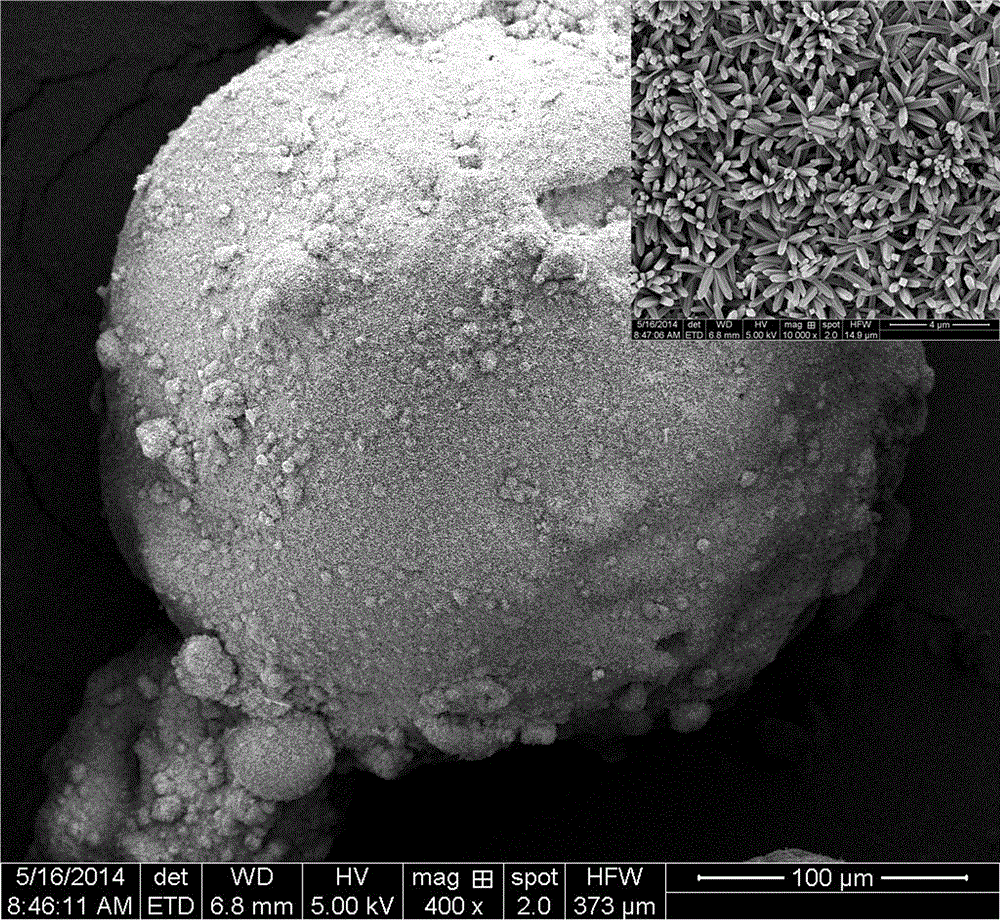

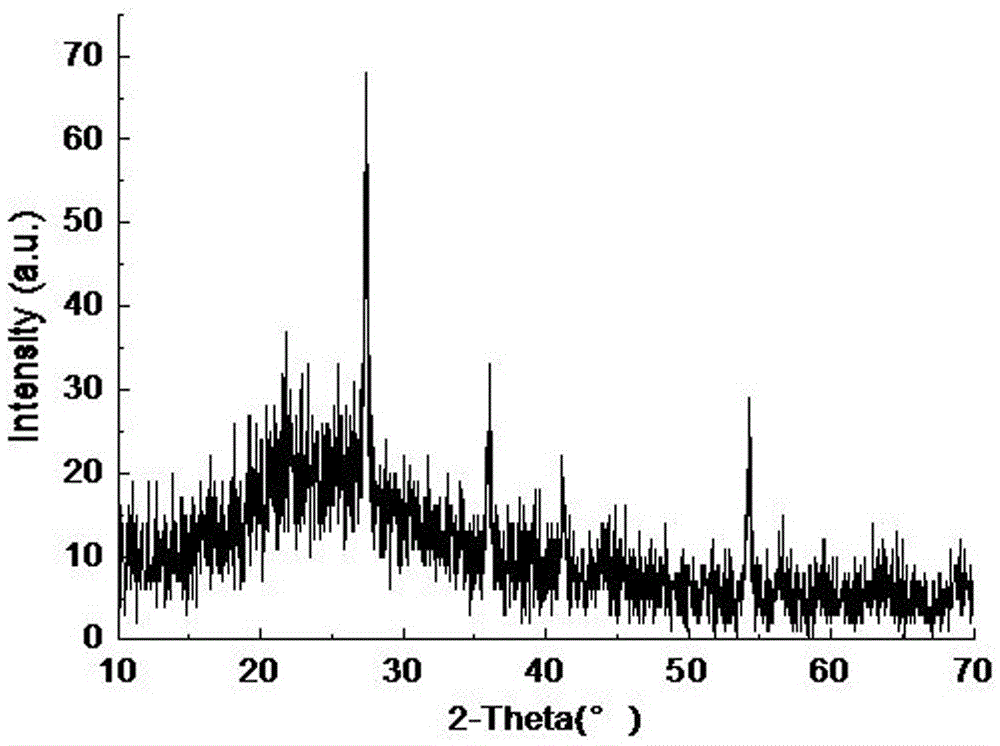

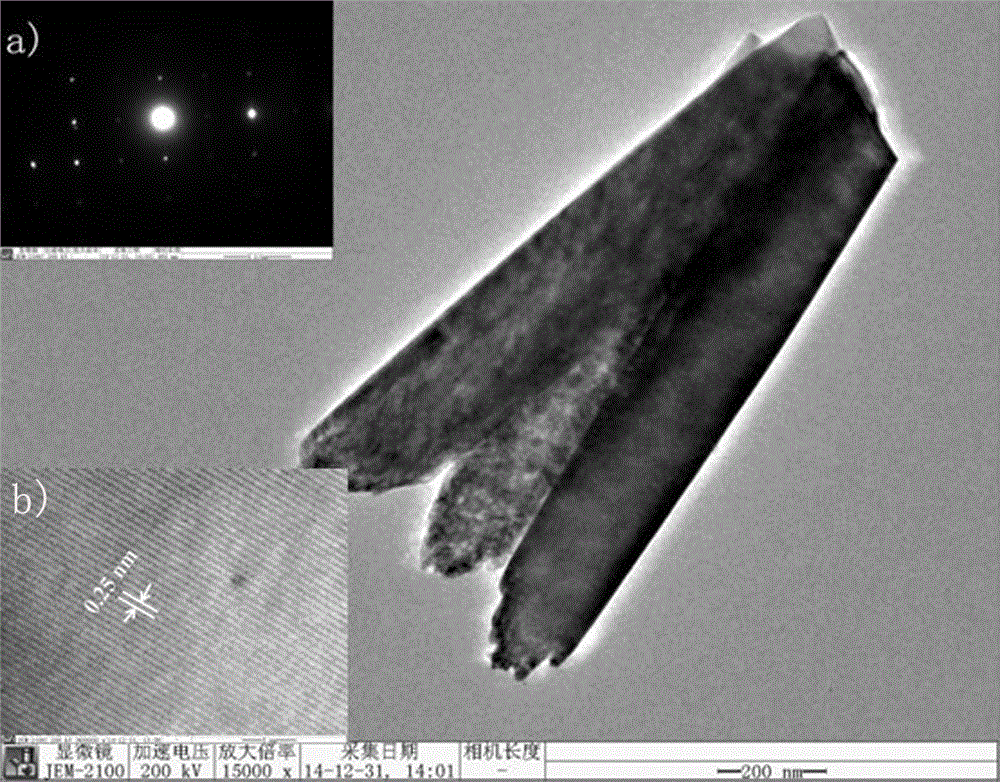

Preparation method of floatable type recoverable photocatalyst based on single-crystal titanium dioxide

A technology of titanium dioxide and photocatalyst, which is applied in the field of photocatalysis, can solve the problems of weak binding force between catalyst and carrier, unsuitability for single crystal titanium dioxide, small surface area of catalyst, etc., achieve good electron-hole separation effect, good catalytic degradation effect, The effect of good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This experimental procedure simply describes the specific preparation process, and the amount of catalyst prepared at a time is related to the volume of the autoclave.

[0027] A floating recyclable photocatalyst based on single crystal titanium dioxide, the preparation method of which is as follows:

[0028] 1) Fully mix the fly ash particles with 1% vinyltriethoxysilane (KH171) ethanol solution, let stand, and separate the floating fly ash particles;

[0029] 2) Transfer the fly ash particles separated in step 1) to an aqueous alcohol solution (the volume ratio of ethanol to water is 49:1), slowly add tetrabutyl titanate to a concentration of 1%, and stir thoroughly. Stand still, separate the floating fly ash particles, dry at 80°C, and then bake at 500°C for 2 hours to obtain fly ash particles loaded with titanium dioxide seeds;

[0030] 3) Prepare a solution of tetrabutyl titanate and concentrated hydrochloric acid at a volume ratio of 1:1, stir well until the syst...

Embodiment 2

[0033] This experimental procedure simply describes the specific preparation process, and the amount of catalyst prepared at a time is related to the volume of the autoclave.

[0034] A floating recyclable photocatalyst based on single crystal titanium dioxide, the preparation method of which is as follows:

[0035] 1) Fully mix the fly ash particles with 1% vinyltriethoxysilane (KH171) ethanol solution, let stand, and separate the floating fly ash particles;

[0036] 2) Transfer the fly ash particles separated in step 1) to an aqueous alcohol solution (the volume ratio of ethanol to water is 49:1), slowly add tetrabutyl titanate to a concentration of 1%, and stir thoroughly. Stand still, separate the floating fly ash particles, dry at 80°C, and then bake at 500°C for 2 hours to obtain fly ash particles loaded with titanium dioxide seeds;

[0037] 3) Prepare a solution of titanium tetrachloride and concentrated hydrochloric acid at a volume ratio of 1:1, stir well until the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com