Method for preparing linear macromolecules with controllable molecular weight by solution polycondensation reaction

A technology of solution polycondensation and molecular weight, which is applied to linear polymer devices and the field of linear polymer preparation, can solve problems such as judging the degree of reaction and difficult reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

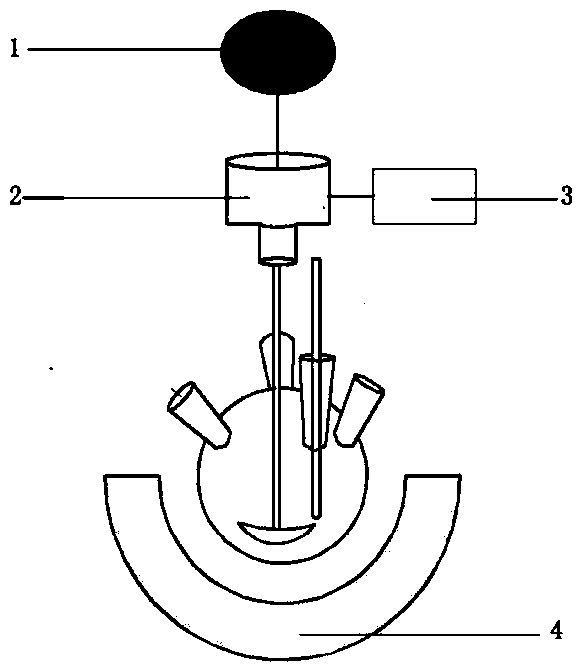

Method used

Image

Examples

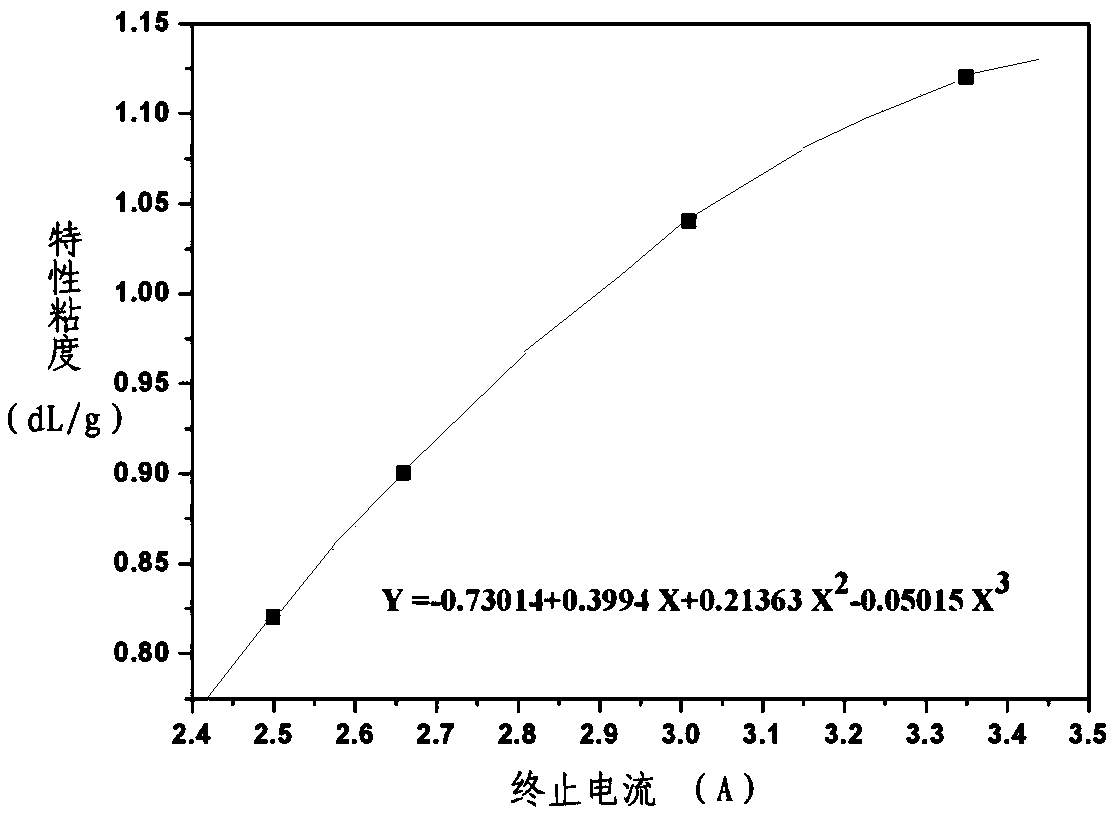

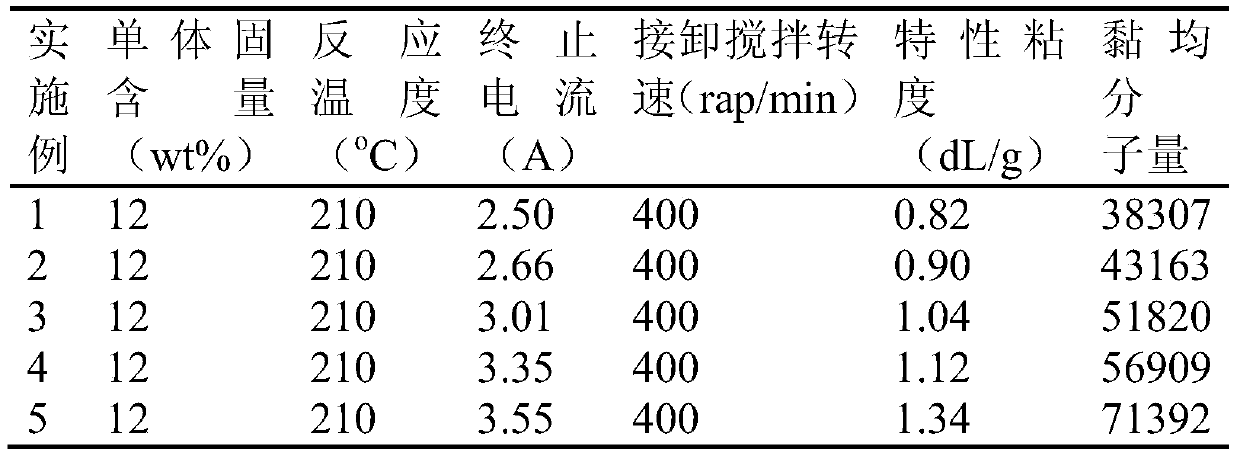

Embodiment 1

[0033] Weigh 500.0g polyphosphoric acid, 29.9gP 2 o 5 (0.211mol) and 33.8g3,3`-diaminobenzidine (0.158mol), add 500mL successively, into the four-necked flask equipped with nitrogen inlet, mechanical stirring, condensing reflux tube and thermometer, and use electric heating mantle to gradually heat up to 210°C. Control the temperature to 210° C., the rotation speed to 390-410 rpm, and add 26.2 g of isophthalic acid (0.158 mol). When the temperature is kept at about 210°C and the rotational speed is maintained at 400 rap / min, when the current reaches 2.50 A, 15 mL of deionized water is quickly added to the solution, and the solution is quickly poured into deionized water. After standing overnight, take it out, dry it, crush it, and rinse it repeatedly with deionized water until the solution becomes neutral. Dry the solid to obtain powdered mPBI. The intrinsic viscosity measured by the Ubbelohde viscometer is 0.82dL / g, and the calculated molecular weight is the viscosity ave...

Embodiment 2

