Arabinogalacto-oligosaccharide and preparation and application thereof

A technology of arabinogalactan and galactooligosaccharides, which is applied in the fields of arabinogalactan and galactooligosaccharides and its preparation and application, can solve the problems of uncontrollable broken glycosidic bond position and less research, and achieve obvious promotion in vitro Growth effect, wide application prospect, effect of molecular weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of Arabinogalactooligosaccharides:

[0047] (1) Degradation: Take 0.1g of arabinogalactan in a 100ml hydrolysis bottle, add 20mL of 0.05mol / L citric acid buffer in the hydrolysis bottle, add β- 1,3-galactosidase (that is, add 10Uβ-1,3-galactosidase per gram of arabinogalactan), add distilled water to make the total volume of enzymolysis 50mL, adjust the pH value to 5.0, in 200 rpm, 45 ° C in a constant temperature shaker for 30 h, centrifuged to remove the precipitate, to obtain the supernatant; continue to add α-arabinosidase (i.e. Add 65Uα-arabinosidase per gram of arabinogalactan), add distilled water to make the total volume of enzymolysis 50mL, adjust the pH value to 5.5, enzymolyze in a constant temperature shaker at 200 rpm and 50°C for 30h, centrifuge Remove the precipitate, and finally obtain the degraded supernatant, that is, the degradation solution.

