Seawater-sea sand concrete

A technology for concrete and sea sand, applied in the field of building materials, can solve problems such as being unable to be used for preparation, and achieve the effects of low cost, promotion of ecological environment protection, and improvement of work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a kind of seawater sea sand concrete, and its raw material components are respectively by mass parts: cement 12.5kg, seawater 6.5kg, sea sand 32.5kg, stone 43kg, fly ash 4.5kg, water reducer 0.4kg, Air-entraining agent 0.002kg, retarder 0.01kg, sacrificial agent 0.005kg.

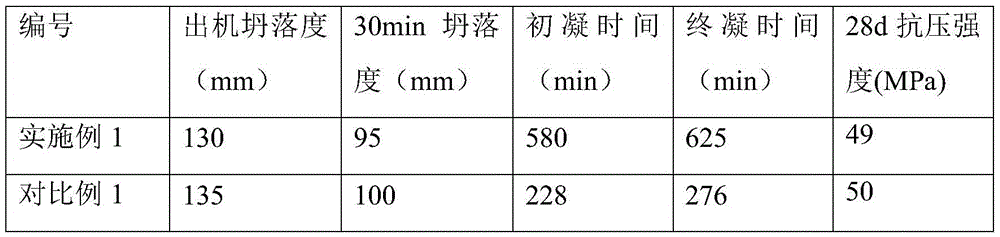

[0028] After accurately weighing the above-mentioned raw materials, put them into a twin-shaft forced mixer and mix them evenly for 2 minutes, then conduct a fresh mixing performance test, and shape them into 150*150*150mm 3 The cube specimens are used for strength testing. The test results are shown in Table 1:

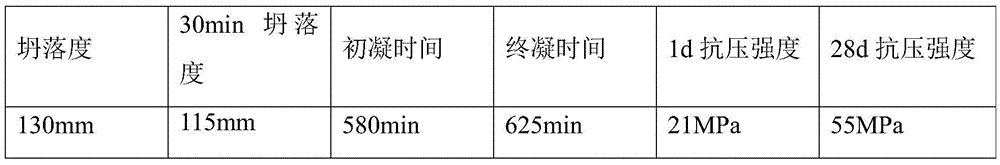

[0029] The concrete physical property of table 1 embodiment 1

[0030]

[0031] The test results show that the slump of the concrete reaches 130mm, the construction performance is good, the initial and final setting times are reasonable, and the construction is not affected, the early strength increases rapidly, and the 28d strength meets the requirements of C50...

Embodiment 2

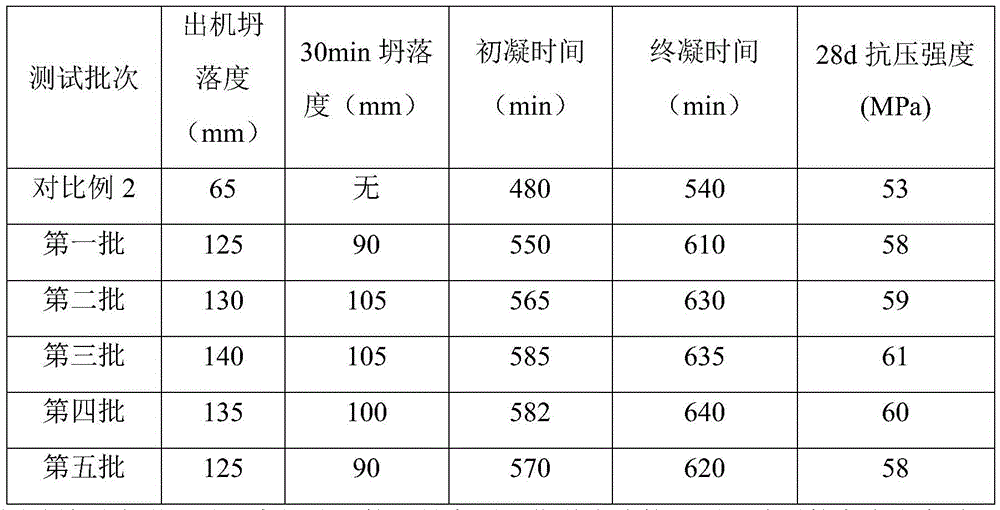

[0038] This embodiment provides a kind of seawater sea sand concrete, its raw material components are measured by mass parts: cement 15kg, seawater 7kg, sea sand 33kg, stone 42.4kg, fly ash 1.5kg, slag powder 4kg, water reducing agent 0.6kg, Air-entraining agent 0.02kg, retarder 0.01kg, including sacrificial agent; 5 batches of experiments were carried out, the difference is that the amount of sacrificial agent added is different, respectively 0.003kg, 0.004, 0.005kg, 0.006kg, 0.007kg. Before mixing the above raw materials, accurately weigh the sacrificial agent, add the sacrificial agent and mix for 2 minutes, then select different regions, seawater and sea sand for experiments to test the fresh performance and early performance of different batches of concrete, and measure the results as shown in Table 3. Among them, the first batch to the fifth batch correspond to seawater and sea sand concrete with sacrificial agent addition amounts of 0.003kg, 0.004, 0.005kg, 0.006kg, and...

Embodiment 3

[0045] This embodiment provides a kind of seawater sea sand concrete, its raw material components in parts by mass: 21kg of cement, 8kg of seawater, 36kg of sea sand, 42kg of stone, 4kg of fly ash, 3kg of slag powder, 0.8kg of water reducing agent, air-entrained Agent 0.04kg, retarder 0.01%, sacrificial agent 0.006kg. After accurately weighing the above-mentioned raw materials, put them into a twin-shaft forced mixer and mix them evenly for 2 minutes, then conduct a fresh mixing performance test, and shape them into 150*150*150mm 3 The cube specimens are used for strength testing. The test results are shown in Table 4:

[0046] The concrete physical property of table 4 embodiment 3

[0047]

[0048] The test results show that the antifreeze performance of concrete (mass loss rate after 300 times of freezing and thawing is 2.2%, and relative dynamic modulus of elasticity is 94%) meets the requirements of national standards after appropriately increasing the amount of induc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Chloride diffusion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com