Paint remover for removing paint film on surface of tin-plated steel plate for food can and using method thereof

A technology of tin-plated steel plate and paint remover, which is applied in the direction of chemical paint/ink remover and coating, which can solve the problems of construction site and operator hazards, poor environmental performance of solvents, strong volatility, etc., and achieve paint removal High efficiency, good environmental performance, and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

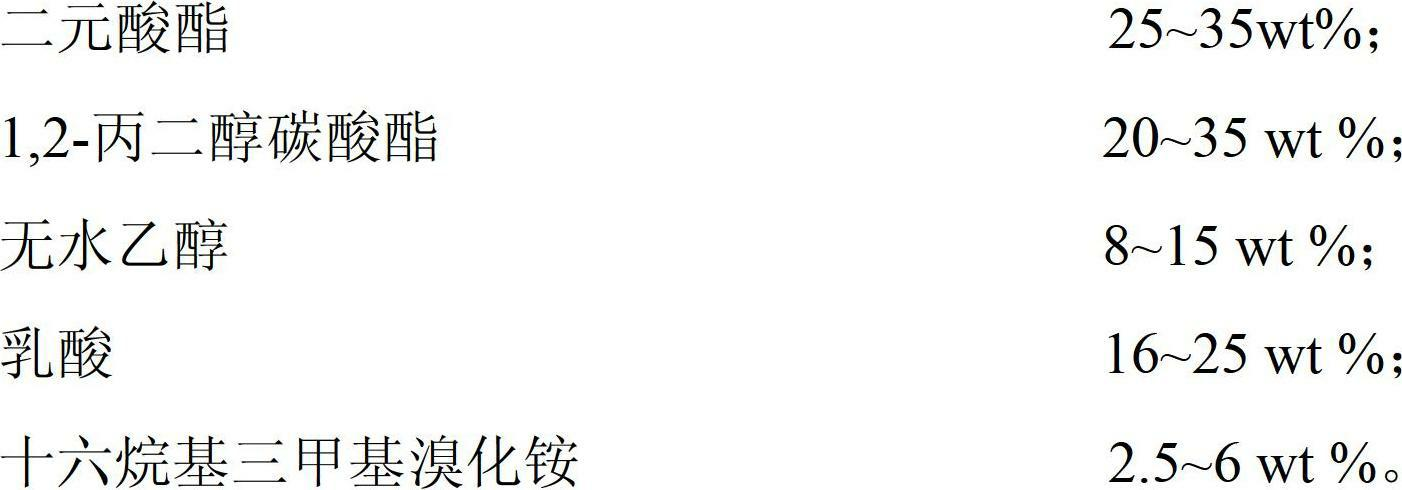

[0026] A paint remover for removing the paint film on the surface of a tinned steel plate for food cans and a use method thereof. The raw materials and contents of the paint remover are: 25~28wt% of dimethyl succinate, 32~35wt% of 1,2-propanediol carbonate, 14~15wt% of absolute ethanol, and 18~20wt% of lactic acid % and cetyltrimethylammonium bromide is 3~5wt%.

[0027] The preparation method of the paint remover for removing the paint film on the surface of the tinned steel plate for food cans described in this embodiment is: firstly carry out batching according to the raw materials and contents of the paint remover, and then divide the raw materials according to the order of solid to liquid Add, then stir at room temperature for 5-15 minutes, mix well and seal for later use.

