Suspension type deflection mechanical hand and stamping production line thereof

A manipulator and suspension technology, applied in the direction of manipulators, metal processing equipment, feeding devices, etc., can solve the problems of severe vibration, slow running speed, and increased production costs, and achieve high positioning accuracy, fast running speed, and small vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

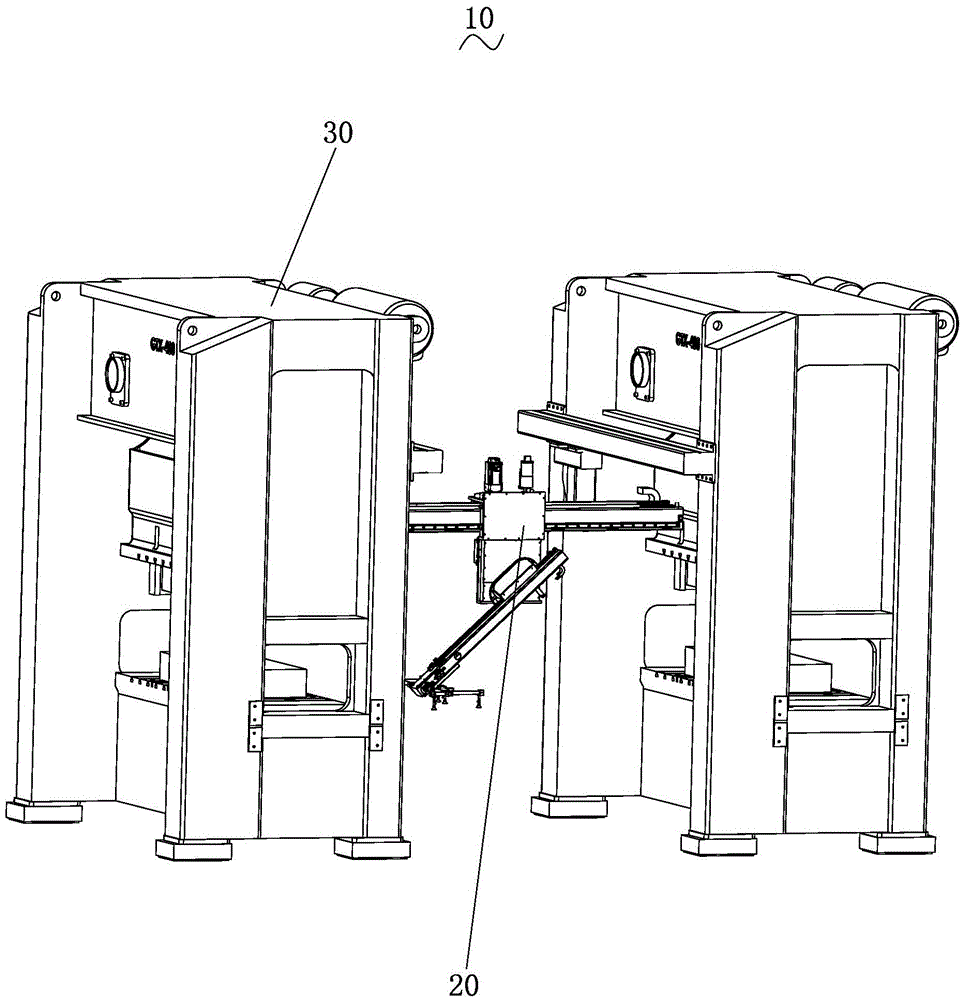

[0030] Such as figure 1 Shown is a structural diagram of a stamping assembly line 10 according to an embodiment of the present invention. The stamping assembly line 10 includes a suspended yaw manipulator 20 and a plurality of punches 30 arranged in sequence, and the suspended yaw manipulator 20 is set between two adjacent punches 30 . The suspended yaw manipulator 20 is arranged between the two punches 30, and the processed workpiece on the punch press 30 is transferred by the suspended yaw manipulator 20.

