Oxygen-isolating microwave fixation method for high-quality tea

A microwave killing green, high-quality technology, which is applied in the field of tea processing, can solve the problems of unfavorable tea preservation, affecting tea quality, and reducing the aging speed, and achieves the advantages of reducing the generation of organic free radicals, improving the appearance quality, and reducing the aging speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

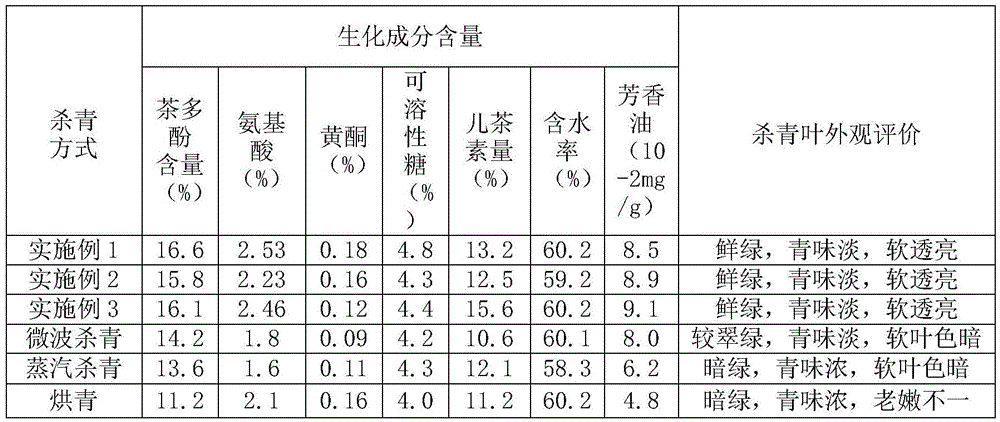

Examples

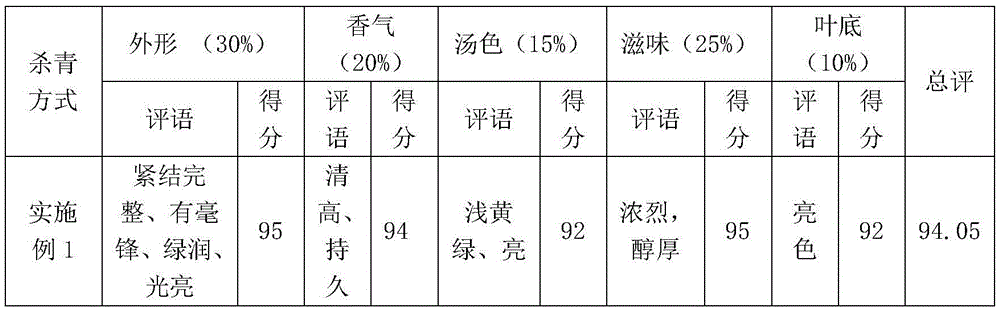

Embodiment 1

[0031] A kind of oxygen-isolated microwave greening method for high-quality tea, comprising the following steps:

