Gas mixing device of burner

A burner and aeration technology, applied in the burner, combustion method, combustion type, etc., can solve the problems of damage to the burner fan, uneven distribution of air volume, restricting the use of the burner, etc., to avoid damage to the fan and aeration effect. Excellent, promoting uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

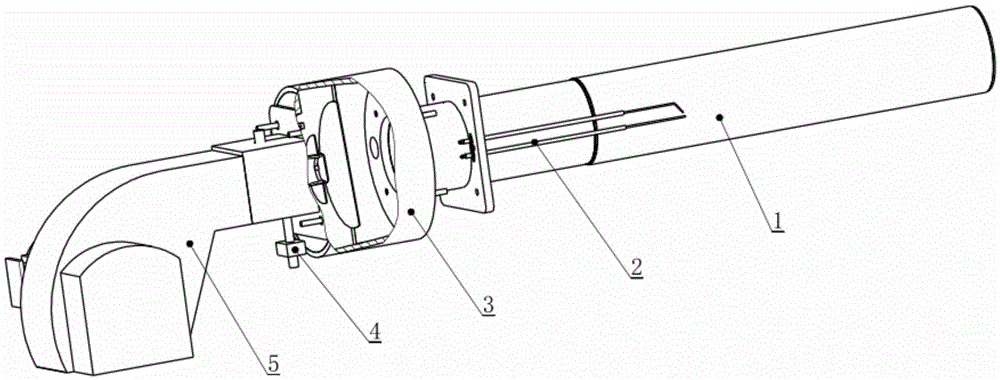

[0041] see figure 1 , the burner in the illustration includes a metal fiber furnace head 1, an ignition needle assembly 2, a gas mixing chamber 3, a gas inlet joint 4, a burner fan 5, etc. The burner in this embodiment is a gun-type burner, and its Burner burner burner 1 adopts metal fiber burner. The metal fiber burner head 1 of the burner is connected to the gas outlet of the gas mixing chamber 3 through a flange connection, the gas inlet joint 4 is connected to the gas outlet assembly in the gas mixing chamber 3, and the ignition needle assembly 2 is fixed on the burner burner head. On the surface of the metal fiber mesh, the air inlet of the gas mixing chamber 3 is connected with the air outlet of the burner fan 5 .

