A reflux evaporative crystallization device and a method for evaporative crystallization of a mixed solvent

A technology of evaporative crystallization and solvent, which is applied in the field of reflux evaporative crystallization device and mixed solvent evaporative crystallization, which can solve the problems of single structure and achieve the effects of low experimental cost, stable composition and reasonable device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

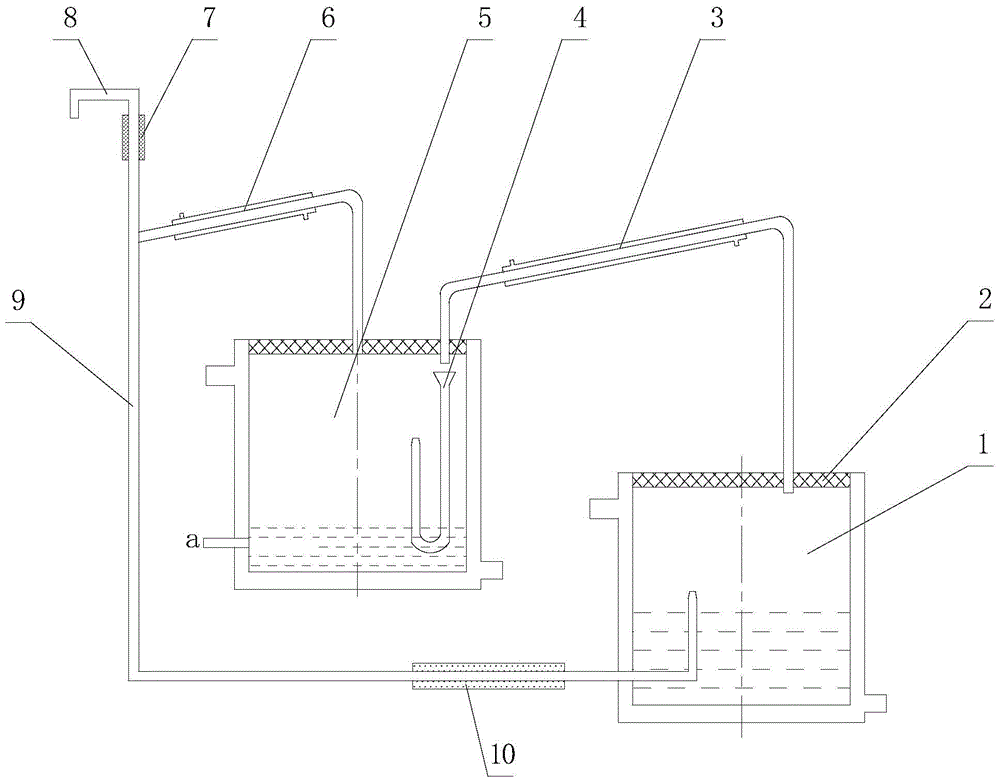

[0022] Depend on figure 1 It can be seen that the reflux evaporation and crystallization device of the present embodiment is composed of a crystallization tank 1, an evaporation reflux tank 5, a sealed top cover 2, a first reflux condensation pipe 3, a U-shaped pipe 4, a second reflux condensation pipe 6, a reflux pipe 9, The third reflux condensing pipe 7, the atmospheric connecting pipe 8 and the preheater 10 are connected to form.

[0023] Among them, the crystallization tank 1 adopts a commonly used jacket structure, which is a jacket that can be filled with a heat medium outside the inner tank, and a high-pressure and high-temperature sealing device made of stainless steel is installed on the top of the crystallization tank 1. There is a sealed top cover 2 of stainless steel heat preservation type, a steam outlet is opened on the top cover, a thermal insulation evaporation liquid output pipe is installed on the steam outlet, and a heat medium inlet and outlet are opened o...

Embodiment 2

[0033]In this embodiment, the crystallization tank 1 adopts a commonly used jacket structure, and a stainless steel heat-preservation type sealed top cover 2 is arranged on the top of the crystallization tank 1, and a steam outlet is provided on the top cover, and a thermal insulation is installed on the steam outlet. The evaporating liquid output pipe, the outlet end of the evaporating liquid output pipe is connected with the steam inlet end of the first reflux condensing pipe 3 with threaded fasteners, in order to ensure the smooth flow of condensate, the first reflux condensing pipe 3 is installed obliquely and connected The water pipeline is connected, and the inclination angle of the first reflux condenser pipe 3 in this embodiment is 30°.

[0034] The evaporation reflux tank 5 of this embodiment is also a jacketed structure, and a U-shaped pipe 4 is fixed with a bracket inside the evaporation reflux tank 5, and one port of the U-shaped pipe 4 is provided with a funnel sha...

Embodiment 3

[0038] In this embodiment, the crystallization tank 1 adopts a commonly used jacket structure, and a stainless steel heat-preservation type sealed top cover 2 is arranged on the top of the crystallization tank 1, and a steam outlet is provided on the top cover, and a thermal insulation is installed on the steam outlet. The evaporating liquid output pipe, the outlet end of the evaporating liquid output pipe is connected with the steam inlet end of the first reflux condensing pipe 3 with threaded fasteners, in order to ensure the smooth flow of condensate, the first reflux condensing pipe 3 is installed obliquely and connected The water pipeline is connected, and the inclination angle of the first reflux condenser pipe 3 in this embodiment is 50°.

[0039] The evaporation reflux tank 5 of this embodiment is also a jacketed structure, and a U-shaped pipe 4 is fixed with a bracket inside the evaporation reflux tank 5, and one port of the U-shaped pipe 4 is provided with a funnel sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com