Deoxidation technique used in low-alloy steel smelting process

A smelting process, low-alloy steel technology, applied in the field of deoxidation process, to achieve the effect of increasing strength, reducing production cost, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

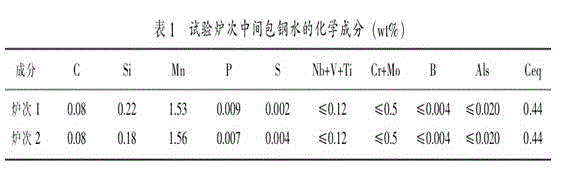

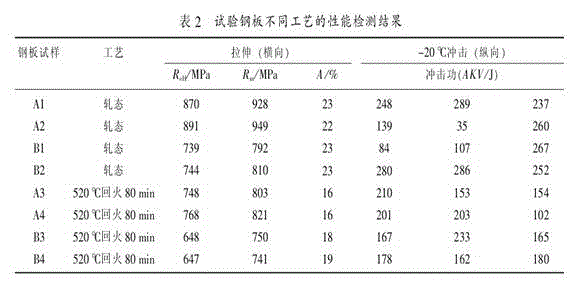

[0018] The process route adopted in the present invention: molten iron pretreatment—120t converter—LF ladle refining—VD vacuum treatment—soft blowing—wide and thick plate continuous casting—five-meter rolling. In order to ensure the success of the test, each process of the test furnace was strictly controlled, and the project team followed up every link of the test process. The content of [C] and [O] at the end of the converter is strict. Si-Mn deoxidation is used in the tapping process. Modifiers can be added appropriately according to the furnace conditions. Alloys other than FeAl are added according to normal operations. When the LF refining enters the station, the molten steel is oxygenated. When the oxygen content in the molten steel reaches a certain level, FeTi alloy is added to the molten steel for deoxidation to ensure the balance of titanium and oxygen in the steel. During the refining process, the molten steel is regularly fixed. Oxygen, alloying operation is carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com