the capacitor C1 of the first voltage doubling step IU are welded to the substrate 4 and the upper voltage doubling step circuit board 1 respectively Above, the two pins 20 and 21, 30 and 31, 40 and 41 of each capacitor of the capacitors C2, C3, and C4 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com