A superfine pulverizer that can destroy material circulation during crushing

A technology of ultra-fine pulverizer and materials, which is applied in feed, grain processing, food science, etc. It can solve the problems of high energy consumption, equipment increase, and area construction cost increase, so as to improve the service life, increase the impact effect, and improve the pulverization. yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

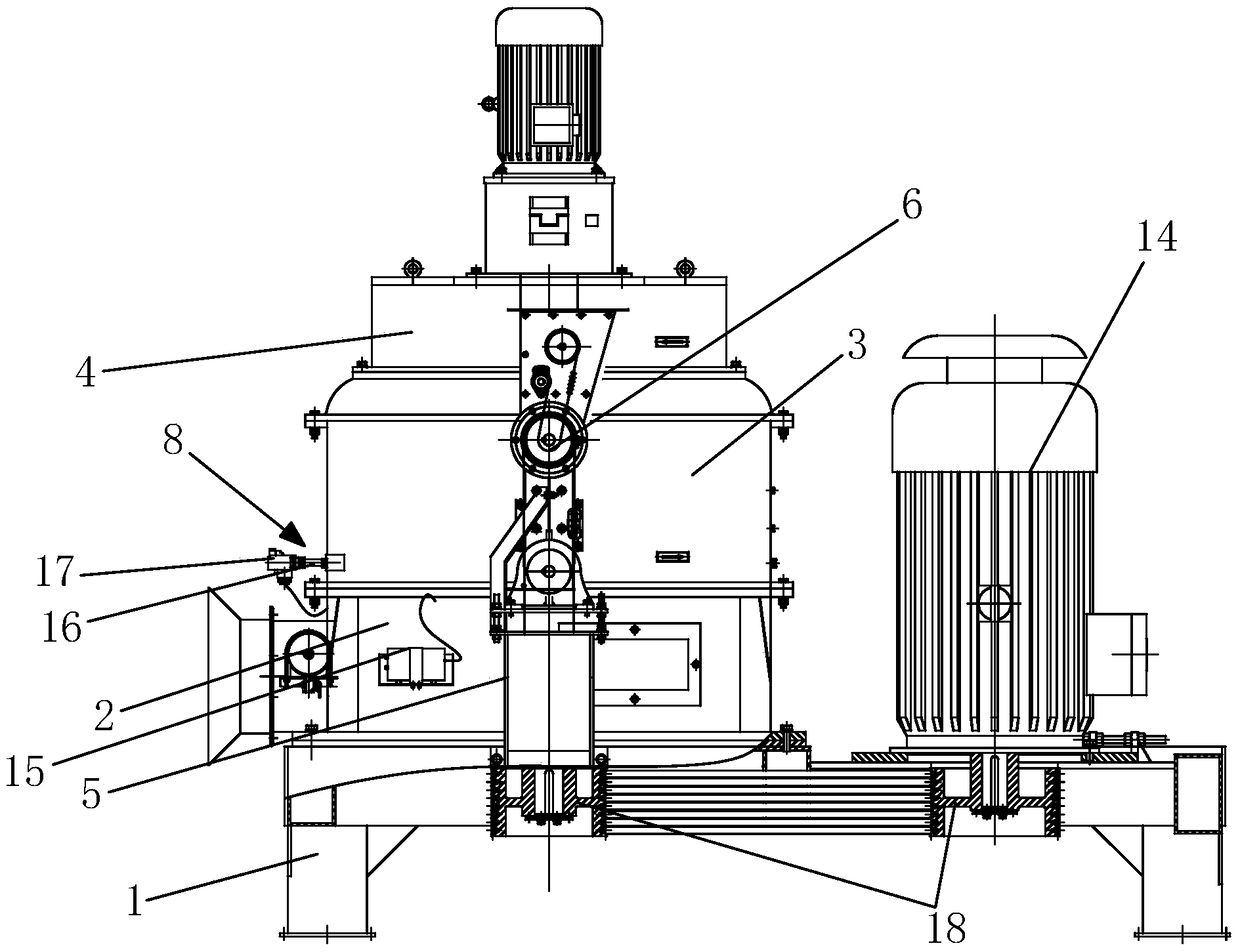