[0035] Weigh 500.0g polyphosphoric acid, 29.9gP 2 o 5 (0.211mol) and 33.8g3,3`-diaminobenzidine (0.158mol), add 500mL successively, into the four-necked flask equipped with nitrogen inlet, mechanical stirring, condensing reflux tube and thermometer, and use electric heating mantle to gradually heat up to 210°C. Control the temperature to 210° C., the rotation speed to 390-410 rpm, and add 26.2 g of isophthalic acid (0.158 mol). When the temperature is kept at about 210°C and the rotation speed is maintained at 400 rap / min, when the current reaches 2.66A, 15 mL of deionized water is quickly added to the solution, and the solution is quickly poured into deionized water. After standing overnight, take it out, dry it, crush it, and rinse it repeatedly with deionized water until the solution becomes neutral. Dry the solid to obtain powdered mPBI. The intrinsic viscosity measured by Ubbelohde viscometer is 0.90dL / g, and the calculated viscosity-average molecular weight is 41352....

Embodiment 3

[0037] Weigh 500.0g polyphosphoric acid, 29.9gP 2 o 5(0.211mol) and 33.8g3,3`-diaminobenzidine (0.158mol), add 500mL successively, into the four-necked flask equipped with nitrogen inlet, mechanical stirring, condensing reflux tube and thermometer, and use electric heating mantle to gradually heat up to 210°C. Control the temperature to 210° C., the rotation speed to 390-410 rpm, and add 26.2 g of isophthalic acid (0.158 mol). When the temperature is kept at about 210°C and the rotational speed is maintained at 400 rap / min, when the current reaches 3.01 A, 15 mL of deionized water is quickly added to the solution, and the solution is quickly poured into deionized water. After standing overnight, take it out, dry it, crush it, and rinse it repeatedly with deionized water until the solution becomes neutral. Dry the solid to obtain powdered mPBI. The intrinsic viscosity measured by the Ubbelohde viscometer is 1.04dL / g, and the calculated viscosity-average molecular weight is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com