Quantum dot, preparation method thereof and quantum dot film

A technology of quantum dots and boiling points, applied in the field of quantum dots and their preparation, can solve the problems of low fluorescence efficiency of quantum dots, and achieve the effects of maintaining light conversion efficiency, improving optical utilization, and enhancing light absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

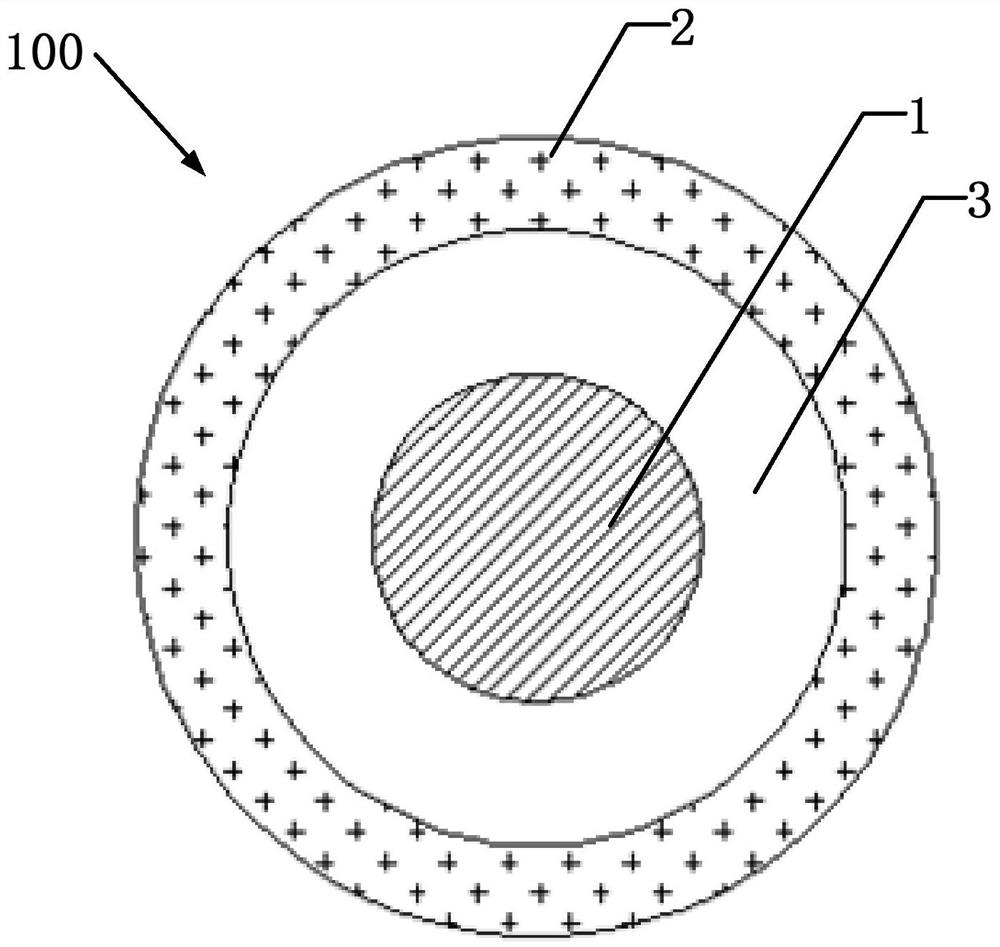

[0036] like figure 1 As shown, this embodiment provides a quantum point 100. The quantum dot 100 includes a quantum dot core 1 and a metal shell 2.

[0037] Among them, quantum dot core 1 is divided into red quantum dot core and green quantum dot core. Among them, the materials of the red quantum dot include: cdse, cd 2 One of Setries and INAs; the materials of the green quantum dot include: Zncdse 2 , INP and CD 2 One of SSE. In this embodiment, the material of the quantum dot core 1 is CDSE. Wherein, the amount of the quantum dot core 1 ranges from 1 nm to 10 nm.

