Method for preparing size-controllable NaY molecular sieve

A technology for controlling size and molecular sieve, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high production cost, complex process, pipeline blockage, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

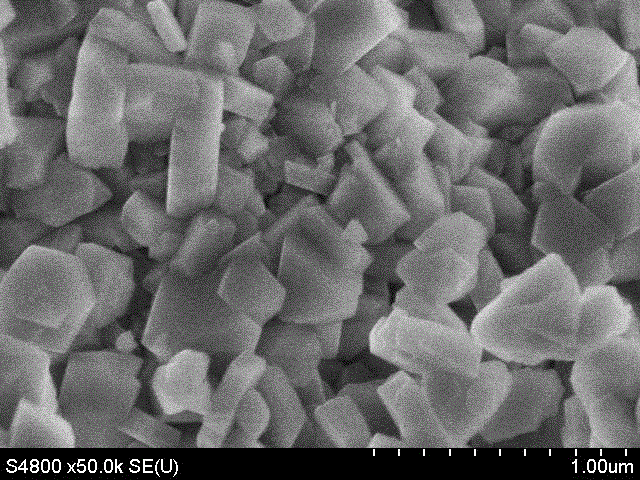

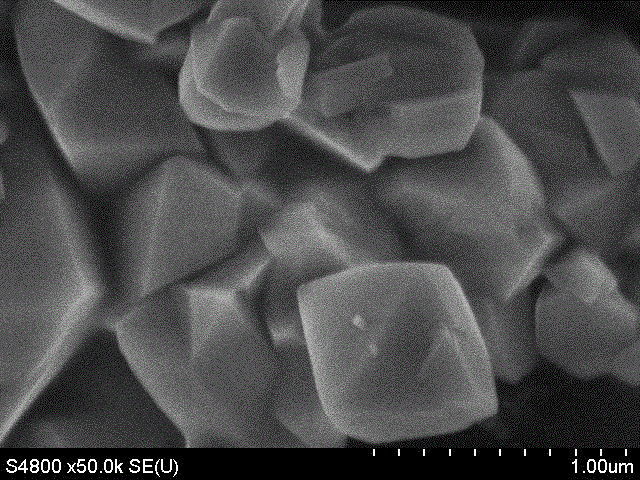

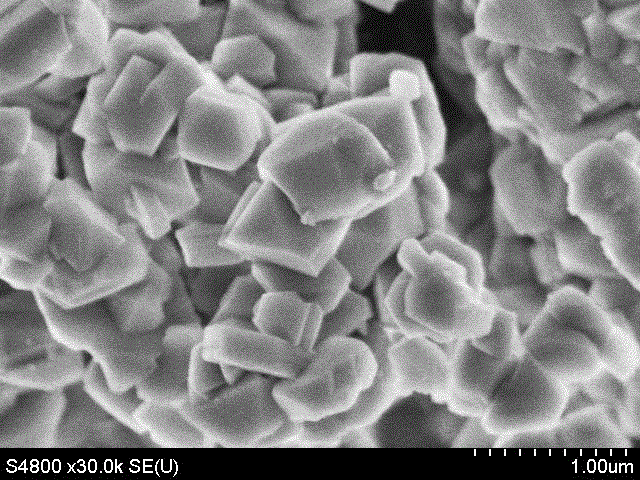

Image

Examples

Embodiment 1

[0022] Directing agent preparation

[0023] 854mL peralkaline sodium metaaluminate solution (Na 2 O content 278g / L, Al 2 o 3 Content 40.3g / L, specific gravity 1.326, product of Sinopec Catalyst Changling Branch) added to 1200mL water glass (SiO 2 Content 253.5g / L, modulus 3.25, specific gravity 1.256, product of Sinopec Catalyst Changling Branch), after mixing evenly, aging at room temperature for 24h to obtain the molar ratio Na 2 O: SiO 2 :Al 2 o 3 :H 2 O=16:15:1:320 directing agent.

[0024] gelation process

[0025] In the gelling kettle, according to the synthetic molar ratio Na 2 O: SiO 2 :Al 2 o 3 :H 2 O=2.70:8.4:1:209 (directing agent accounts for 5% of the aluminum source in the feed), first add water glass solution, heat up to 85-90°C, add directing agent under strong stirring conditions, stir for 5 minutes, and then Add sulfuric acid deionized water, aluminum sulfate and low-alkali sodium metaaluminate solution to the medium, keep the temperature at 85...

Embodiment 2

[0029] Directing agent preparation

[0030] 854mL peralkaline sodium metaaluminate solution (Na 2 O content 278g / L, Al 2 o 3 Content 40.3g / L, specific gravity 1.326, product of Sinopec Catalyst Changling Branch) added to 1200mL water glass (SiO 2 Content 253.5g / L, modulus 3.25, specific gravity 1.256, product of Sinopec Catalyst Changling Branch), after mixing evenly, aging at room temperature for 24h to obtain the molar ratio Na 2 O: SiO 2 :Al 2 o 3 :H 2 O=16:15:1:320 directing agent.

[0031] gelation process

[0032] In the gelling kettle, according to the synthetic molar ratio Na 2 O: SiO 2 :Al 2 o 3 :H 2 O=2.70:8.4:1:209 (directing agent accounts for 5% of the aluminum source in the feed), first add water glass solution, heat up to 25-30°C, add directing agent under strong stirring conditions, stir for 20 minutes, and then Add sulfuric acid deionized water, aluminum sulfate and low-alkali sodium metaaluminate solution to the medium, keep the temperature at 2...

Embodiment 3

[0036] Directing agent preparation

[0037] 854mL peralkaline sodium metaaluminate solution (Na 2 O content 278g / L, Al 2 o 3 Content 40.3g / L, specific gravity 1.326, product of Sinopec Catalyst Changling Branch) added to 1200mL water glass (SiO 2 Content 253.5g / L, modulus 3.25, specific gravity 1.256, product of Sinopec Catalyst Changling Branch), after mixing evenly, aging at room temperature for 24h to obtain the molar ratio Na 2 O: SiO 2 :Al 2 o 3 :H 2 O=16:15:1:320 directing agent.

[0038] gelation process

[0039] In the gelling kettle, according to the synthetic molar ratio Na 2 O: SiO 2 :Al 2 o 3 :H 2 O=2.70:8.4:1:209 (directing agent accounts for 5% of the aluminum source in the feed), first add water glass solution, heat up to 55-60°C, add directing agent under strong stirring conditions, stir for 30 minutes, and then Add sulfuric acid deionized water, aluminum sulfate and low-alkali sodium metaaluminate solution to the medium, keep the temperature at 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com