A photodegradation catalyst for organic sewage treatment and preparation method thereof

A technology of organic sewage and catalyst, applied in the direction of light water/sewage treatment, water/sludge/sewage treatment, physical/chemical process catalyst, etc., can solve the problem of reducing the efficiency of photocatalytic oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

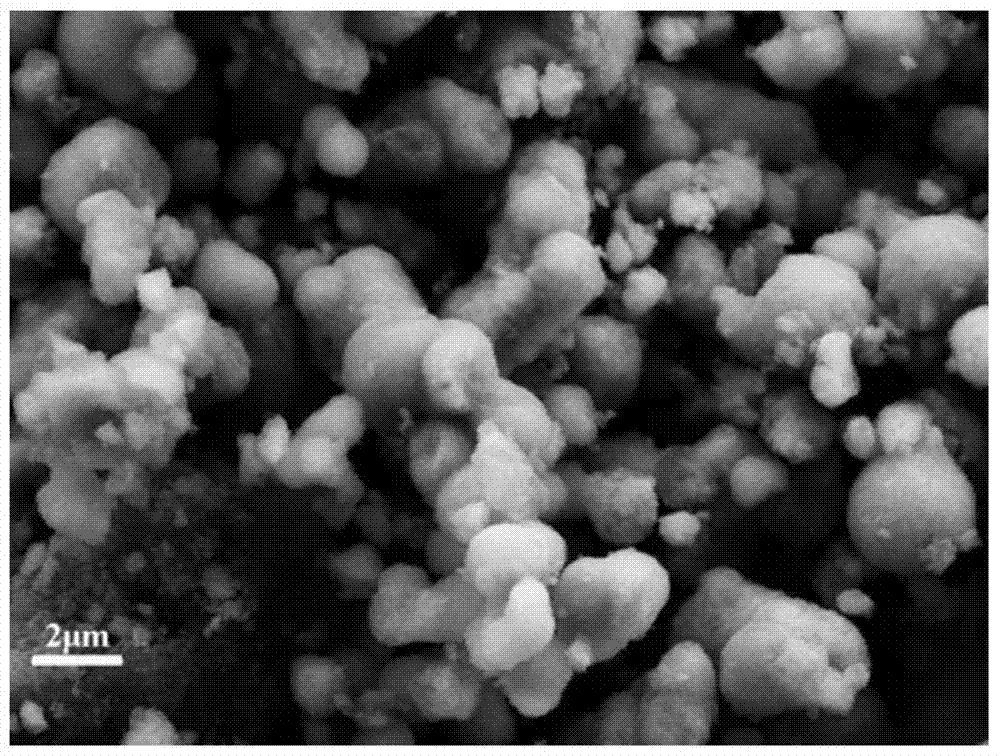

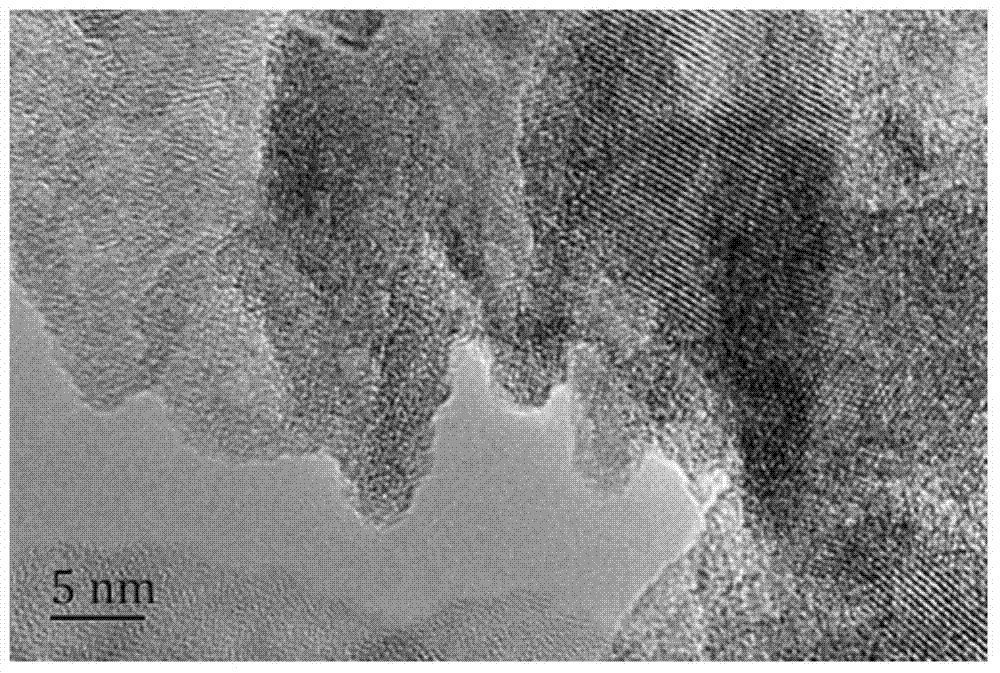

[0019] 100g of melamine was calcined at 520°C for 3 hours, taken out and ground into powder to obtain carbon nitride powder.

[0020] Mix 8ml of n-butyl titanate, 1ml of HF solution (40wt%), 0.2g of carbon nitride powder, and 150ml of isopropanol into a hydrothermal reactor, and react at 180°C for 24h, and the obtained After the suspension was separated, it was washed with water several times, and dried at 90°C to obtain a light yellow powder.

[0021] Disperse more than 0.2 g of catalyst powder by ball milling in 10 mL of water to prepare a dispersion slurry, then add the slurry to 1 L of organically polluted water with a solubility of 10 mg / mL (the pollutant is methyl blue), and place it under control Strength is 0.51W / m 2 @340nm Q-SUN aging box for 2h, the residual amount of organic pollutants is 3.5% of the initial solubility.

Embodiment 2

[0023] 100g of melamine was calcined at 520°C for 3h, taken out and ground into powder to obtain carbon nitride powder, and then calcined at 550°C for 0.5h.

[0024] Mix 8ml of n-butyl titanate, 1ml of HF solution (40wt%), 0.1g of carbon nitride powder, and 150ml of isopropanol into a hydrothermal reactor, and react at 180°C for 24h, and the resulting After the suspension was separated, it was washed with water several times, and dried at 90°C to obtain a light yellow powder.

[0025] Disperse more than 0.2 g of catalyst powder by ball milling in 10 mL of water to prepare a dispersion slurry, then add the slurry to 1 L of organically polluted water with a solubility of 10 mg / mL (pollutant is methyl blue), and place under control Strength is 0.51W / m 2 @340nm Q-SUN aging box for 2h, the residual organic pollutants are 3.0% of the initial solubility.

Embodiment 3

[0027] 100g of melamine was calcined at 520°C for 3 hours, taken out and ground into powder to obtain carbon nitride powder.

[0028] Mix 8ml of tetraisopropyl titanate, 1ml of HF solution (40wt%), 0.1g of carbon nitride powder, and 150ml of isobutanol into a hydrothermal reactor, and react for 24 hours at 180°C. The obtained suspension was separated, washed with water several times, and dried at 90° C. to obtain a light yellow powder.

[0029] More than 0.3g of catalyst powder ball milling is dispersed in the water of 10ml and is prepared into dispersion slurry, then this slurry is added in the water body of 20mg / mL organic pollution (pollutant is phenol) by the solubility of 1L, is placed in the care intensity of 0.51W / m 2 @340nm Q-SUN aging box for 2h, the residual amount of organic pollutants is 3.6% of the initial solubility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com