A hanger for chemical plating

A technology of electroless plating and hanger, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., and can solve the problem of mass production of difficult-to-resistance copper foil, affecting the uniformity of resistance plating, and low thickness of copper foil, etc. problems, to achieve the effect of mass production, easy to use widely, and increase the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

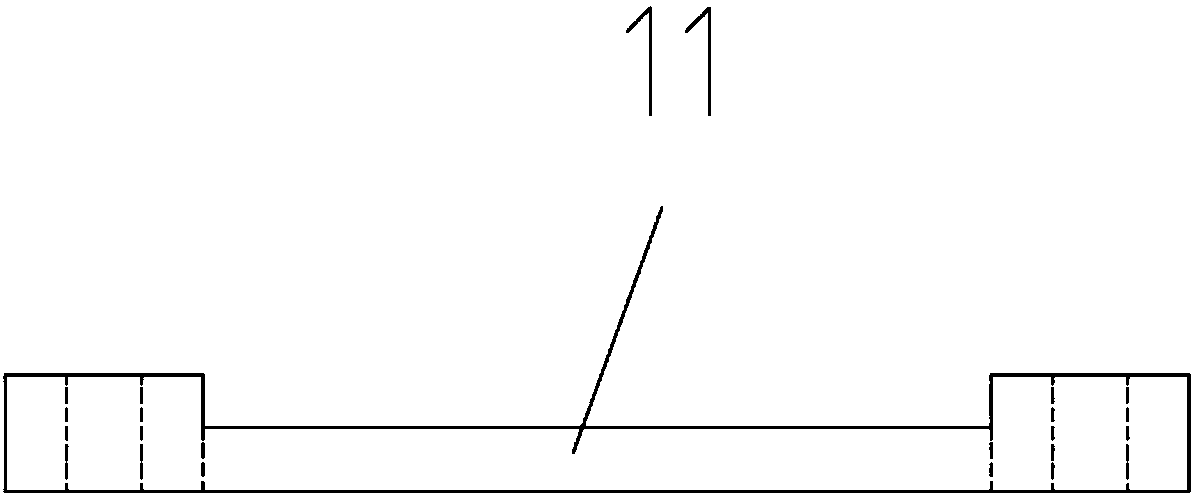

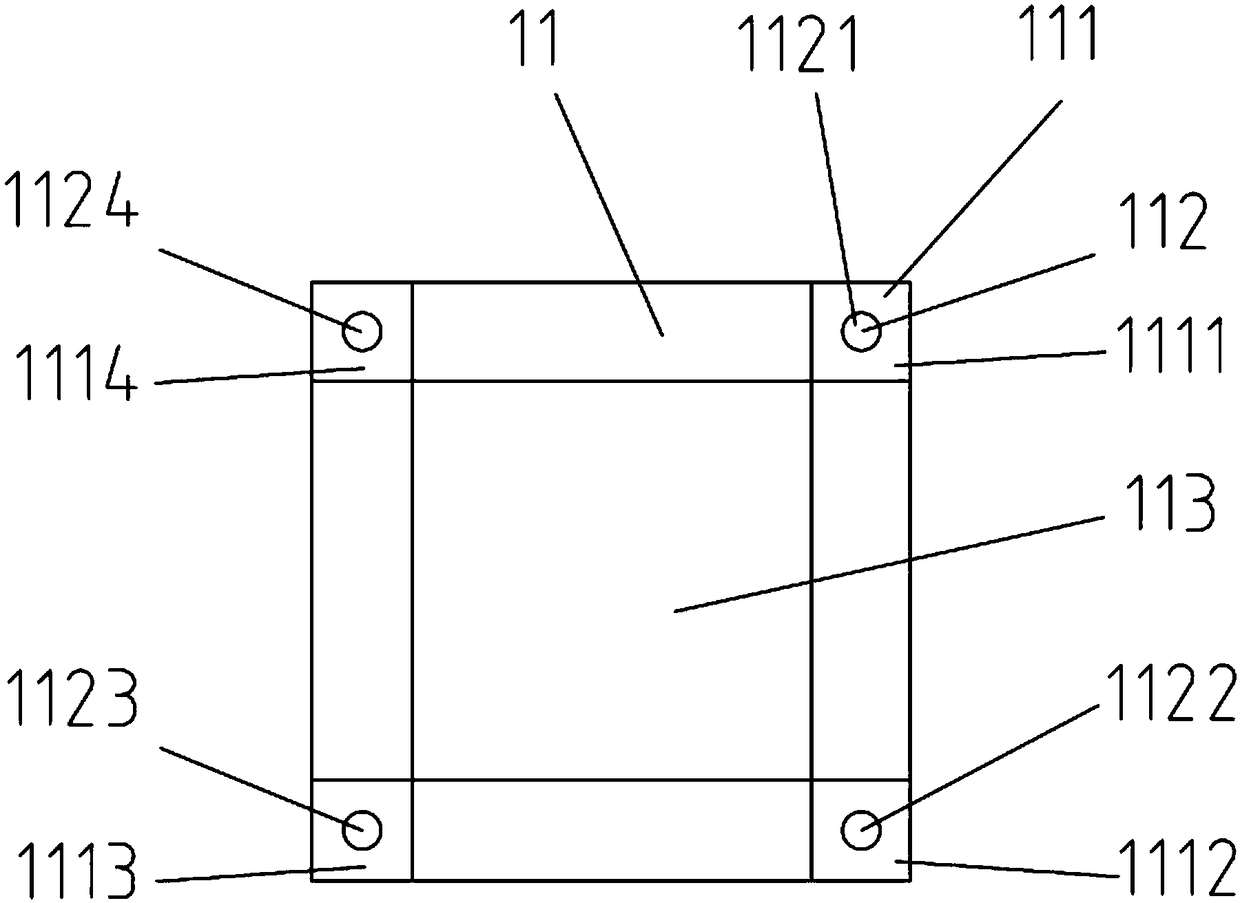

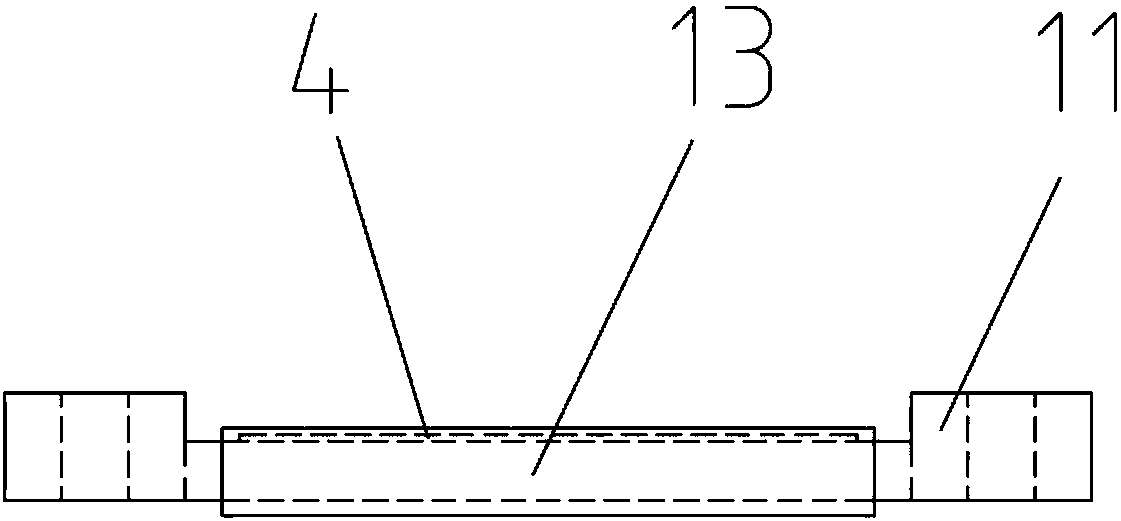

[0035] This embodiment discloses a hanger for electroless plating, such as Figure 1~4 , Figure 5 , Figure 7 As shown, it includes:

[0036] Clamping part 1, it comprises a plurality of substrates 11, substrate fixing device 12 and plating parts fixing device 13 that place plated part 4 usefulness, substrate 11 is provided with boss 111, and boss 111 is provided with through hole 112, and substrate 11 is also provided with a hollowed-out area 113, and the plated parts 4 on the fixed substrate 11 are fixed by the plated part fixing device 13. A plurality of substrates 11 are stacked and the plated parts 4 on the substrate 11 are isolated from each other. A plurality of stacked substrates 11 are bound together to form a clamping portion 1;

[0037] The accommodating part 2 includes a basket 21, the holding part 1 is placed in the basket 21, and the basket 21 plays a role in containing and supporting the whole holding part 1 (including the parts on the holding part 1) in the...

Embodiment 2

[0049] This embodiment discloses another hanger for electroless plating, such as Figure 1~4 , Figure 6 , Figure 8 Shown, its main difference with embodiment 1 is:

[0050] In this embodiment, eight substrates 11 are stacked one by one, and a boss 111 is provided on one side of each substrate 11, the boss 111 of the uppermost substrate 11 faces downward, and the bosses 111 of the remaining substrates 11 all face upward. The plating fixtures 13 on each substrate 11 are on the same vertical plane. By stacking the substrates 11 in this way, each plating piece 4 on each substrate 11 can be protected by the substrate 11 from external damage, which is beneficial to improve the effect of electroless plating.

[0051] The rest of the structure and parts connection relationship of the electroless plating hanger disclosed in this embodiment are completely consistent with those in Embodiment 1, and will not be repeated here.

[0052] In order to facilitate a better understanding of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com