Longitudinal excitation type ultrasonic vibration milling cutter handle device

An ultrasonic vibration, milling cutter technology, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problem of high price, and achieve the effect of solving the heating problem, convenient disassembly and assembly, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

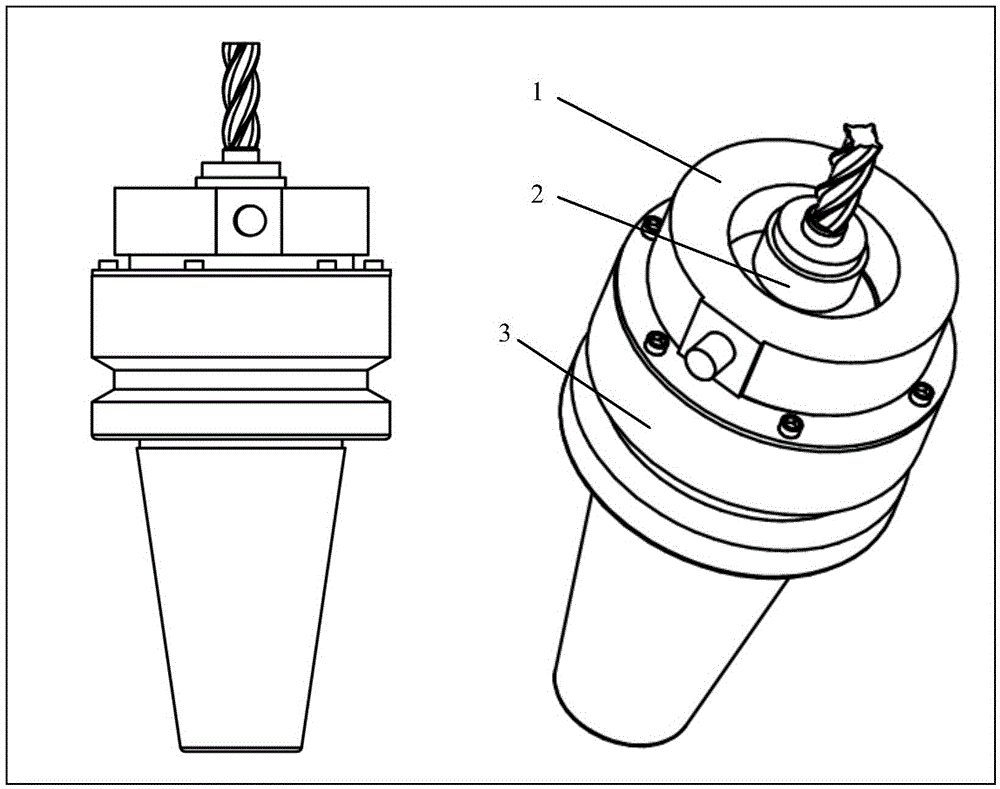

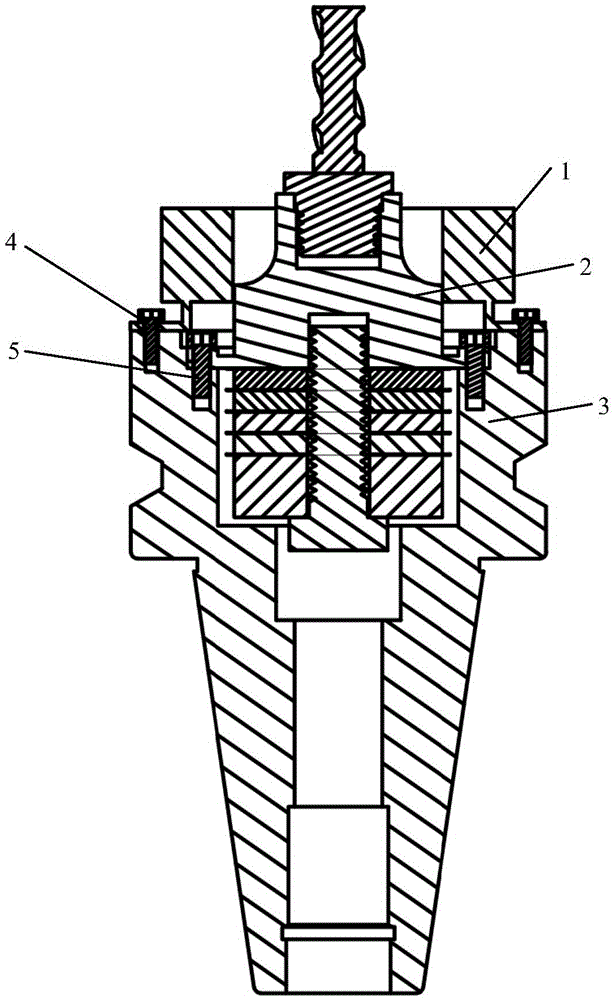

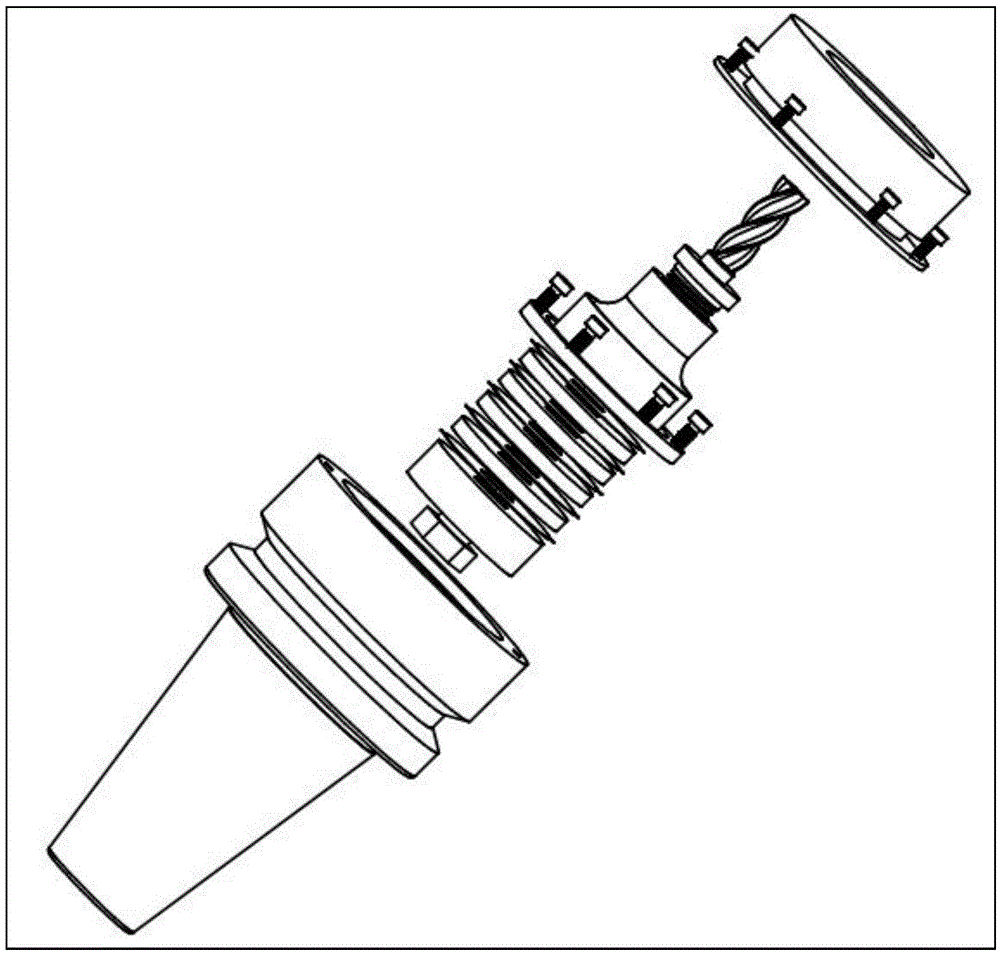

[0040] See figure 1 —— image 3 , The present invention is a longitudinal excitation type ultrasonic vibration milling tool holder device, the components include: conductive slip ring 1, ultrasonic milling transducer 2, non-standard BT50 tool holder 3 three parts. The connection relationship between them is: the ultrasonic vibration milling transducer 2 is connected with the non-standard BT50 tool holder 3 through the flange through the standard M4 bolt 5, and finally the conductive slip ring 1 is fixed on the Non-standard BT50 handle 3.

[0041] 1. Conductive slip ring 1

[0042] Conductive slip ring 1 is a disc-shaped piece with a round hole in the middle and power supply input and output ports. Its function is to provide excitation voltage for the ultrasonic tool holder in high-speed rotation; the conductive slip ring stator is provided with sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com