A kind of preparation method of refractory castable binder for strong alkali environment

A technology of refractory castables and binders, applied in the field of refractory castables, can solve the problems of low use temperature, long hardening time, low demoulding and drying strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

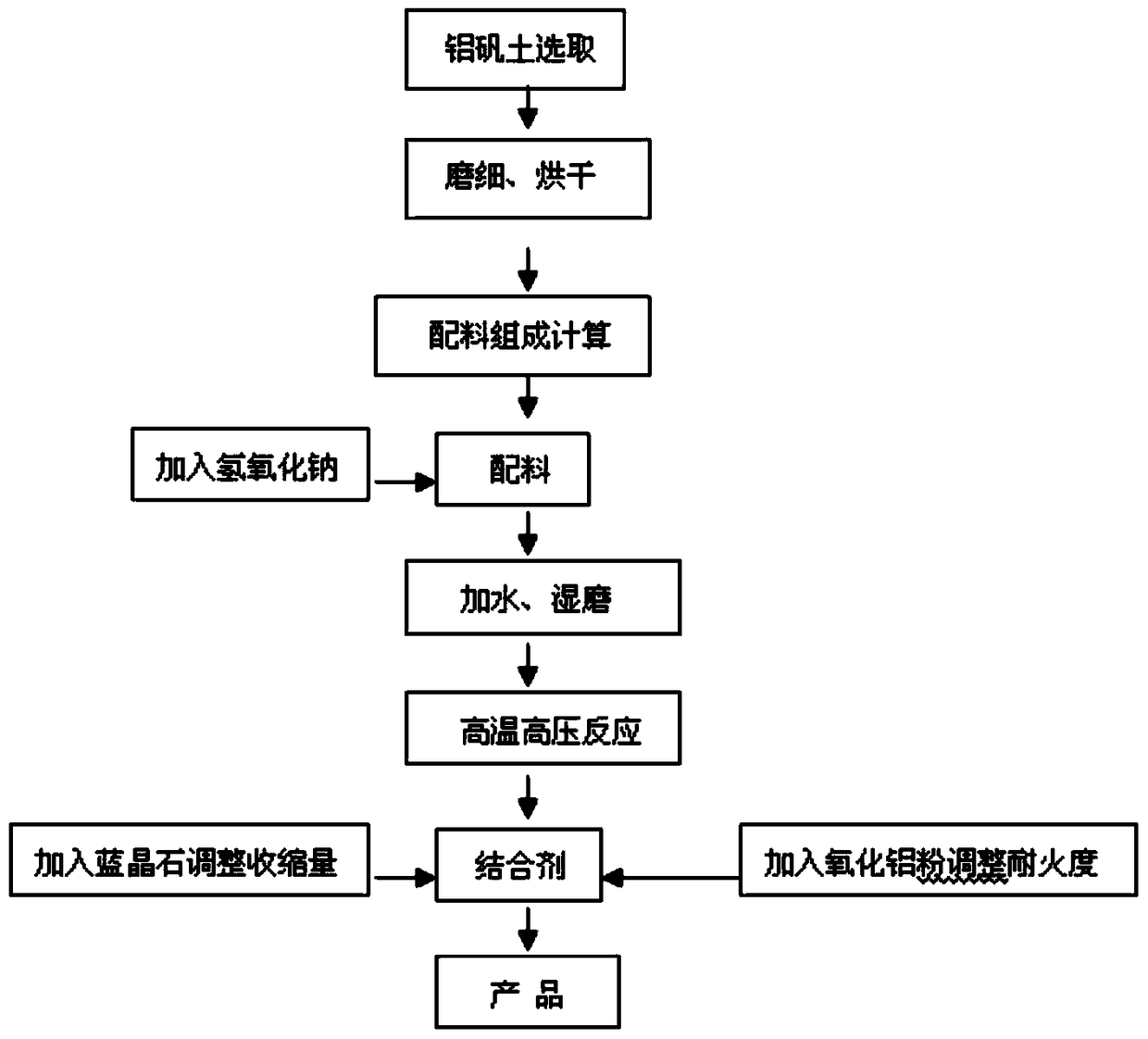

Method used

Image

Examples

Embodiment 1

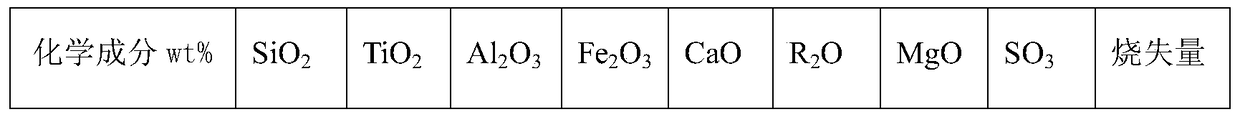

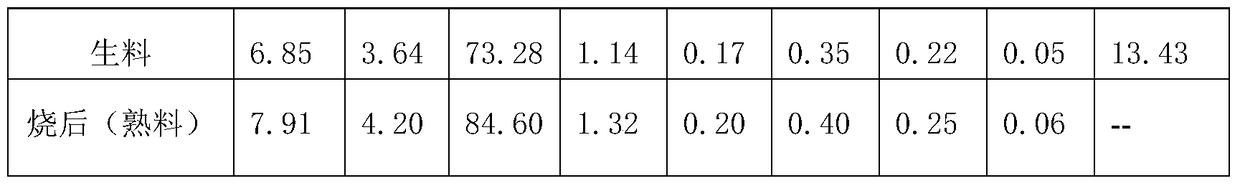

[0024] Take high-quality bauxite from open mining in the eastern section of Jiajiawa, Mianchi, grind it through a 325 mesh sieve, and dry it with a sieve allowance of ≤10%. The chemical composition analysis results (wt%) are as follows:

[0025] Table 1

[0026]

[0027]

[0028] al 2 o 3 =73.28%, SiO 2 =6.85%, Al 2 o 3 / SiO 2 =10.7, Fe 2 o 3 Content less than 1.5%, CaO content less than 1.0%, SO 3 The content is less than 0.2%; it meets the chemical composition conditions of raw materials.

[0029] Ingredients composition calculation

[0030] NaOH→Na 2 O: The conversion factor is 0.775;

[0031] Bauxite (raw meal): conversion factor is 0.8657;

[0032] Weigh and dry bauxite fine powder raw meal 100kg / 0.8657=115.5kg (100kg after burning); 2 o 3 84.60kg, according to Na 2 O / Al 2 o 3 = 0.7 ingredients;

[0033] Join Na 2 The amount of O is 59.22kg, and the NaOH conversion coefficient is 0.775, that is, adding NaOH is: 59.22kg / 0.775=76.41kg

[0034] The ...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is: by Na 2 O / Al 2 o 3 =0.6 ingredients; heat and stir for 3 hours at 150°C and working pressure of 0.3Mpa to prepare the binder.

[0039] The binder prepared in this example is mixed with burnt gemstone aggregate and fine powder with an alumina content of 42%, and can be cured within 24 hours in a natural environment. After drying at 110°C, the flexural bonding strength is 14.8Mpa, which is 61% higher than that of water glass as a binder, and the refractoriness of the castable reaches 1750°C, which is 380°C higher than that of water glass castable. Its construction and high temperature performance are obviously better than water glass castables.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com