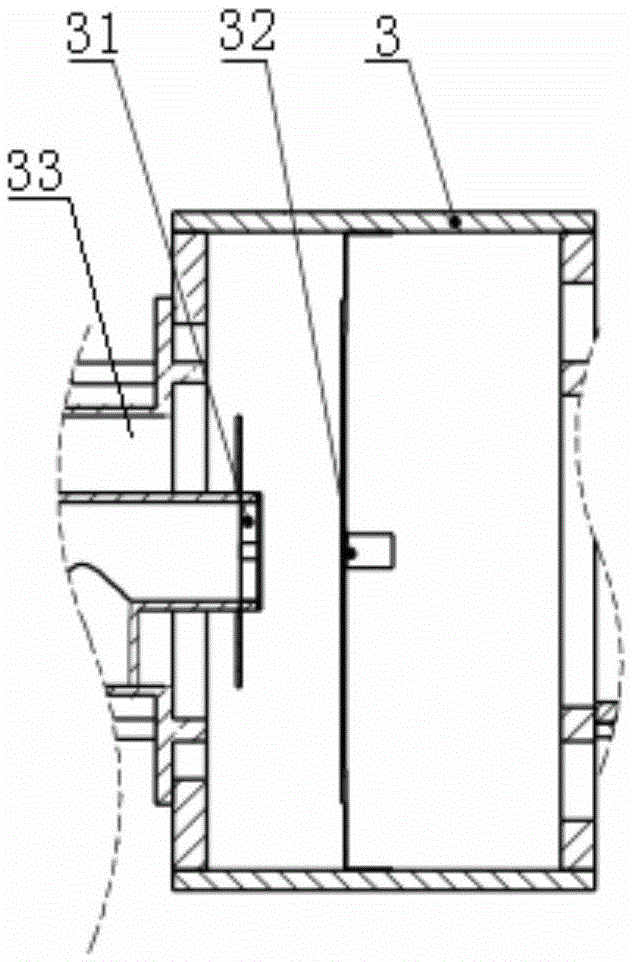

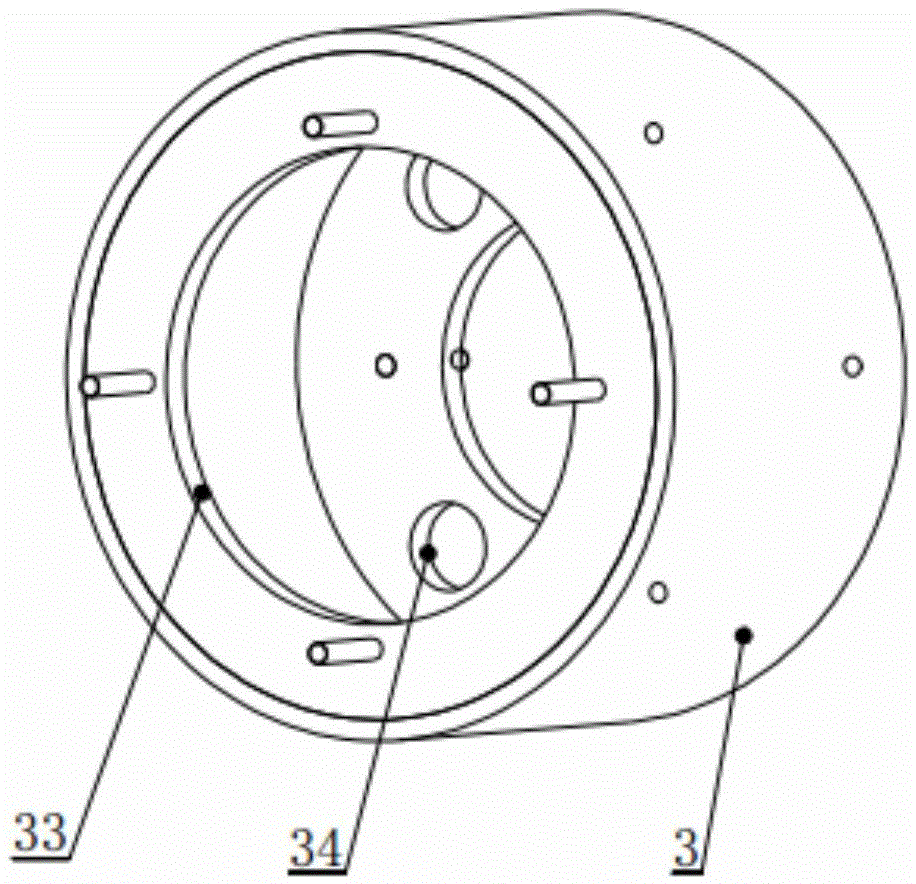

[0042] see in conjunction figure 2 and image 3 , the gas mixing device of this embodiment is arranged in the gas mixing chamber 3, the gas mixing chamber 3 is a cylindrical shell structure, the end is connected to the burner metal fiber furnace head thro...

Embodiment 2

[0046] see in conjunction Figure 5a , Figure 5b The difference between this embodiment and Embodiment 1 is that the baffle plate 312 of the gas outlet assembly in the figure is located at the front end of the gas outlet 313 of the gas outlet pipe 311, and all the gas outlets 313 and air outlets 33 are located at the front end of the gas outlet 313. On the same side of the plate 312, the gas outlet 313 in the present embodiment adopts Kongshi gas outlet, that is, a number of circular holes are evenly opened on the same circumference of the gas outlet pipeline, and the air provided by the burner fan and the gas inlet joint respectively It is mixed with the gas in front of the baffle, and then uniformly disturbed by the baffle to quickly form a uniform mixed gas that is beneficial to combustion.

[0047] The way of gas outlet in this embodiment and embodiment 1 can be adjusted interchangeably.

[0048] Further, a gas mixing part 32 is also provided in the middle of the gas mi...

Embodiment 3

[0051] see Figure 8 and Figure 9 The difference between this embodiment and the previous embodiments is that the air mixing chamber 3 and the cylinder 62 in this embodiment are two-stage double cylinders connected coaxially and integrally, and the diameters of the two sections connected by the axial direction are different. The cylinder of the air mixing chamber is fixedly connected to the air outlet of the burner fan through a flange connection. The internal air mixing device can be arranged with reference to Embodiment 1 and Embodiment 2, and one end of the cylinder connected to the flange assembly The welding furnace head connects the flange 63. This embodiment provides a simplified mode, which can save a connecting flange, and is suitable for the case where the ignition pin is short.

[0052] see Figure 10a , 10b , the diagrams are the combustion effect diagrams of the existing burner head, the flame is darker at the inlet end of the burner, which shows that the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com