Metal or alloy shell and manufacturing method thereof

A production method and alloy technology, applied in metal processing equipment, manufacturing tools, decorative art, etc., can solve the problems of affecting the appearance of the shell and difficult to cover the defects of metal surface materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

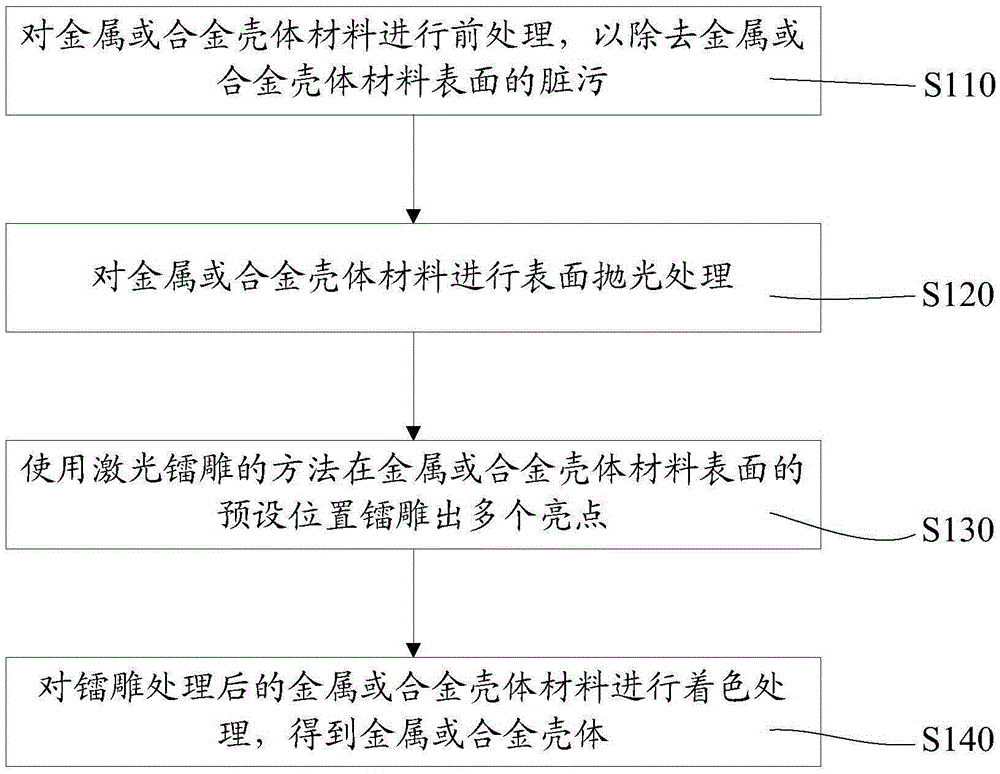

Method used

Image

Examples

Embodiment 1

[0045] Fabrication of aluminum alloy shell with flash point effect

[0046] 1. First, pre-treat the surface of the aluminum alloy material.

[0047] The aluminum alloy material is decontaminated and degreased in the cleaning tank, and then alkali-etched in the alkali tank, and then enters the neutralization tank after being washed with water, and then washed with water after neutralization.

[0048] 2. The surface of the aluminum alloy material is polished to improve the metal texture of the post-treatment.

[0049] 3. Perform metal surface treatment such as sandblasting or wire drawing on the aluminum alloy material after surface polishing.

[0050] 4. Use a laser engraving machine to engrave bright spots of 0.02mm-1mm on the sandblasted or wire-drawn aluminum alloy material.

[0051] 5. Perform anodic oxidation treatment on the aluminum alloy material after laser engraving treatment in an anodic oxidation bath.

[0052] 6. Put the anodized aluminum alloy material into the...

Embodiment 2

[0054] Fabrication of stainless steel housing with flash point effect

[0055] 1. First, pre-treat the surface of the stainless steel material.

[0056] The stainless steel material is decontaminated and degreased in the cleaning bath.

[0057] 2. The surface of the stainless steel material is polished to improve the metal texture of the post-treatment.

[0058]3. Sandblasting the polished stainless steel material.

[0059] 4. Use a laser engraving machine to engrave bright spots of 0.02mm-1mm on the sandblasted stainless steel material.

[0060] 5. After cleaning, perform PVD coloring treatment on the stainless steel material after laser engraving.

[0061] 6. According to the requirements, the anti-fingerprint coating is plated on the colored stainless steel material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com