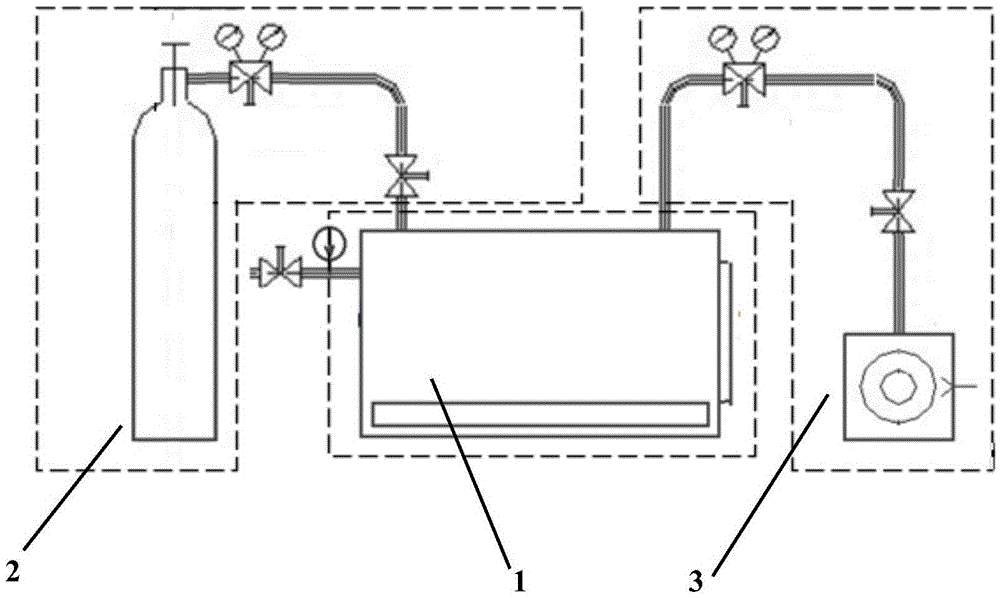

[0032] (1) Please refer to figure 1 , using a microwave de-enzyming device with a gas-filling device 2 and a vacuum device 3 for microwave de-enzyming of tea leaves;

[0033] (2) Set the temperature in the microwave killing chamber 1 to 150°C, and preheat the microwave killing chamber 1;

[0034] (3) After the temperature in the microwave fixing chamber 1 reaches the set temperature and stabilizes, put 2.0kg of fresh Longjing green tea leaves into the microwave fixing chamber 1, and immediately seal the microwave killing chamber 1;

[0035] (4) Use vacuum device 3 to evacuate the microwave fixing chamber 1 to an absolute pressure of 0.01 MPa or less, and use the protective gas filling device 2 to fill nitrogen in the microwave fixing chamber 1 until the absolute pressure in the microwave fixing chamber 1 is 0.06 MPa;

[0036] (5) Step (4) is repeated 2-5 times t...

Embodiment 2

[0039] A kind of oxygen-isolated microwave fixing method for high-quality tea, comprising the following steps:

[0040] (1) Please refer to figure 1 , using a microwave de-enzyming device with a gas-filling protective gas device 2 and a vacuum device 3 to perform microwave de-enzyming of tea leaves;

[0041] (2) Set the temperature in the microwave killing chamber 1 to 120°C, and preheat the microwave killing chamber 1;

[0042] (3) After the temperature in the microwave fixing chamber 1 reaches the set temperature and stabilizes, put 3.0kg of fresh Longjing green tea leaves into the microwave fixing chamber 1, and immediately seal the microwave fixing chamber 1;

[0043] (4) Use vacuum device 3 to evacuate the vacuum in microwave fixing chamber 1 to below the absolute pressure of 0.01 MPa, and use gas filling device 2 to fill carbon dioxide in microwave fixing chamber 1 until the absolute pressure in microwave fixing chamber 1 is 0.08 MPa;

[0044] (5) Step (4) is repeated 2-...

Embodiment 3

[0047] A kind of oxygen-isolated microwave greening method for high-quality tea, comprising the following steps:

[0048] (1) Please refer to figure 1 , using a microwave de-enzyming device with a gas-filling device 2 and a vacuum device 3 for microwave de-enzyming of tea leaves;

[0049] (2) Set the temperature in the microwave killing chamber 1 to 180°C, and preheat the microwave killing chamber 1;

[0050] (3) After the temperature in the microwave fixing chamber 1 reaches the set temperature and stabilizes, put 3.0kg of fresh Longjing green tea leaves into the microwave fixing chamber 1, and immediately seal the microwave fixing chamber 1;

[0051] (4) Use the vacuum device 3 to evacuate the vacuum in the microwave fixing chamber 1 to an absolute pressure below 0.01 MPa, use the protective gas filling device 2 to fill the microwave fixing chamber 1 with nitrogen for protection, and continue to pass nitrogen to maintain the microwave fixing chamber 1 Absolute pressure 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com