Preparation method of ferric-carbon internal electrolysis filler

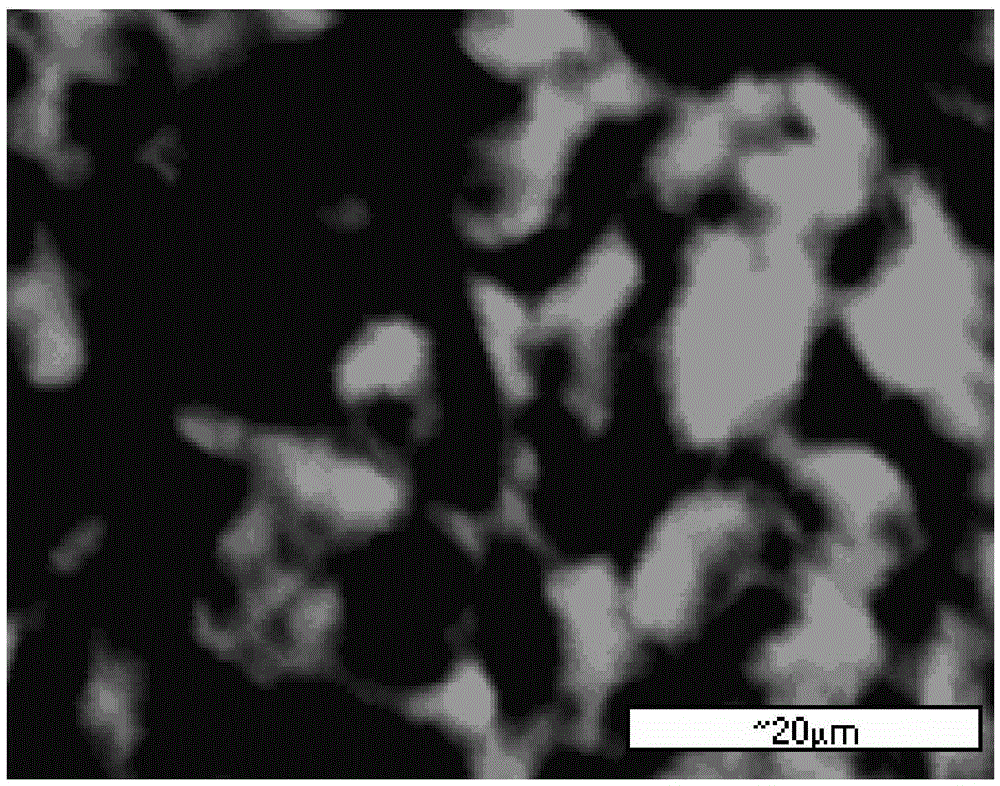

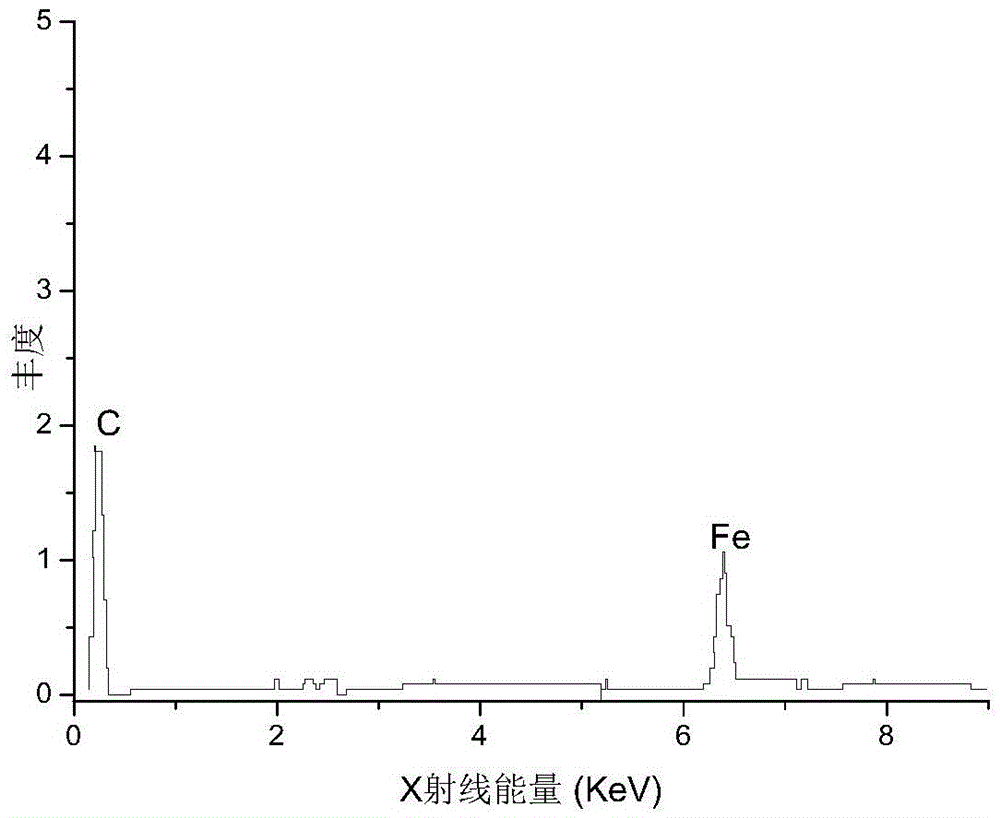

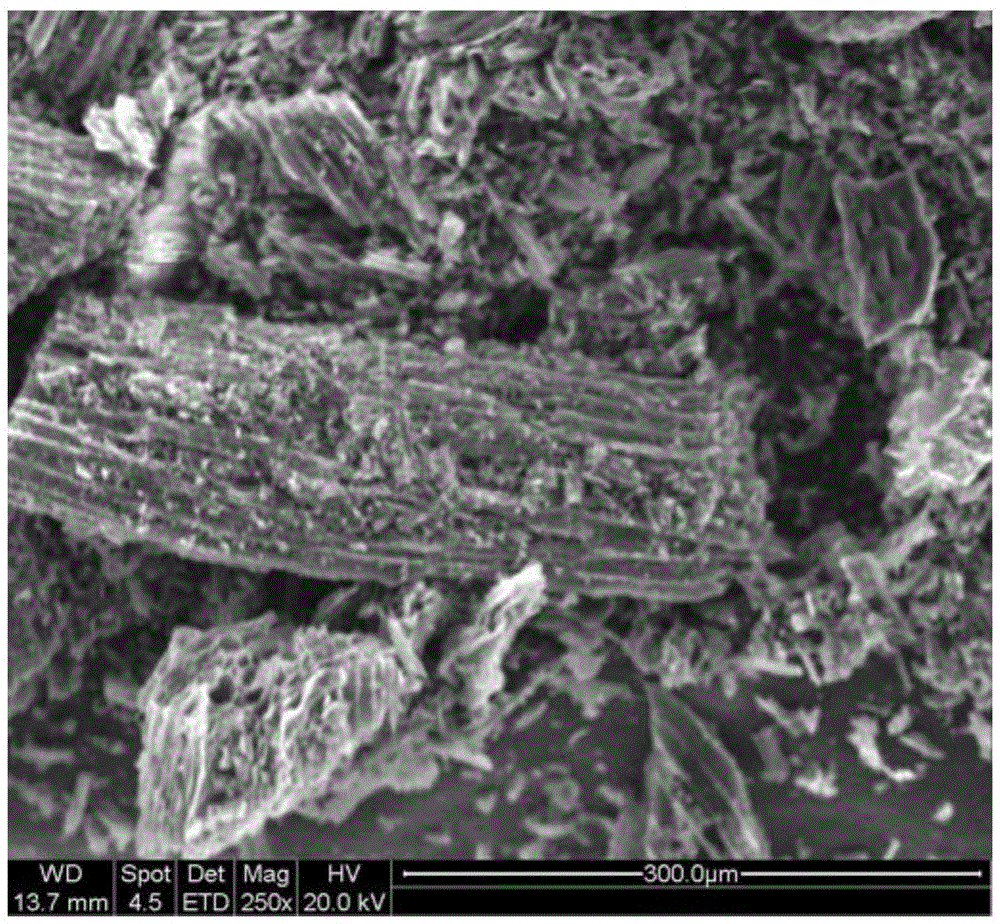

An internal electrolysis, iron and carbon technology, applied in chemical instruments and methods, natural water treatment, water/sewage treatment, etc., can solve the problems of uneven iron powder, low reaction efficiency, etc., to increase the specific surface area of the reaction, improve the reaction Efficiency, the effect of solving the underdeveloped pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of electrolytic filler in iron carbon, specifically comprising the following steps:

[0034] 1) Get 50g of oil sludge from the magnetic rod filter of the cold-rolled emulsion workshop section and place it in 2000g of high-volatile gas-coal powder, and fully mix the two with a mixer; the components in the cold-rolled oil sludge are by mass The percentages are: 22% of mineral oil, 15% of vegetable oil, 40% of iron, 3% of surfactant, and 20% of water; the particle size of high volatile gas coal powder is 90-150 microns;

[0035] 2) Put the mixture obtained in step 1) into a heating furnace to raise the temperature, and when the temperature reaches 100° C., feed N into the heating furnace. 2 , continue to heat the heating furnace until the temperature rises to 900°C, and keep the heating furnace at 900°C; 2 , so that the furnace temperature is cooled to 100 ° C; when the furnace temperature is cooled to 100 ° C, stop feeding nitrogen until the heating ...

Embodiment 2

[0038] A preparation method of electrolytic filler in iron carbon, specifically comprising the following steps:

