Detection and leakage blocking methods of concrete building water leakage

A plugging method and detection method technology, which is applied in the direction of building structure, construction, building maintenance, etc., can solve the problems of low efficiency, not knowing where to start, and no reinforcement compensation, etc., to achieve efficiency improvement and plugging effect Excellent, durability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

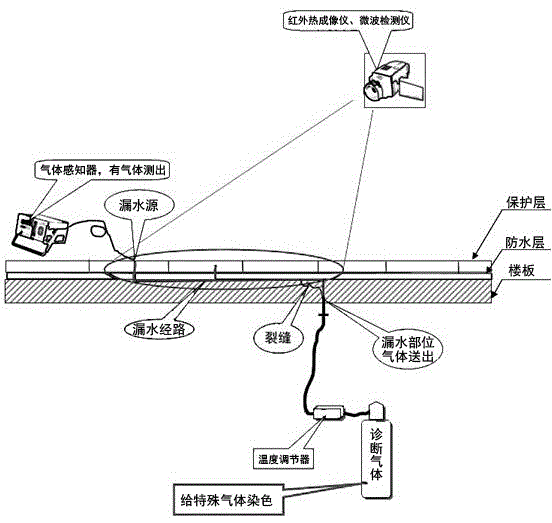

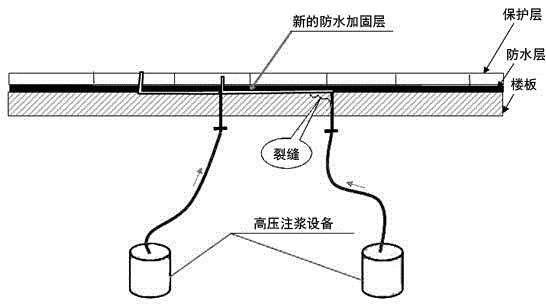

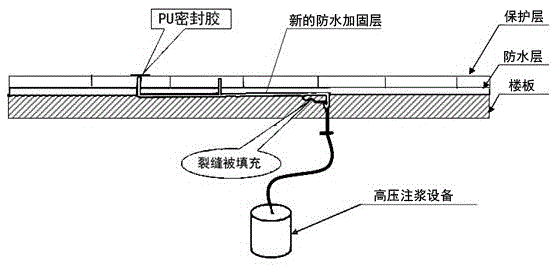

[0050] Such as figure 1 , figure 2 and image 3 As shown, water leakage occurred on the top of a flat-roofed industrial plant. The roof of the factory building is a membrane waterproof roof, and the roof structure layer is a prefabricated reinforced concrete slab, which is filled with fine stone concrete, and the concrete slab is leveled with a cement mortar leveling layer. A membrane waterproof layer is laid on the cement leveling layer, and finally 20mm thick cement mortar is used as the surface protection layer. After investigation, the location of the indoor water leakage point is near the downpipe and close to one side of the wall.

[0051] For the above leaks, take the following detection and plugging methods. The steps are:

[0052] Step (1): Visual inspection of the status quo.

[0053] First, conduct a field survey of the leaking condition of the indoor roof and the current status of the roof near the leaking location through visual observation. Grasp the indo...

Embodiment 2

[0069] Such as figure 1 , figure 2 and image 3 As shown, a concrete building has water leakage from the wall. Cracks are found at the leaking point of the indoor wall, and dark tiles are pasted on the outer wall, but no abnormal phenomenon can be seen by naked eye observation.

[0070] For the above example, the method of determining plugging is as follows:

[0071] Step (1): Visual inspection of the status quo.

[0072] Observe the situation of the indoor water leakage point. If there is a plaster layer on the surface of the water leakage point, remove it so as to observe the actual conditions such as cracks, cracks or honeycombs in the concrete pouring wall.

[0073] Step (2): Status determination records.

[0074] Use infrared thermal imaging camera and wave measuring instrument to measure the condition of the external wall near the water leakage point. Mark the region where the temperature is abnormal and the wave velocity change.

[0075] Step (3): Change in air s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com