Fume dehumidification process

A flue gas and process technology, which is applied in the field of flue gas treatment of coal-fired boilers, can solve the problems of high humidity emission and low temperature of flue gas, and achieve the effects of reducing equipment corrosion hazards, facilitating equipment installation, and reducing the accumulation of chloride ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

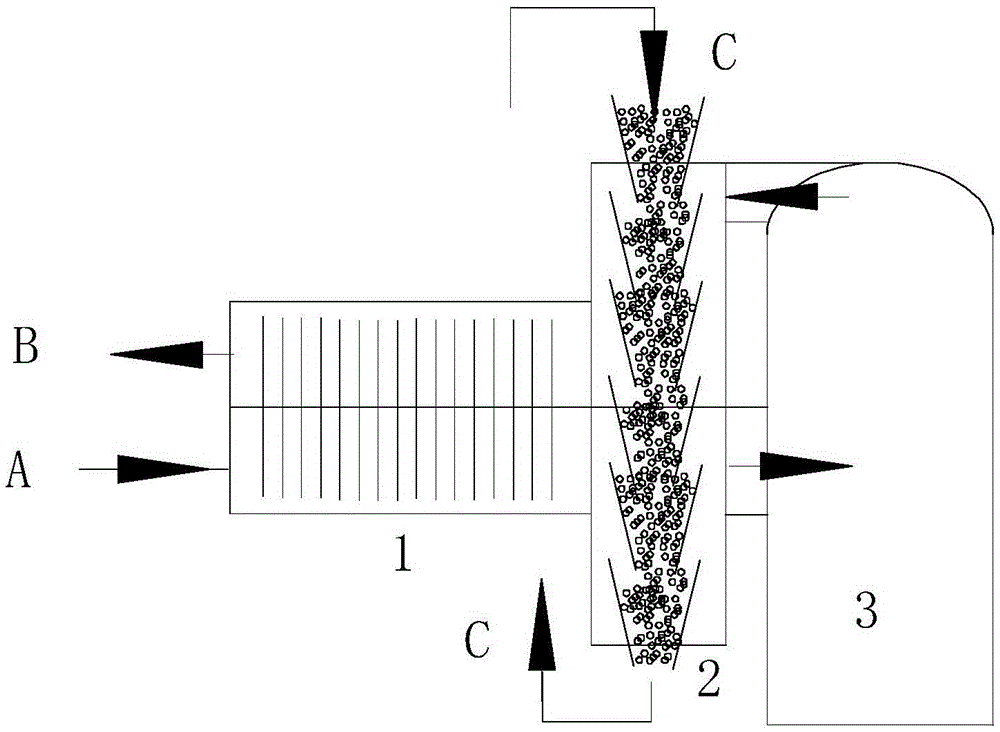

[0022] figure 1 Intermediate flue gas reheater 1, circulating dehumidifier 2, desulfurization island 3; high temperature flue gas A, reheated and purified flue gas B, desiccant C.

[0023] A circulating dehumidifier 2 is added between the desulfurization island 3 and the flue gas reheater 1. The circulating dehumidifier 2 is divided into upper and lower sections, the upper section is connected to the upper layer of the flue gas reheater 1, and the lower section is connected to the lower layer of the flue gas reheater 1; The desiccant C flows in multiple conical funnels connecting the upper and lower sections. In the upper section of the circulating dehumidifier 2, the desulfurized wet flue gas flows through the upper and lower cone annulus and contacts with the dry desiccant. The moisture in the flue gas is absorbed and dried. After being converted into a wet desiccant, it enters the lower section of the circulating dehumidifier 2; in the lower section of the circulating dehum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com