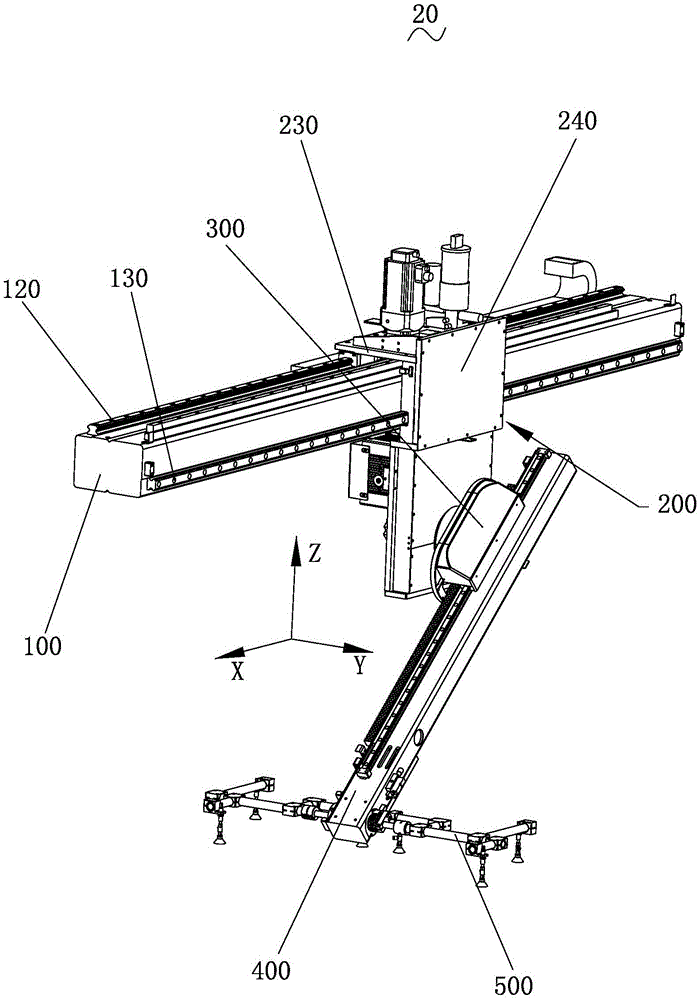

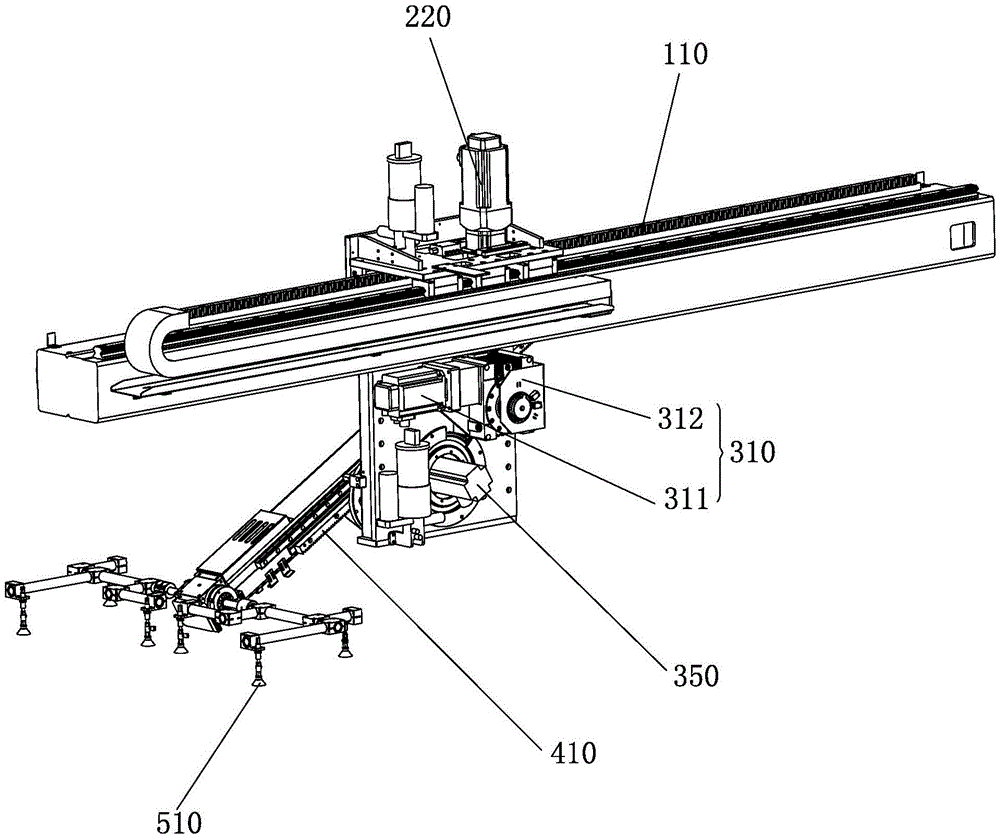

[0031] Such as figure 2 Shown is a structural diagram of a suspended yaw manipulator 20 according to an embodiment of the present invention. The suspended yaw manipulator 20 includes: a beam 100 , a slider 200 , a swing plate 300 , an arm bar 400 and a bar 500 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com