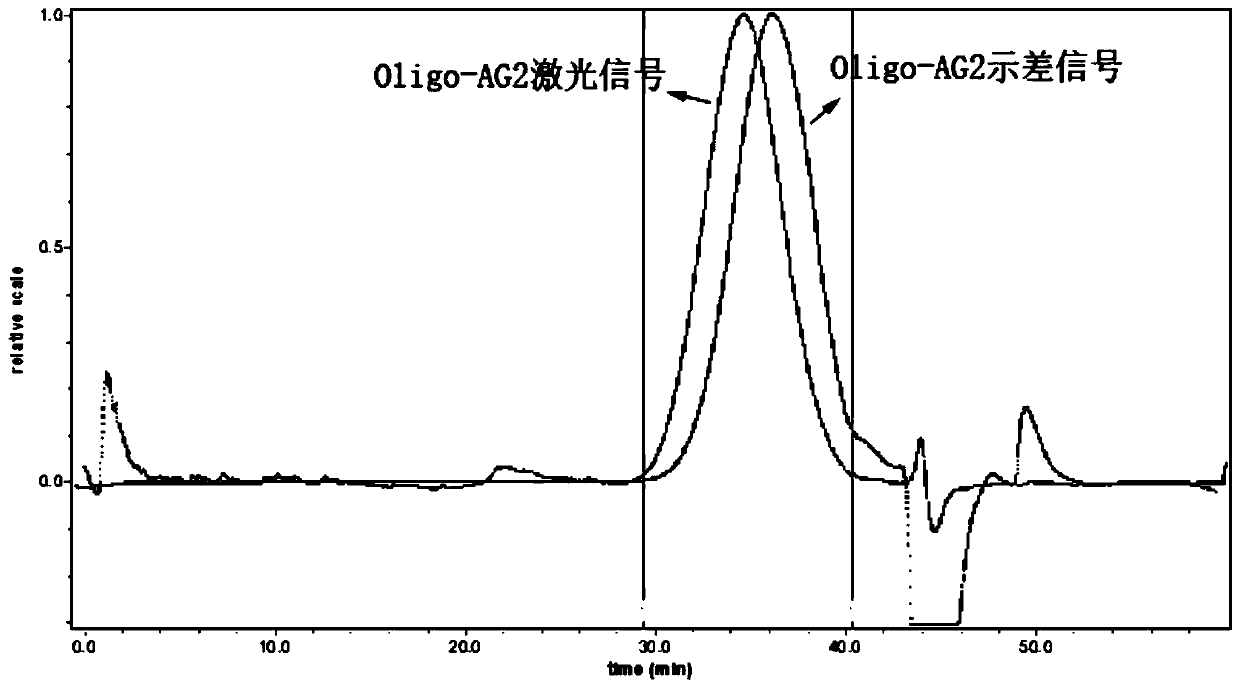

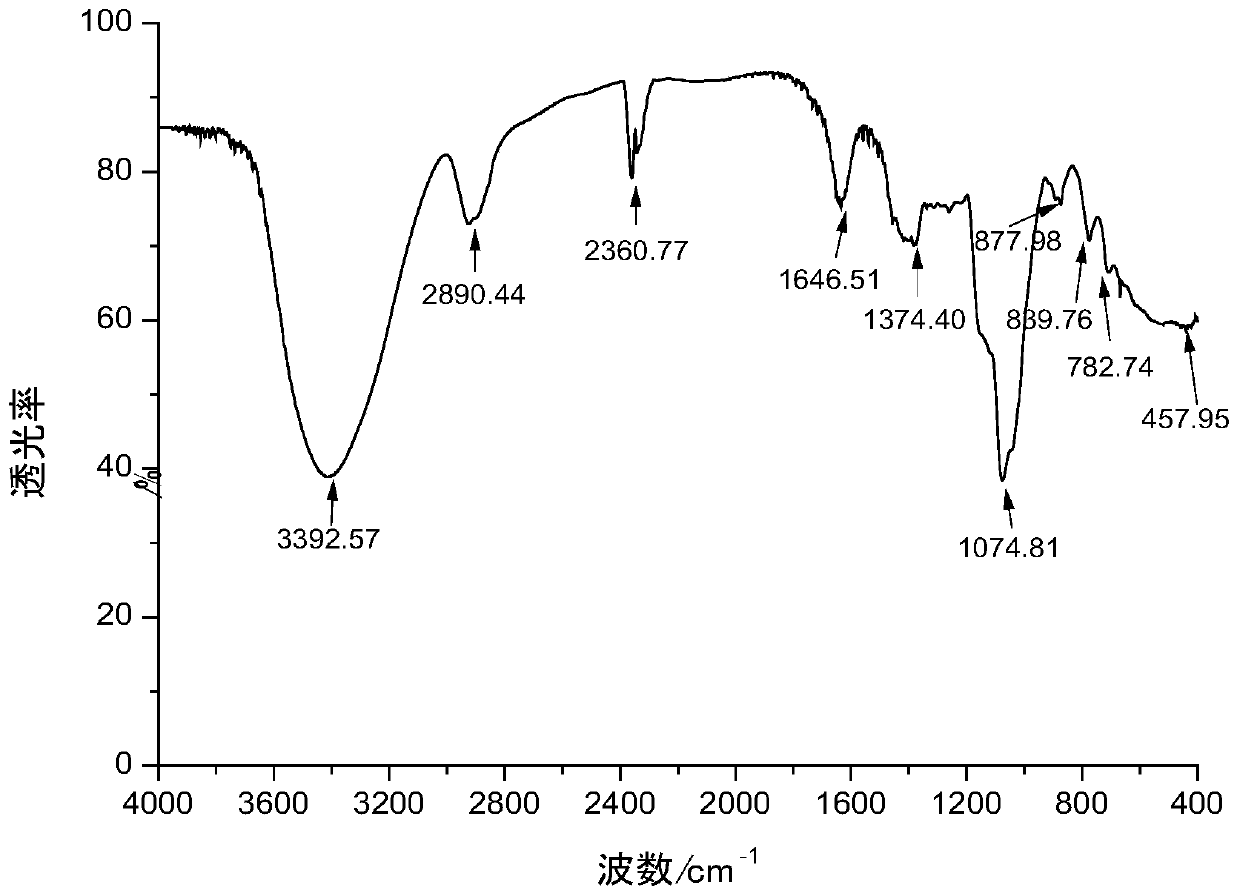

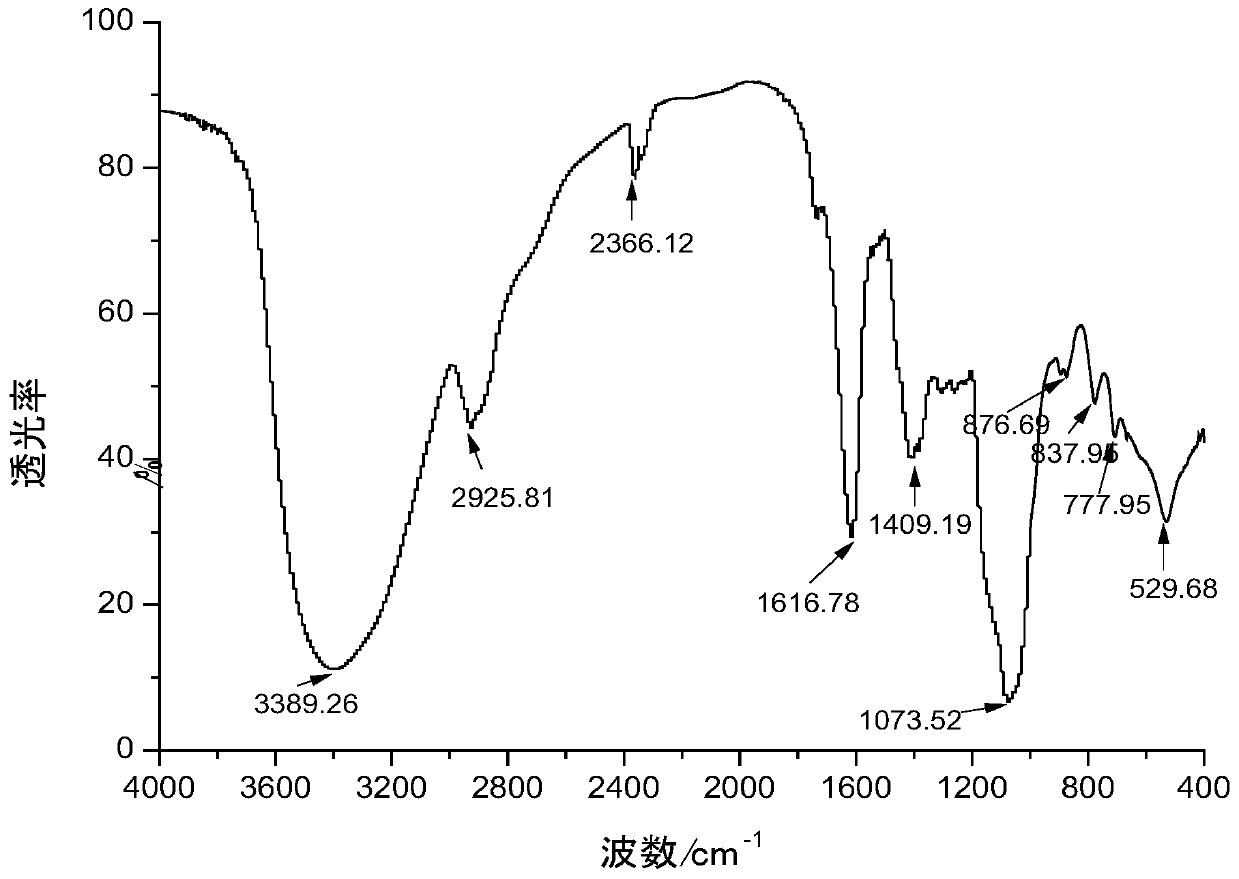

[0048] (2) Membrane separation and purification: Dilute the degradation solution obtained in s...

Embodiment 2

[0052] Preparation of Arabinogalactooligosaccharides:

[0053] (1) Degradation: Take 0.5g arabinogalactan in a 100ml hydrolysis bottle, add 30mL of 0.05mol / L citric acid buffer in the hydrolysis bottle, add β- 1,3-galactosidase (that is, add 45Uβ-1,3-galactosidase per gram of arabinogalactan), add distilled water to make the total volume of enzymolysis 50mL, adjust the pH value to 7.0, in 200 rpm, 55 ° C in a constant temperature shaker for 60 h, centrifuged to remove the precipitate, to obtain the supernatant; continue to add α-arabinosidase (i.e. Add 50Uα-arabinosidase per gram of arabinogalactan), add distilled water to make the total volume of enzymolysis 50mL, adjust the pH value to 7.5, enzymolyze in a constant temperature shaker at 200 rpm and 65°C for 60h, centrifuge Remove the precipitate, and finally obtain the degraded supernatant, that is, the degradation solution.

[0054] (2) Membrane separation and purification: Dilute the degradation solution obtained in step...

Embodiment 3

[0058] Preparation of Arabinogalactooligosaccharides:

[0059] (1) Degradation: Take 0.8g arabinogalactan in a 100ml hydrolysis bottle, add 40mL of 0.05mol / L citric acid buffer in the hydrolysis bottle, add β- 1,3-galactosidase (that is, add 30Uβ-1,3-galactosidase per gram of arabinogalactan), add distilled water to make the total volume of enzymolysis 50mL, adjust the pH value to 5.5, and 200 rev / min, 45 ℃ of constant temperature shaker in enzymolysis 48h, centrifugation removes precipitation, obtains supernatant; Continue to add α-arabinosidase (namely Add 40U α-arabinosidase to each gram of arabinogalactan), add distilled water to make the total volume of enzymolysis 50mL, adjust the pH value to 6.5, enzymolyze in a constant temperature shaker at 200 rpm and 50°C for 50h, centrifuge Remove the precipitate, and finally obtain the degraded supernatant, that is, the degradation solution.

[0060] (2) Membrane separation and purification: Dilute the degradation solution obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com