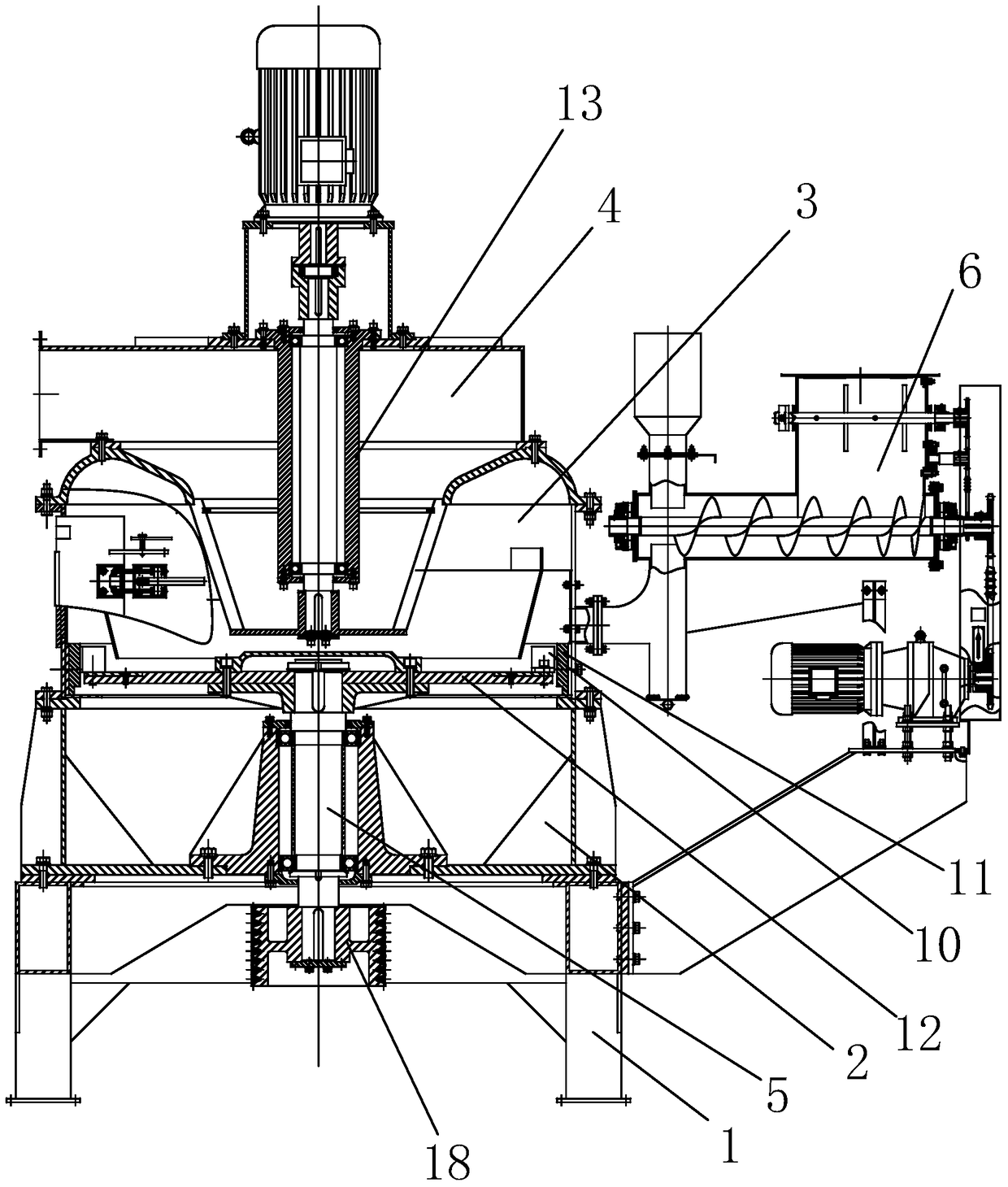

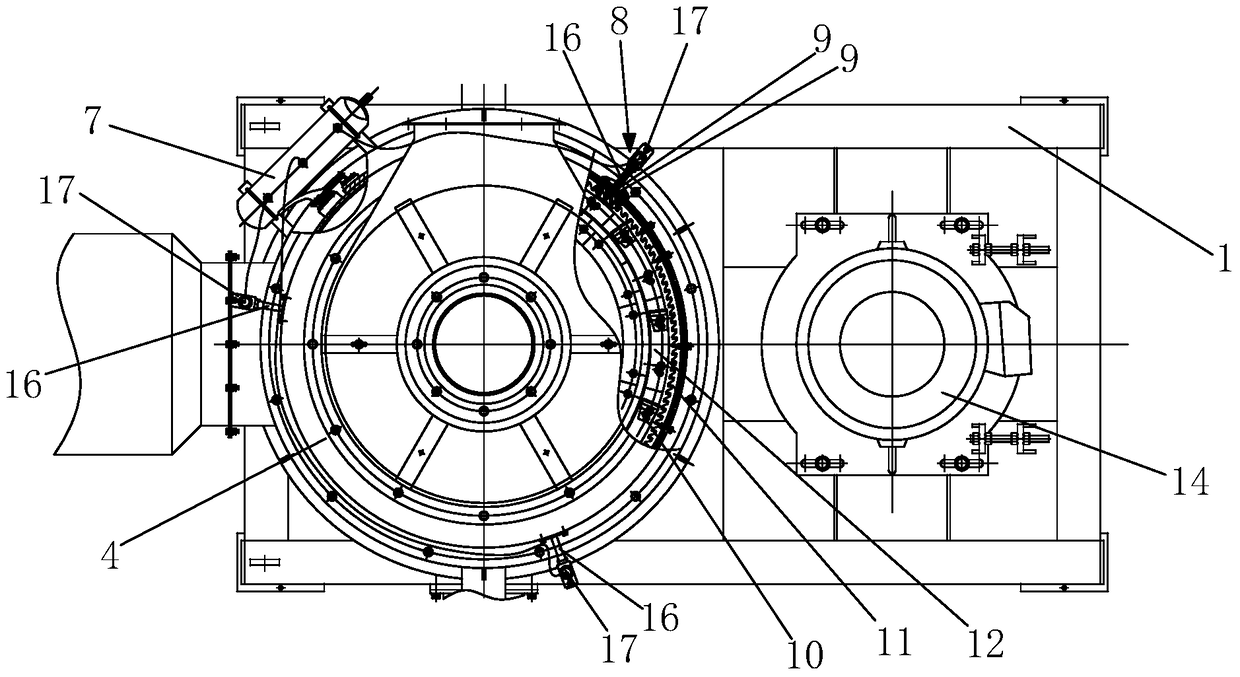

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

[0020] like Figures 1 to 5 The shown ultrafine pulverizer, which can destroy the material circulation during pulverization, includes a rack 1, a clean room 2 arranged on the rack 1, a pulverizing room 3 arranged on the top of the clean room 2, and a The discharge chamber 4, the pulverizing main shaft 5 arranged in the clean room 2, the pulverizing shaft drive motor 14 that drives the pulverizing main shaft 5 to rotate (the pulverizing main shaft 5 rotates relative to the clean room 2 and the pulverizing chamber 3), the feeder installed on the frame 1 The feeding system 6, the feeding outlet of the feeding system 6 is connected with the feeding port of the crushing chamber 3, the top of the purification chamber 2 is communicated with the bottom of the crushing chamber 3, and the discharging chamber 4 is provided with a grading impelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com