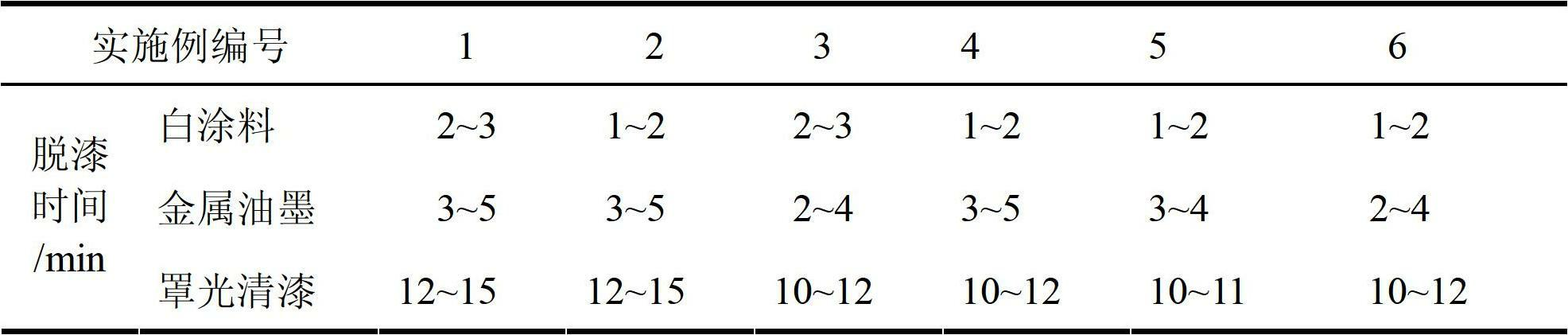

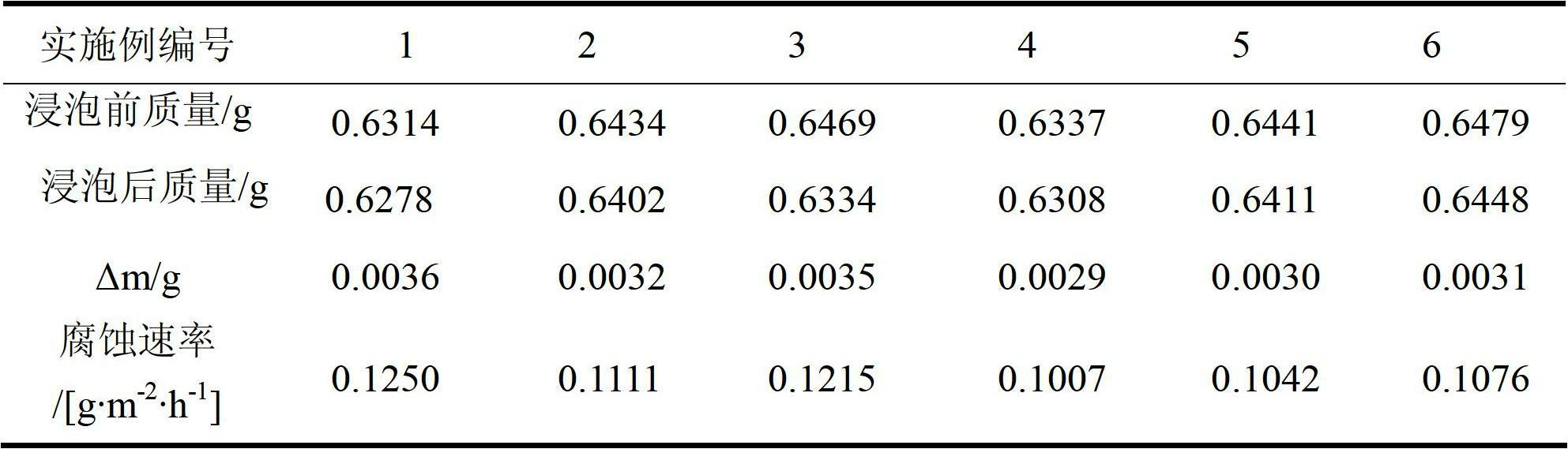

[0028] The method of using the paint remover prepared in this example to remove the paint film on the surface of the tinned steel plate for food cans is: completely immerse the object to be depainted ...

Embodiment 2

[0030] A paint remover for removing the paint film on the surface of a tinned steel plate for food cans and a use method thereof. The raw materials and contents of the paint remover are: 28~30wt% of dimethyl glutarate, 30~32wt% of 1,2-propanediol carbonate, 10~12wt% of absolute ethanol, and 24~25wt% of lactic acid % and cetyltrimethylammonium bromide is 2.5~3wt%.

[0031] The preparation method of the paint stripper described in this embodiment and the usage method of the paint stripper for removing the paint film on the surface of the tinned steel plate for food cans prepared by this method are all the same as in Example 1.

Embodiment 3

[0033] A paint remover for removing the paint film on the surface of a tinned steel plate for food cans and a use method thereof. The raw materials and contents of the paint remover are: 30~33wt% of dimethyl adipate, 25~28wt% of 1,2-propanediol carbonate, 12~13wt% of absolute ethanol, and 23~24wt% of lactic acid % and cetyltrimethylammonium bromide is 4~5wt%.

[0034] The preparation method of the paint stripper described in this embodiment and the usage method of the paint stripper for removing the paint film on the surface of the tinned steel plate for food cans prepared by this method are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com