CdSe hollow nanosphere with adjustable size and preparation method thereof

A hollow nano-sized technology, applied in the field of nano-materials, can solve the problems of cumbersome preparation methods, difficult adjustment, and small size range, and achieve the effects of good monodispersity, low cost, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] S1. Weigh Cd(AC) 2 , Se powder, respectively dissolved in benzyl alcohol, stirred for 30min, and then added PVP as the reaction starting solution, wherein the added Cd(AC) 2 , The molar ratio of Se powder and PVP is 3:3:40, Cd(AC) 2 The added concentration in benzyl alcohol is 0.15mM / 20mL. Pour the above solution into a polytetrafluoroethylene liner, then seal the reaction kettle, put the reaction kettle in an oven at 150°C, keep the reaction for 36h, and naturally cool to room temperature;

[0025] S2. Alternately washing the reaction product in step S1 with absolute ethanol and deionized water for 3 cycles to remove reaction residues to obtain CdSe hollow nanospheres.

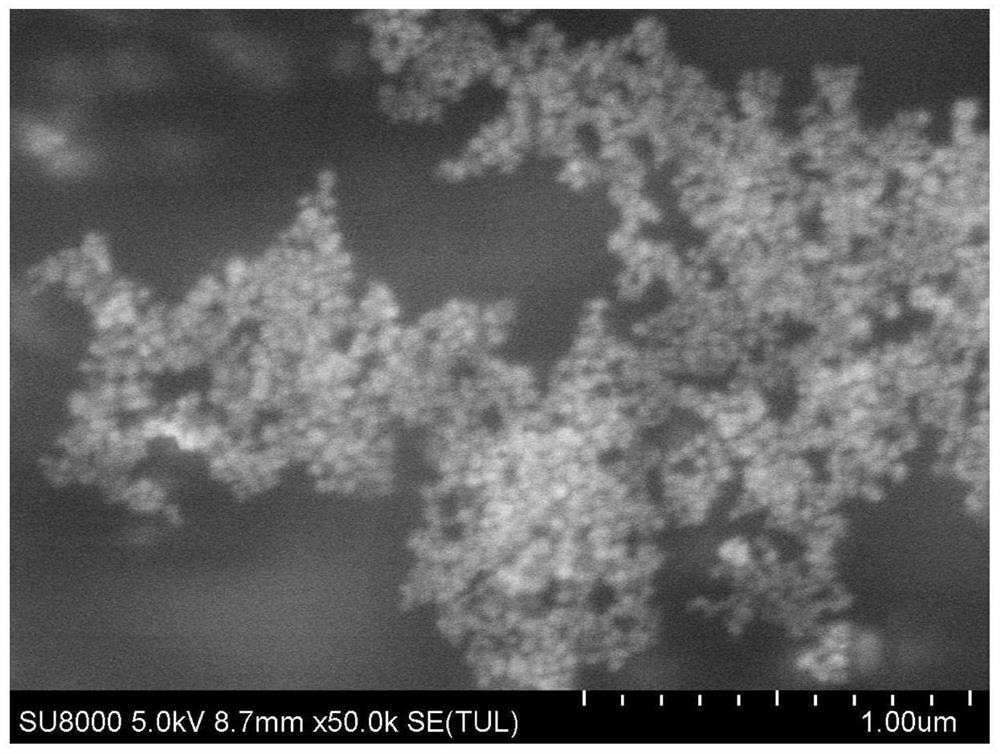

[0026] Scanning electron microscopy of the prepared CdSe hollow nanospheres, the results are as follows figure 1 shown by figure 1 It can be seen that the prepared CdSe hollow nanospheres are monodisperse and uniform in particle size, with a particle size of 30 nm.

Embodiment 2

[0028] S1. Weigh Cd(AC) 2 , Se powder, respectively dissolved in benzyl alcohol, stirred for 30min, and then added PVP as the reaction starting solution, wherein the added Cd(AC) 2 , The molar ratio of Se powder and PVP is 3:3:40, Cd(AC) 2 The added concentration in benzyl alcohol is 0.3mM / 20mL, pour the above solution into a polytetrafluoroethylene liner, then seal the reaction kettle, put the reaction kettle in an oven at 150°C, keep the reaction for 36h, and cool down to room temperature naturally;

[0029] S2. Alternately washing the reaction product in step S1 with absolute ethanol and deionized water for 3 cycles to remove reaction residues to obtain CdSe hollow nanospheres.

