A kind of semi-aromatic polyamide and molding composition thereof

A technology of semi-aromatic polyamide and caprolactam, which is applied in the field of engineering plastics, can solve problems such as the difficulty of terephthalic acid reaction, and achieve the effect of good appearance, no lowering of melting point and smooth material strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

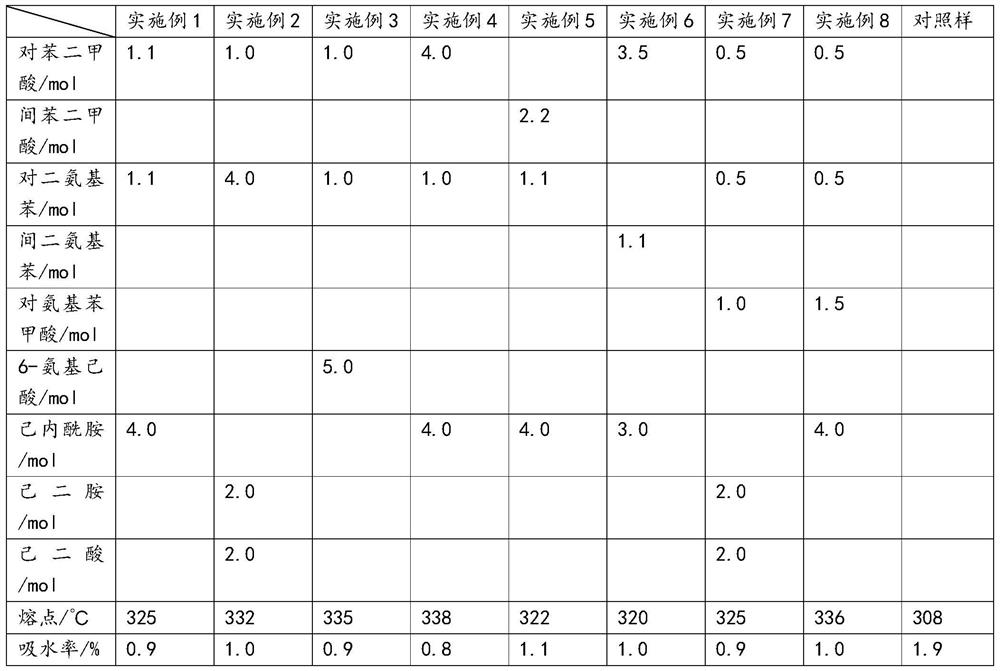

[0038] Process for the preparation of semi-aromatic polyamides

[0039] Add the reaction raw materials into the autoclave according to the ratio in Table 1, then add benzoic acid, zinc acetate and deionized water, and start the stirring device. Vacuumize and fill with nitrogen, repeat 3 times, get rid of the air in the reactor. Heat to 280°C, at this time the pressure will rise to 2.7MPa, maintain this pressure for 3 hours by releasing water vapor, then release the pressure to 0.5MPa, raise the temperature to 320°C and continue the reaction for 4 hours. Raise the temperature to 340°C, pressurize to 0.7MPa with nitrogen, and discharge to obtain a semi-aromatic nylon product.

Embodiment 9

[0041]Mix 1kg of PA66 salt, 166g of terephthalic acid, 108g of p-phenylenediamine, 1g of benzoic acid, and 0.5g of sodium hypophosphite catalyst into the autoclave, add 1kg of deionized water, and start the stirring device. Vacuumize and fill with nitrogen, repeat 3 times, get rid of the air in the reactor. Heat to 300°C, at this time the pressure will rise to 2.7MPa, maintain this pressure for 3 hours by releasing water vapor, then release the pressure to 0.5MPa, raise the temperature to 320°C and continue the reaction for 4 hours. Raise the temperature to 340°C, pressurize to 0.7MPa with nitrogen, and discharge to obtain a semi-aromatic nylon product.

Embodiment 10

[0043] Mix 1 kg of caprolactam, 215.8 g of terephthalic acid, 140.4 g of p-phenylenediamine, 1 g of benzoic acid, and 1 g of sodium hypophosphite catalyst into the autoclave, and start the stirring device. Vacuumize and fill with nitrogen, repeat 3 times, get rid of the air in the reactor. Heated to 300°C, reacted for 3 hours, then raised the temperature to 320°C and continued to react for 4 hours. Raise the temperature to 340°C, pressurize to 0.7MPa with nitrogen, and discharge to obtain a semi-aromatic nylon product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com