[0038] Wherein, the metal shell 2 covers the quantum dot core 1. The material of the metal shell 2 includes Ag, Ag @ SiO 2 , AG @ Tio 2 One or more of AG @ PS, AG @ PMMA and AG @ PE. In this embodiment, the material of the metal shell 2 is Ag, and the absorption peak of Ag ranges from 430 nm to 500 nm. The outer wall of the metal shell 2 ranges from 100 nm to 150 nm. The light absorption efficiency of the quantum poin...

Embodiment 2

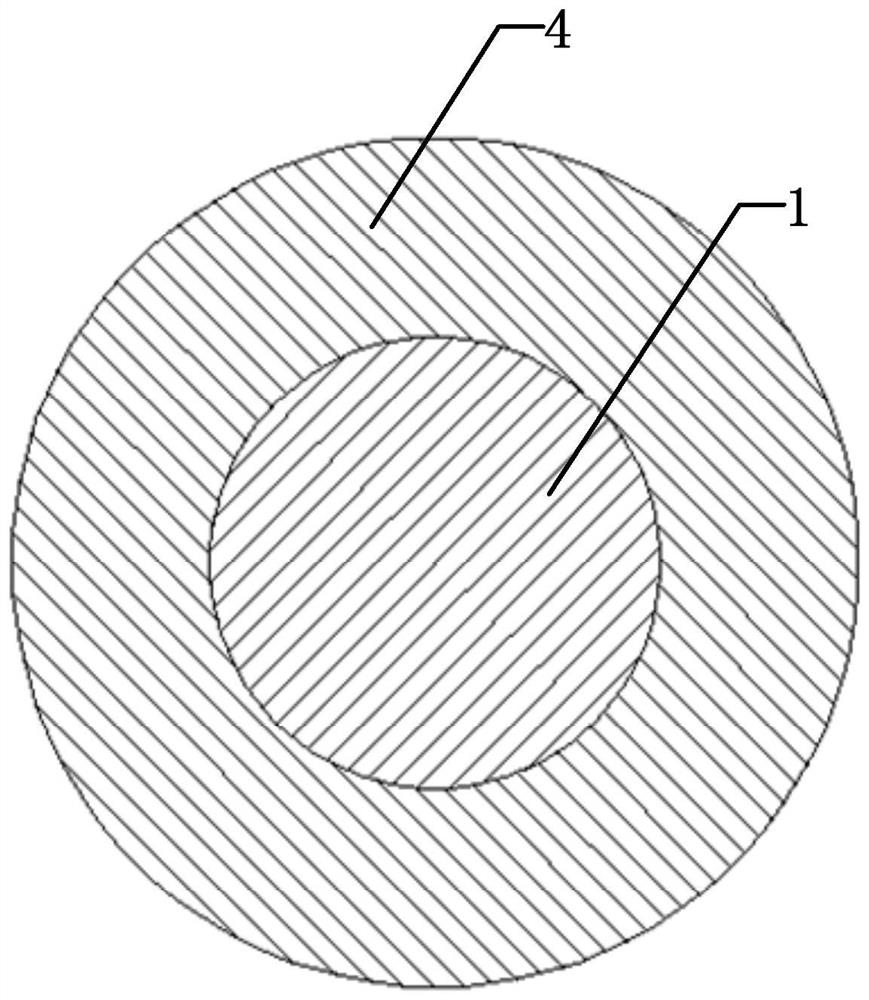

[0064] like Figure 4 As shown, this embodiment provides a quantum point 100. The quantum dot 100 includes: quantum dot core 1, casing 5, and metal shell 2.

[0065] Among them, quantum dot core 1 is divided into red quantum dot core and green quantum dot core. Among them, the materials of the red quantum dot include: cdse, cd 2 One of Setries and INAs; the materials of the green quantum dot include: Zncdse 2 , INP and CD 2 One of SSE. In this embodiment, the material of the quantum dot core 1 is CDSE. Wherein, the amount of the quantum dot core 1 ranges from 1 nm to 10 nm.

[0066] Wherein, the casing 5 is covered with the outer wall of the quantum dot core 1. The material of the casing 5 is a wide band gap material comprising cds, znse, zncds. 2 One or more of ZnS and ZnO. In this embodiment, the material of the casing 5 is ZnS. Wherein, the thickness of the casing 5 ranges from 0.5 nm to 10 nm. By coating the casing 5 on the outer wall of the quantum dot core 1, the relief of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com