[0039] 1) Take 50g of oil sludge from the magnetic rod filter of the cold-rolled emulsion workshop section and place it in 1000g of high-volatile gas coal, and fully mix the two with a stirrer; the components in the cold-rolled oil sludge are by mass percentage Calculated as: 30% mineral oil, 10% vegetable oil, 40% iron, 5% surfactant, 15% water; the particle size of high volatile gas coal powder is 100-200 microns;

[0040] 2) Put step 1) gained mixture into heating furnace, pass into N in heating furnace 2 For protection, heat preservation after the temperature rises to 800 ° C; after 1.5 hours of heat preservation, keep N 2 In the case of continuous feeding, the furnace temperature is gradually cooled to room temperature to obtain iron-doped activated carbon, that is, to obtain the electrolytic filler in iron-carbon;

[0041] 3) The iron-carbon internal electr...

Embodiment 3

[0043] A preparation method of electrolytic filler in iron carbon, specifically comprising the following steps:

[0044] 1) Take 50g of oil sludge from the magnetic rod filter of the cold-rolled emulsion workshop section and place it in 2500g of high-volatile gas coal, and fully mix the two with a mixer; the components in the cold-rolled oil sludge are by mass percentage Calculated as: 20% of mineral oil, 10% of vegetable oil, 57% of iron, 3% of surfactant, and 15% of water; the particle size of high volatile gas coal powder is 200-300 microns;

[0045] 2) Put the mixture obtained in step 1) into a heating furnace to raise the temperature, and when the temperature reaches 100° C., feed N into the heating furnace. 2 , continue to heat the heating furnace until the temperature rises to 850°C, and keep the heating furnace at 850°C; 2 , so that the furnace temperature is cooled to 100 ° C; when the furnace temperature is cooled to 100 ° C, stop feeding nitrogen until the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com