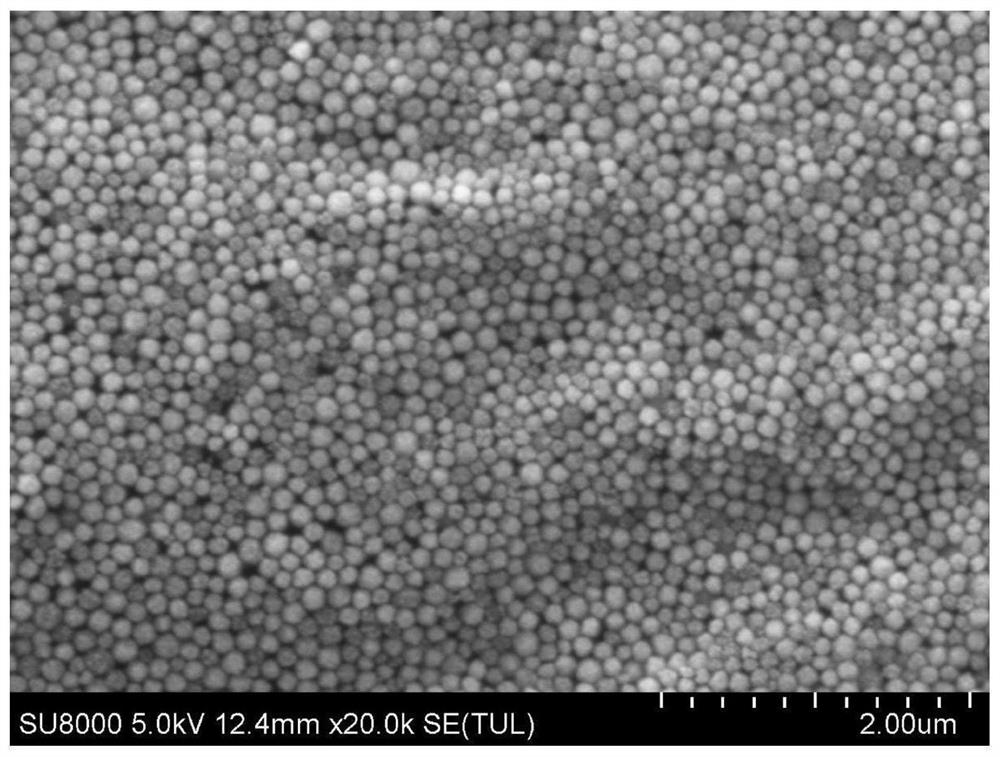

[0030] Scanning electron microscopy of the prepared CdSe hollow nanospheres, the results are as follows figure 2 shown by figure 2 It can be seen that the prepared CdSe hollow nanospheres are monodisperse and uniform in particle size, with a particle size of 140 nm.

Embodiment 3

[0032] S1. Weigh Cd(AC) 2 , Se powder, respectively dissolved in benzyl alcohol, stirred for 30min, and then added PVP as the reaction starting solution, wherein the added Cd(AC) 2 , The molar ratio of Se powder and PVP is 3:3:40, Cd(AC) 2 The added concentration in benzyl alcohol is 0.45mM / 20mL, pour the above solution into a polytetrafluoroethylene liner, then seal the reaction kettle, put the reaction kettle in an oven at 150°C, keep the reaction for 36h, and naturally cool to room temperature;

[0033] S2. Alternately washing the reaction product in step S1 with absolute ethanol and deionized water for 3 cycles to remove reaction residues to obtain CdSe hollow nanospheres.

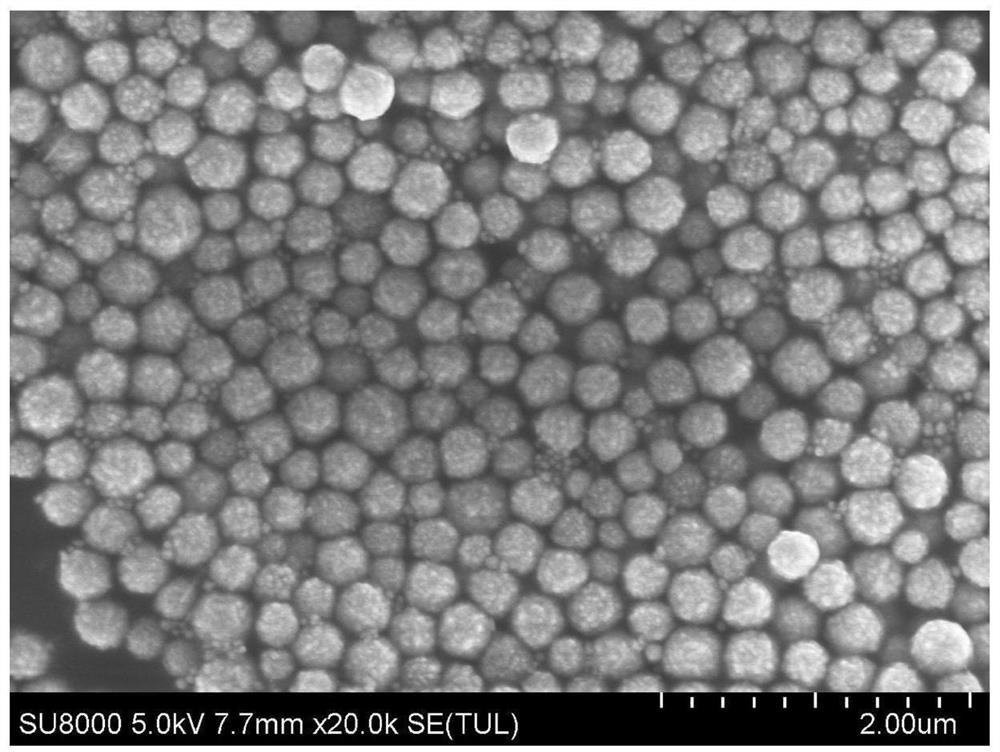

[0034] Scanning electron microscopy of the prepared CdSe hollow nanospheres, the results are as follows image 3 shown by image 3 It can be seen that the prepared CdSe hollow nanospheres are monodisperse and uniform in particle size, with a particle size of 350 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com