MVR (Mechanical Vapor Recompression) multi-level evaporation device

A technology of stage evaporation and stage evaporator, which is applied in the field of MVR evaporation equipment, can solve the problems of low process adaptability, inability to independently complete the use needs, and single MVR evaporator, so as to increase applicability and manufacturability, and facilitate automatic control , Improving the effect of applicability and manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

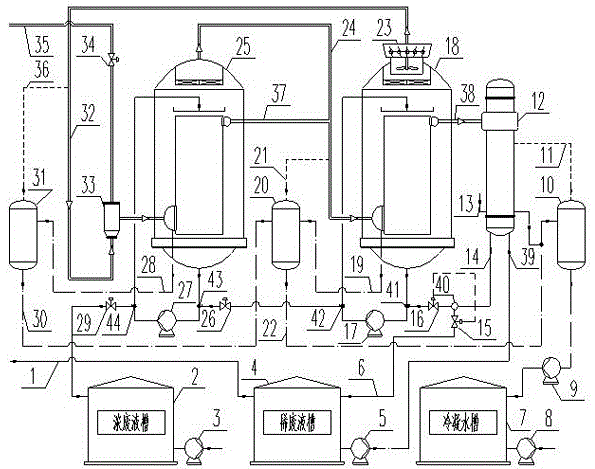

[0026] The present invention is illustrated by taking the MVR system arranged in series in two stages as an embodiment in conjunction with the accompanying drawings.

[0027] In this embodiment, two MVR evaporators connected in series are used, that is, the primary evaporator 25 and the secondary evaporator 18 . A steam surge tank 33 is arranged on the fresh steam supply pipe 35 connected to the steam source, and the steam outlet of the steam surge tank 33 communicates with the steam inlet of the primary evaporator 25 . The secondary steam pipe 24 and the non-condensable steam collection port 37 of the primary evaporator 25 communicate with the steam inlet of the secondary evaporator 18 respectively. The non-condensable steam collection port 38 of the secondary evaporator 18 communicates with the shell side of the surface condenser 12 . The cooling medium inlet 39 and outlet 14 of the tube side of the surface condenser 12 communicate with the outlet of the waste liquid delive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com